- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

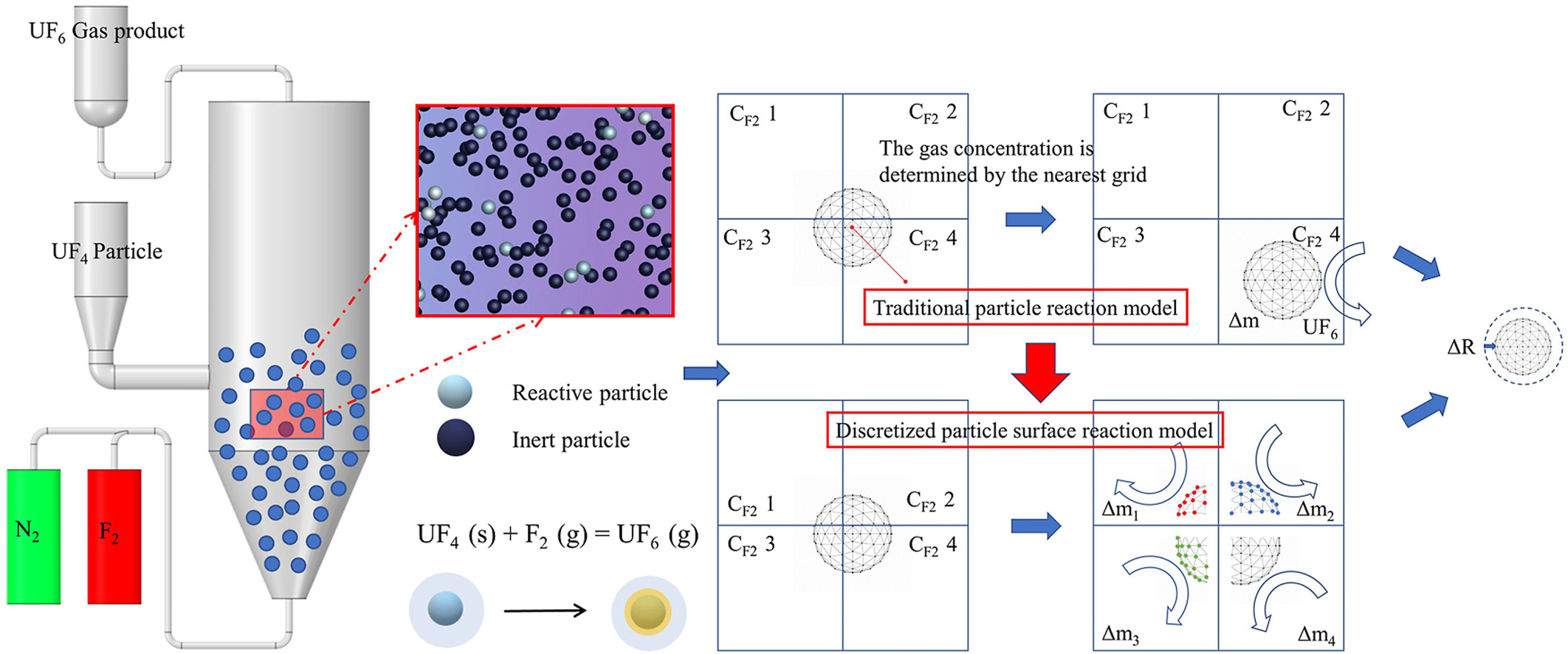

• Coupling model based on CFD-DEM was established to simulate UF4 fluoridation.

• Discretized particle shrinking model was proposed and validated.

• Multistage conical fluidized bed was designed to extended the application range.

• Effects of operating parameters related to industrial production were discussed.

A CFD-DEM reaction coupling model was established to simulate UF4 fluorination process, in which heat and mass transfer, heterogeneous chemical reaction, and particle shrinkage model were considered. The gas behavior was described by the conservation laws of mass, momentum, and energy. The solid phase is modeled with the discrete element method, considering the gas–solid interphase force, contact force, heat transfer, and chemical reaction models based on the discretized surface. Each particle can be individually tracked and associated with specific physical properties. The proposed CFD-DEM reaction coupling model based on particle shrinking reaction model with discretized surface was validated by the experimental and literature results at first. Then a multistage conical spouted bed was proposed and the process of UF4 fluoridation reaction in it was investigated. The fluidization characteristics and the concentration distribution of gaseous products in the spouted bed with an extended gas velocity range were obtained and analyzed. In addition, the effects of different parameters, such as superficial gas velocity, temperature, fluorine concentration, on fluoridation rate and the fluorine conversion rate were investigated based on the proposed CFD-DEM reaction coupling model. The results obtained in this work are beneficial for method development of the chemical reaction simulation research in particle scale using the CFD-DEM model, and useful for operation and equipment parameters design of the uranium tetrafluoride fluorinate industrial process in the future.