- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Review of gas–liquid injection into gas–solid fluidized beds.

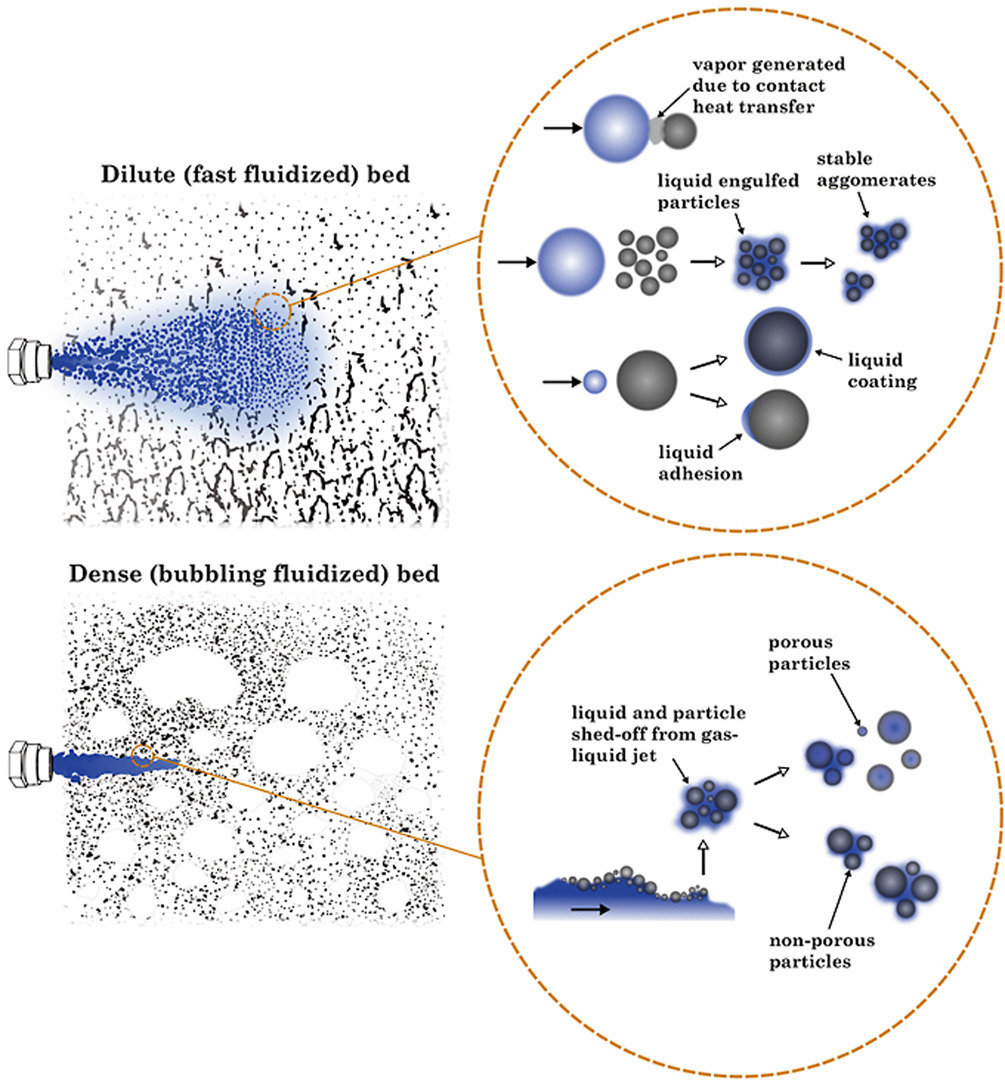

• The relevant physics of gas–liquid injection mechanism depends on the bed voidage.

• In dilute beds, liquid feed atomization results in a spray of droplets.

• In dense beds, atomization is suppressed and a jet cavity of liquid is encountered.

• Wet particle agglomeration and particle porosity should be included in CFD models.

Injection of gas–liquid sprays into gas–solid fluidized beds finds application in many industries. Effective mixing and distribution of liquid feed and solid bed material is paramount to ensure an efficient and profitable process. Despite its long-term use, the mechanism of liquid injection into gas–solid fluidized beds continues to raise questions and is only partially understood. This paper provides a thorough and up-to-date review of experimental and numerical investigations of gas–liquid sprays into gas–solid fluidized beds conducted over the past decades. Based on the surveyed literature, a phenomenological description of the prevalent mechanisms of gas–liquid injection under different operating conditions is presented. This review identifies suitable computational fluid dynamic models for simulating the mechanisms involved in gas–liquid–solid interactions along with recommendations for future numerical and experimental work.