- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

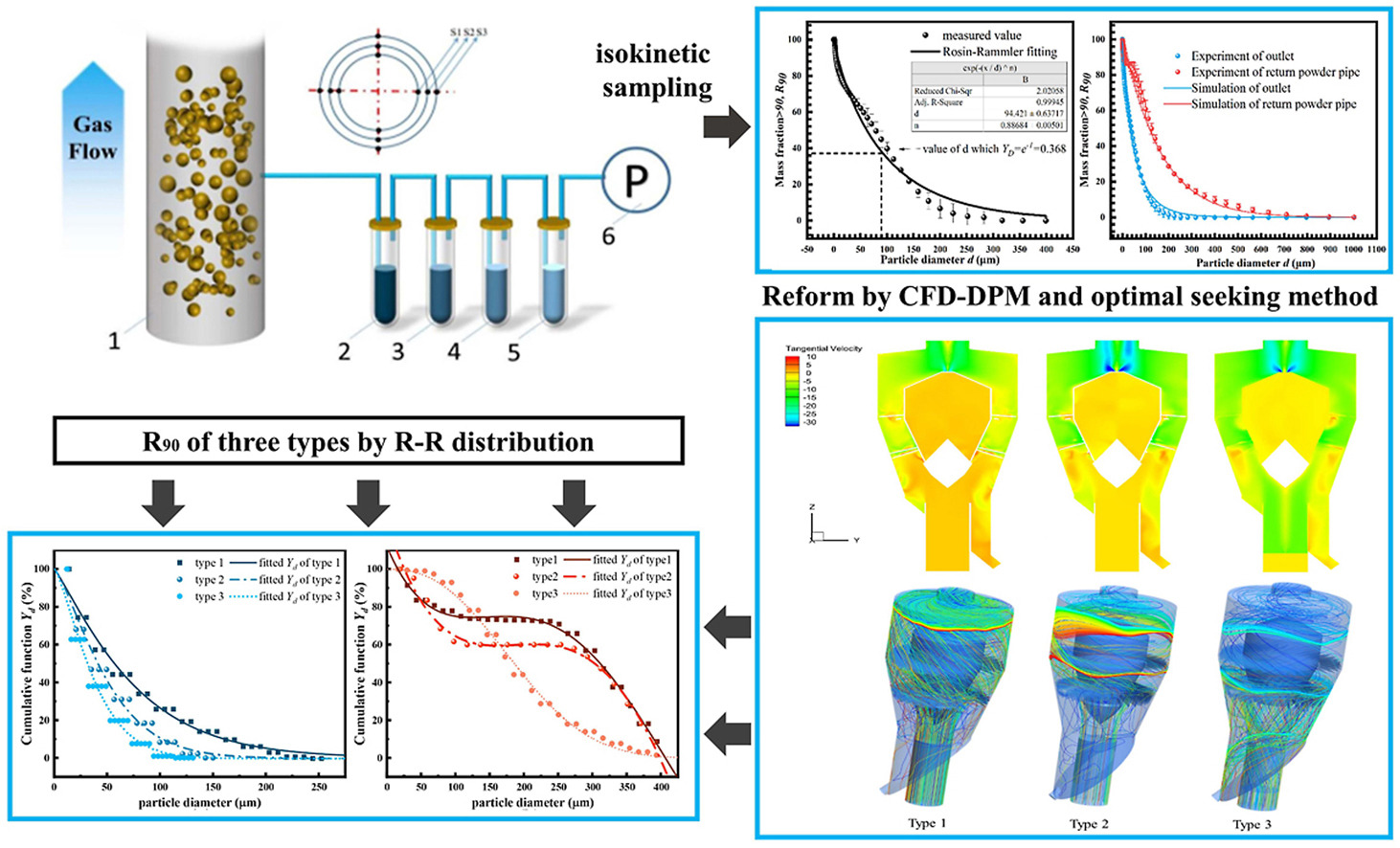

As a major equipment for thermal power plants, the main function of coarse powder separators is to separate particles into size groups according to particle diameter. With the rising coal prices, power plants are using more low-density lignite. Consequently, the original equipment does not operate under normal conditions. Therefore, to return the equipment to normal operating conditions, the isokinetic sampling method, computational fluid dynamics (CFD), and discrete phase model (DPM) based on the Euler–Lagrange method are applied in this research to analyze the effect of baffle shapes, baffle numbers, and centrifugal blades on the equipment performance index, like R90. The shape of the baffle plate was optimized and improved. Preferential method was applied to determine the optimal number of baffles to ensure normal working conditions. Results show that curved baffles can suppress the axial negative gradient field below themselves better than rectangular baffles. The curved baffles selected by the optimal seeking method make full use of the negative axial gradient field and provide the particles entering the separation zone at tangential velocity in advance with the addition of centrifugal blades. Thus, pre-separation can be realized. The R90 is 5 at the separator outlet and 95 at the powder return port, indicating that the output capacity of the separator returned to a reasonable operating performance.