- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

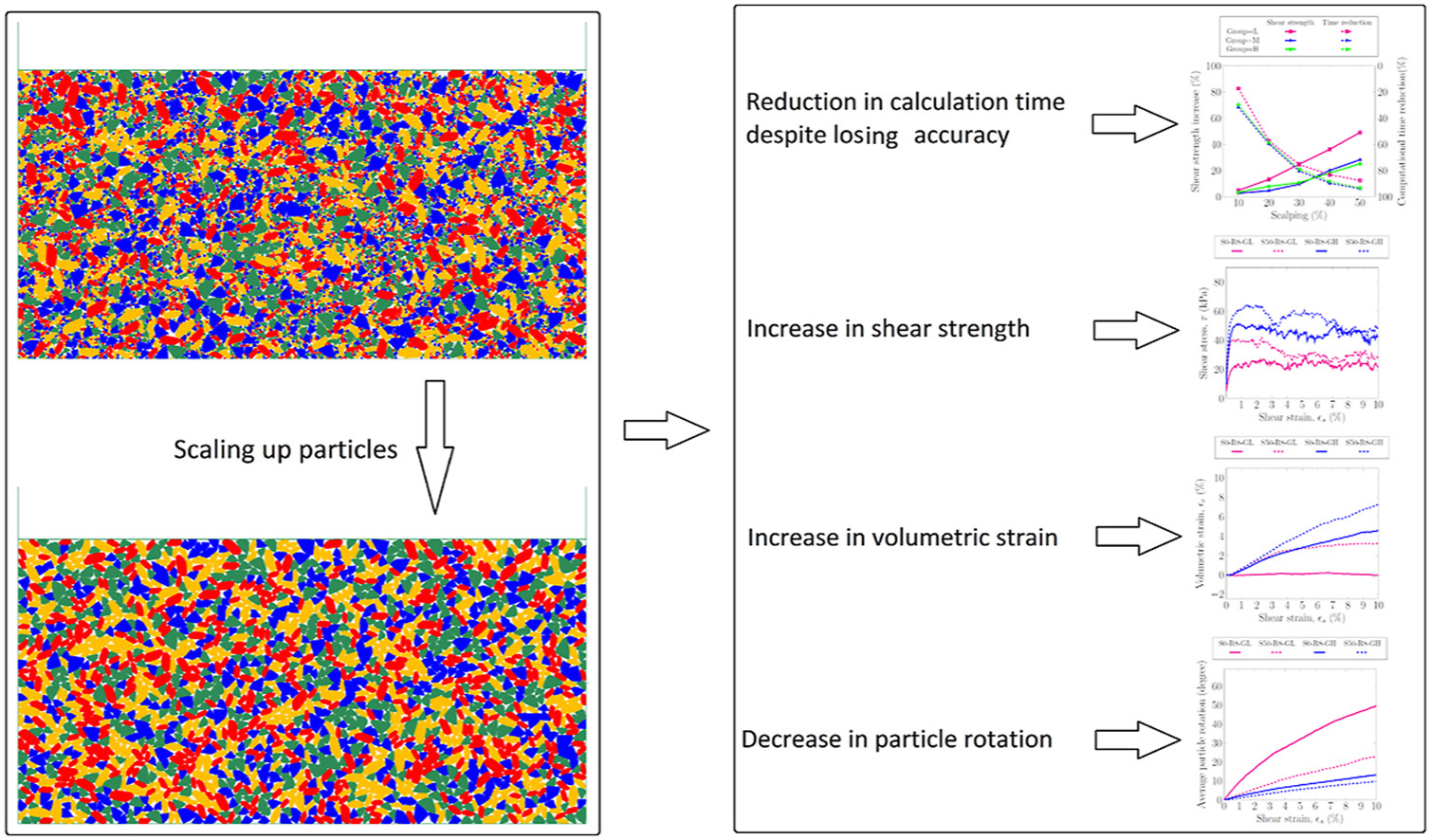

• The scalping method can simulate the correct shear behavior of granular material.

• The scalping method improves computational time dramatically despite some loss of accuracy in predicted values.

• Particle size distribution has a significant effect on effectiveness of particle scalping.

• Particle angularity and rotation affect the accuracy of the scalping method.

Despite advancements in computational resources, the discrete element method (DEM) still requires considerable computational time to solve detailed problems, especially when it comes to the large-scale models. In addition to the geometry scale of the problem, the particle shape has a dramatic effect on the computational cost of DEM. Therefore, many studies have been performed with simplified spherical particles or clumps. Particle scaling is an approach to increase the particle size to reduce the number of particles in the DEM. Although several particle scaling methods have been introduced, there are still some disagreements regarding their applicability to certain aspects of problems. In this study, the effect of particle scalping on the shear behavior of granular material is explored. Real granular particles were scanned and imported as polygonal particles in the direct shear test. The effect of particle size distribution, particle angularity, and the amount of scalping were investigated. The results show that particle scalping can simulate the correct shear behavior of the model with significant improvement in computational time. Also, the accuracy of the scalping method depends on the particle angularity and particle size range.