- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

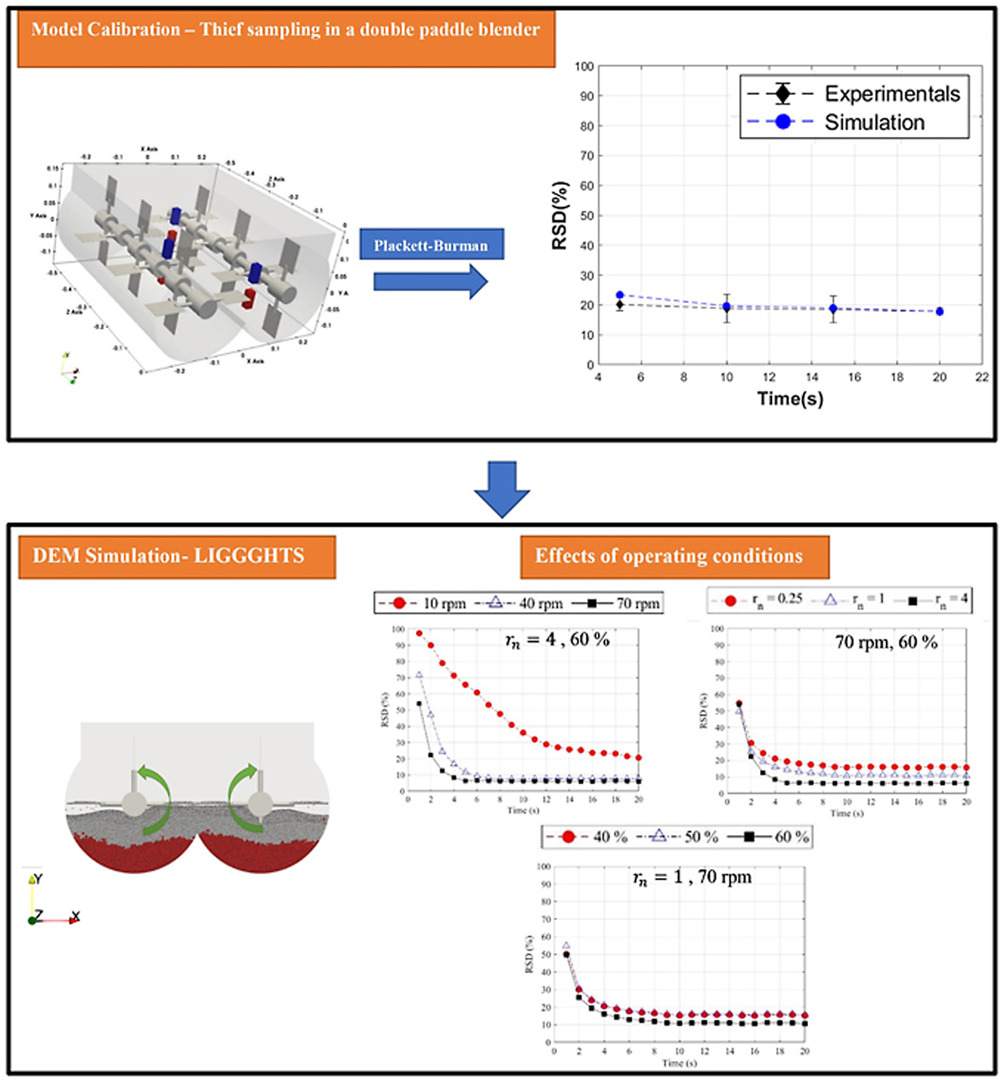

• The blending of bi-disperse particles in a double paddle blender was examined.

• DEM parameters were calibrated using Plackett-Burman design experiment method.

• The effect of various operating parameters on mixing quality was investigated.

• Paddle speed and particle number ratio significantly affected the mixing quality.

• Diffusion was the dominant mixing mechanism in the double paddle blender.

A double paddle blender's flow patterns and mixing mechanisms were analyzed using discrete element method (DEM) and experiments. The mixing performance of this type of the blender containing bi-disperse particles has been rarely studied in the literature. Plackett-Burman design of experiments (DoE) methodology was used to calibrate the DEM input parameters. Subsequently, the impact of the particle number ratio, vessel fill level, and paddle rotational speed on mixing performance was investigated using the calibrated DEM model. The mixing performance was assessed using relative standard deviation and segregation intensity. Mixing performance was significantly affected by the paddle rotational speed and particle number ratio. Moreover, the Peclet number and diffusivity coefficient were used to evaluate the mixing mechanism in the blender. Results revealed that the diffusion was the predominant mixing mechanism, and the best mixing performance was observed when the diffusivity coefficients of 3 mm and 5 mm particles were almost equal.