- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

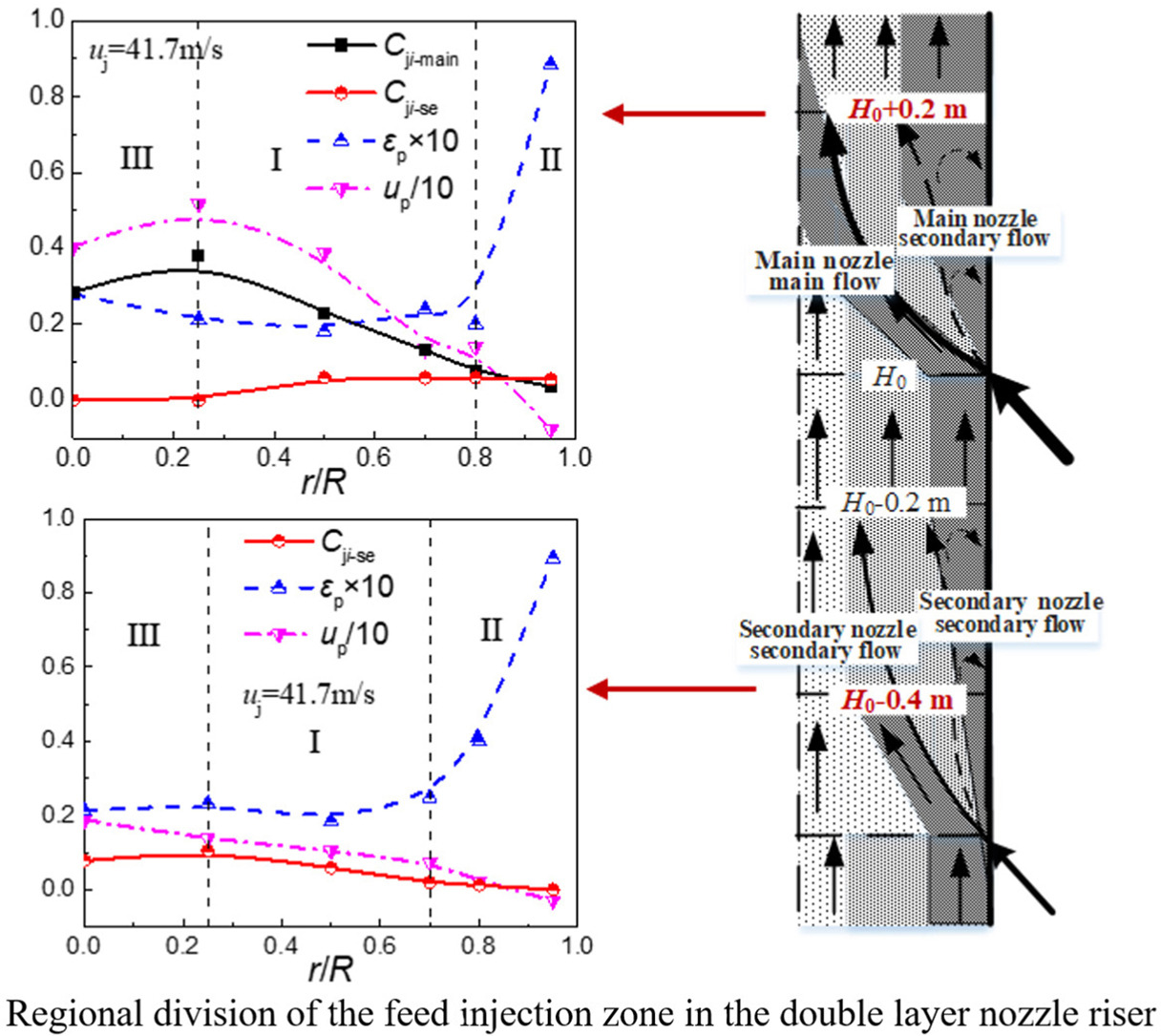

• The double-level nozzle riser is experimentally investigated.

• The injection zone is divided into the upstream flow, main flow and secondary flow control regions.

• Secondary nozzle jet gas presents a poor match to particles below the main nozzle.

• Secondary nozzle jet gas can improve the oil-catalyst match near the wall.

• Secondary nozzle jet gas can avoid the coking above the main nozzle.

With the development of current energy economy, it is necessary to improve the product distribution of fluid catalytic cracking process, which is achieved by a riser reactor with double-level of nozzles. The new riser is constructed by adding a level of secondary nozzle 0.5 m below the main nozzle of traditional riser. This paper investigates the gas-solids flow and oil-catalyst matching feature based on the optical fiber and tracer technologies. According to the distribution of solids holdup, particle velocity and dimensionless jet concentration, the feedstock injection zone can be divided into the upstream flow control region, the main flow control region, and the secondary flow control region in the radial direction. The size of the regions is changed by the jet gas velocity and axial height. There is a poor match of secondary nozzle jet to particles below the main nozzle. The jet gas from secondary nozzles can improve the matching effect of oil-catalyst near the wall and reduce the probability of coking above the main nozzle.