- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

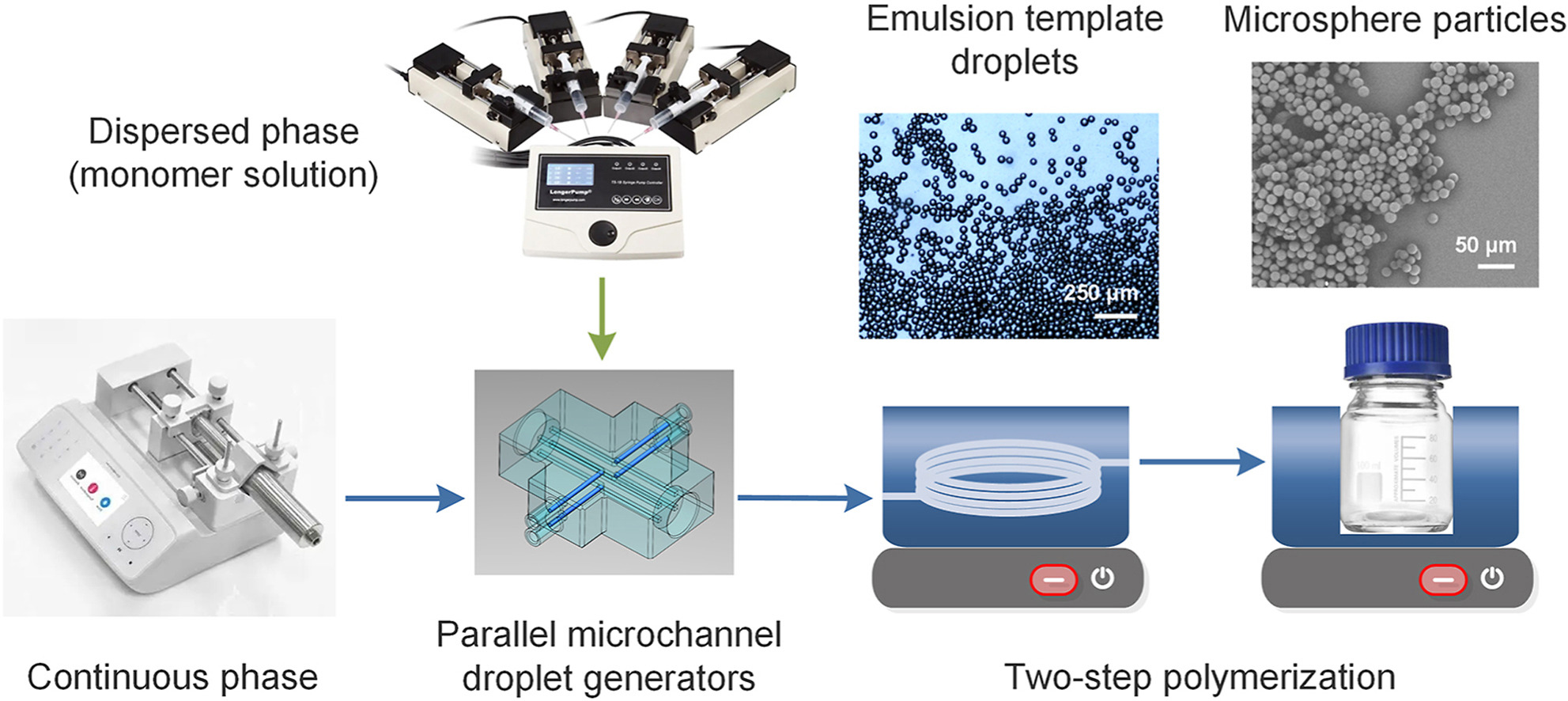

• A flow rate deviation robust droplet generator was parallel scaled-up via 3D-print fabrication.

• Jetting flow was employed to increase the droplet generation efficiency in the microchannel.

• 2.8 × 104 Hz high generation frequency of droplets was achieved using only 4 droplet generators.

• 32–52 μm droplets with 4.5%–8.4% diameter variation coefficients were high-throughput created.

• 16.9–23.5 μm particles with 5.0%–8.6% diameter variation coefficients were prepared on hundred mg/hour.

To prepare uniform polystyrene particles with ten microns of diameter, a parallel scaling-up strategy for the capillary-assembled stepwise microchannel was developed, which created uniform droplets with high-throughput and formed a large amount of emulsion templates for the polymerization of styrene and cross-linker. The microchannel droplet generator was robust for the flow rate deviation of the continuous phase in the jetting flow, and droplet generation frequency up to 2.8 × 104 Hz was achieved with only four parallel droplet generators, which were much more efficient than the parallelly scaled microfluidic devices working in dripping flow. 32–52 μm average diameter droplets with 4.5%–8.4% diameter variation coefficients were successfully prepared from the microchannel device fabricated by low-cost 3D-print method, and the droplets were subsequently turned to solid particles via a two-step polymerization in the platform. The polystyrene particles were further reduced to 16.9–23.5 μm with 5.0%–8.6% diameter variation coefficients due to the accompanying emulsion polymerization, and the working capacity of the platform reached hundred milligrams of particles per hour.