- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

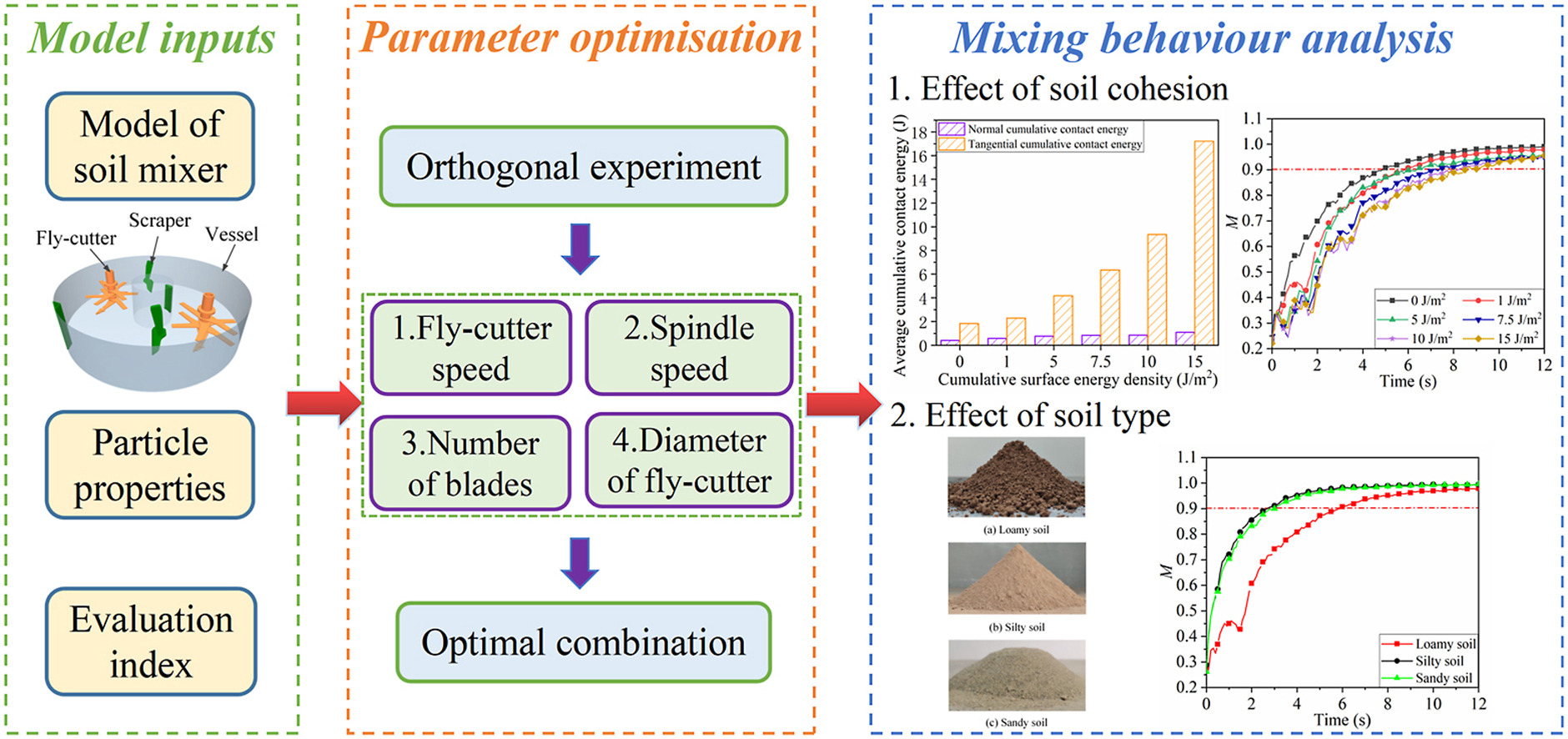

• Orthogonal experiment and comprehensive scoring methods were carried out to find out the optimal parameter combination.

• Mixing rate of the material becomes slower and the “shaft hugging” becomes serious as soil cohesion increases.

• The wear and tear of the soil mixer increased with the increase of soil cohesion.

• The radial and tangential velocities of three soils showed a pattern of periodic oscillations.

Soil mixing is an emerging research in the field of construction resource recovery. In this study, the mixing behaviour of soil particles in a mixer is numerically simulated by the discrete element method (DEM). A four-factor, three-level orthogonal experiment is designed to optimize the mixer design by selecting the fly-cutter speed, spindle speed, number of blades and fly-cutter diameter, using Lacey mixing index and power consumption as evaluation indicators. Then, the impact of soil cohesion and type on the mixing behaviour is investigated. The results show that the optimal parameter combination of this experiment is 280 rpm fly-cutter speed, 40 rpm spindle speed, 4 blades and 250 mm fly-cutter diameter. This optimal combination reaches a comparatively uniform state mix in 5.9 s with an average power consumption of 704.11 W. In addition, the wear and tear of the mixer increases as soil cohesion increases, while the mixing quality of materials declines, resulting in a “shaft hugging” phenomenon. The mixing efficiency varies greatly among different soil types, but the radial and tangential velocities have a similar law. This work can provide some guidance for the optimization design of a mixer and study of soil mixing.