- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

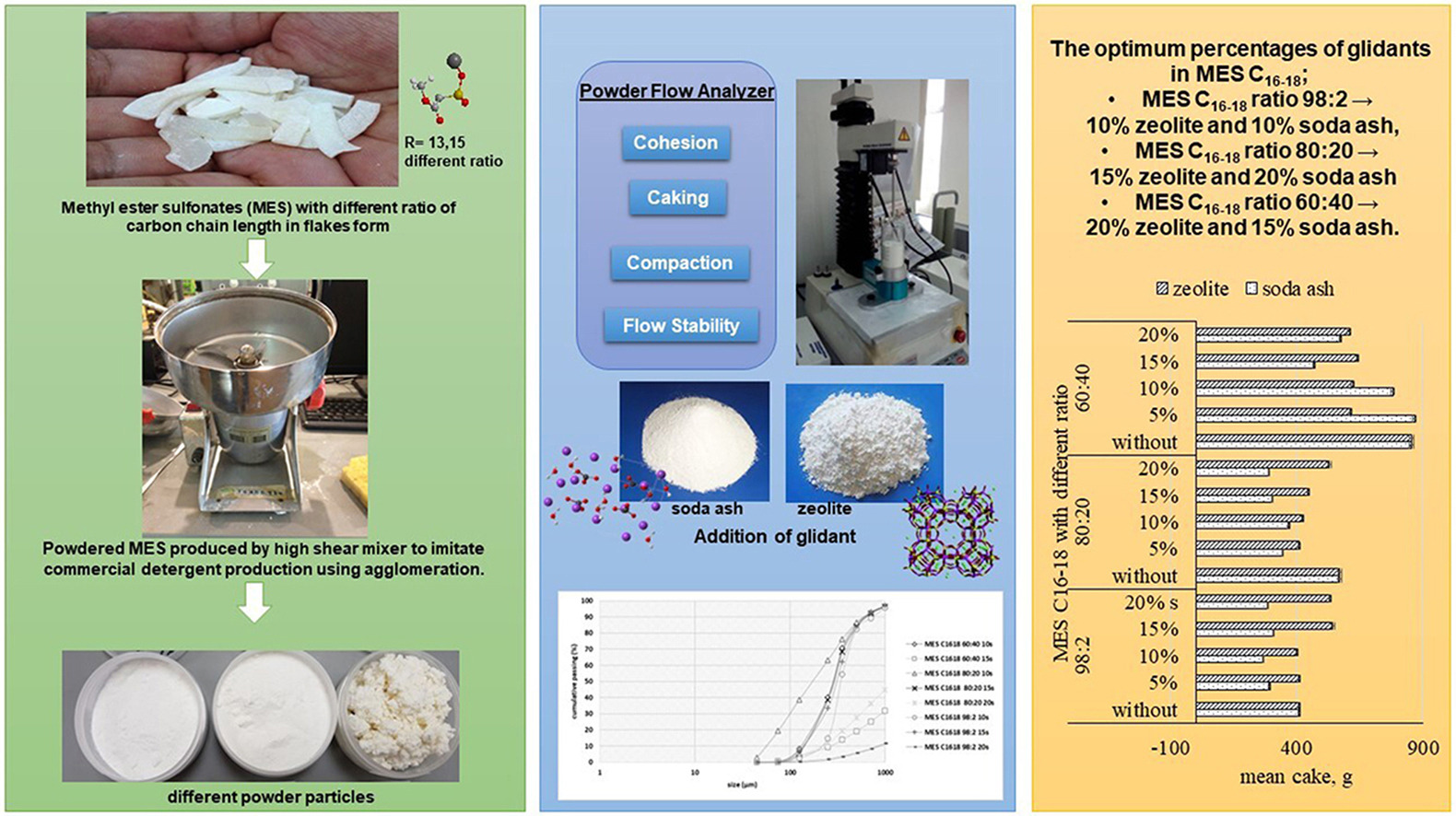

• Preparation of various ratio C16-18 powder methyl ester sulfonates (MES) via high shear mixer.

• Powder MES behavior on morphology, size, cohesion, caking, and compaction has been studied.

• The higher amount of C18 in MES influenced the behavior of powder.

• Certain amount of zeolite/soda ash was required for different ratio of C16-18 MES powder.

The preparation and behavior of powder stearin-based methyl ester sulfonates (MES) with the addition of builder as a glidant agent was studied. MES is an anionic surfactant and its performance is equivalent to petroleum-based linear alkylbenzene sulfonates (LAS), the workhorses of the detergent industry. At the same time, zeolites or soda ash were the alternative builders for non-phosphate-based detergent. The behavior of powder MES properties was measured in terms of morphology, particle size, cohesion, caking, and compaction. Before that, these palm stearin-based MES of carbon chain 16–18 with ratios of 98:2, 80:20, and 60:40 in flakes were ground using a high shear mixer by 23,000 rpm to produce powder particles. Decreasing the particle size of MES powder can reduce the powder's cohesion, caking, and compaction. The addition of zeolite or soda ash as a glidant in powdered MES can improve the caking behavior. The high stearic in MES greatly influenced getting fine particle powders and required more glidant agents. This powder MES with excellent powder characteristics can perform well as a bio-based cleaning product.