- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

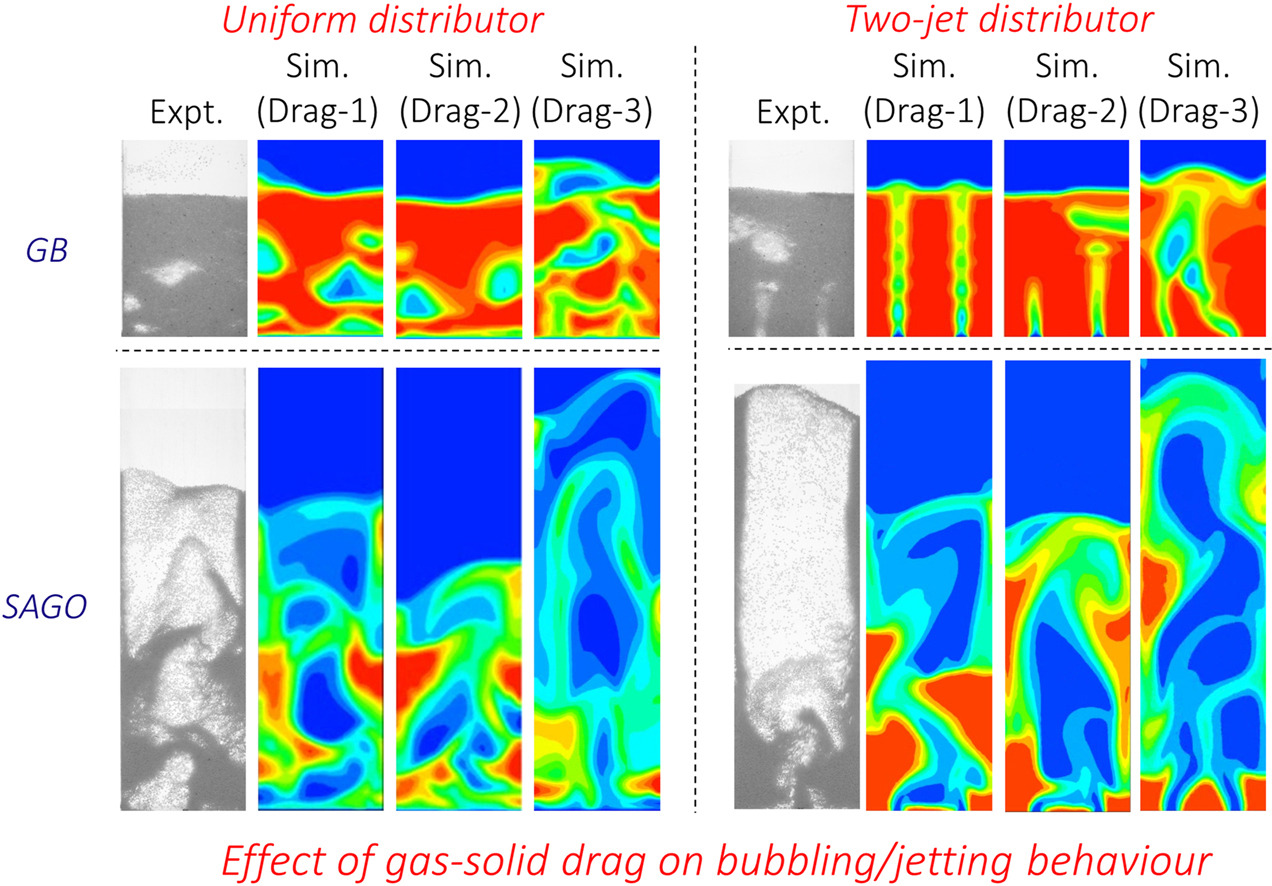

• Bubbling and jetting behavior characterized using high-speed imaging measurements and Eulerian simulations.

• Increase in frictional viscosity decreased bubble rise velocity and size.

• Significant variation in jetting behavior predicted using different gas–solid drag models.

• EMMS-based drag model correctly predicts jetting behavior under dilute flow conditions.

• Analysed effects of gas distributor, particle density, and gas velocity on bubbling and jetting behavior.

The mode of gas-injection is known to influence the local bubbling and jetting behavior in gas–solid fluidized beds. The resultant bubbling behavior influences the mixing and distribution of the gas and solid phases, which in turn can influence heat and mass transfer, and reaction performance in large-scale gas–solid fluidized beds. In the present work, we simulated unary gas–solid flow of particles differing in density, fluidized using uniform and two-jet distributors at different UG. The predictions are validated using the measured local gas-phase area fraction fluctuations, bubble size distribution, and bubble rise velocity. The effect of the models used for calculation of gas–solid drag (βgs), solids frictional pressure (Ps,f), and specularity coefficient (φ) on the bubbling characteristics under dense and dilute flow conditions are analysed. Under dense bed condition (UG = 1.1 Umf), an increase in the Ps,f and φ led to an increase in solids viscosity, which in turn led to a decrease in the bubble rise velocity and size. In the case of the two-jet distributor, an increase in βgs predicted merging of the larger jets and formation of larger bubbles. Further, to predict the different jetting regimes (isolated jets, breakage/merging of jets, and generation of larger bubbles) at different UG correctly, we show that different βgs models are required. Whereas, in the case of gas–solid flows comprised of particles of different density fluidized with the uniform distributor, a single βgs model predicted the bubbling characteristics reasonably well with measurements.