- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

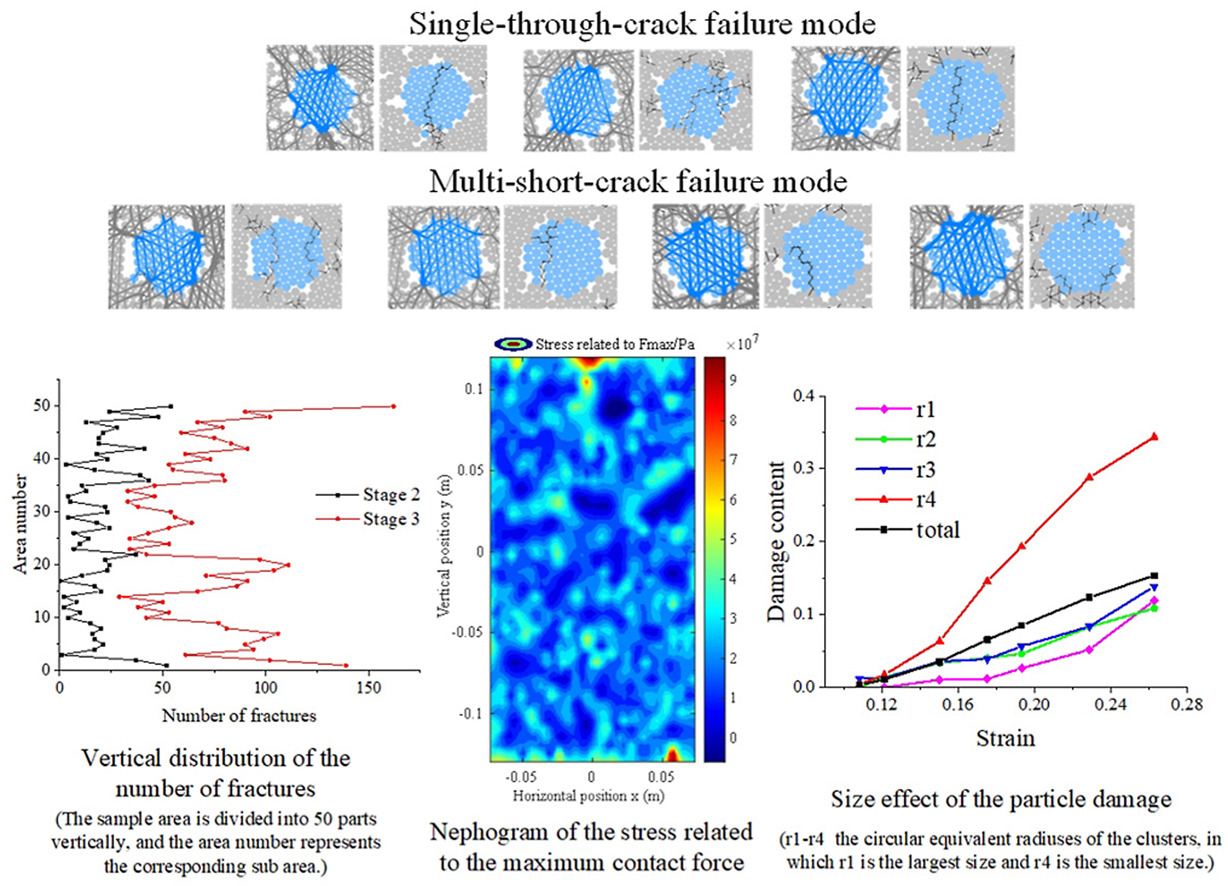

• Evolution law of contact and contact force during the loading process is revealed.

• Two particle failure modes caused by different contact force states are presented.

• Stress based on maximum contact force and major principal stress can better reflect distribution of cracks.

• Relationship between size effect of particle breakage and lateral pressure coefficient is demonstrated.

In order to study the fragmentation law, the confined compression experiment of granular assemblies has been conducted to explore the particle breakage characteristic by DEM approach in this work. It is shown that contact and contact force during the loading process gradually transform from anisotropy to isotropy. Meanwhile, two particle failure modes caused by different contact force states are analyzed, which are single-through-crack failure and multi-short-crack failure. Considering the vertical distribution of the number of cracks and the four characteristic stress distributions (the stress related to the maximum contact force, the major principal stress, the deviatoric stress and the mean stress), it is pointed out that the stress based on the maximum contact force and the major principal stress can reflect the distribution of cracks accurately. In addition, the size effect of particle crushing indicates that small size particles are prone to break. The lateral pressure coefficient of four size particles during the loading process is analyzed to explain the reason for the size effect of particle breakage.