- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• A CPFD model is established to further tap the NOx abatement potential of CFB boilers.

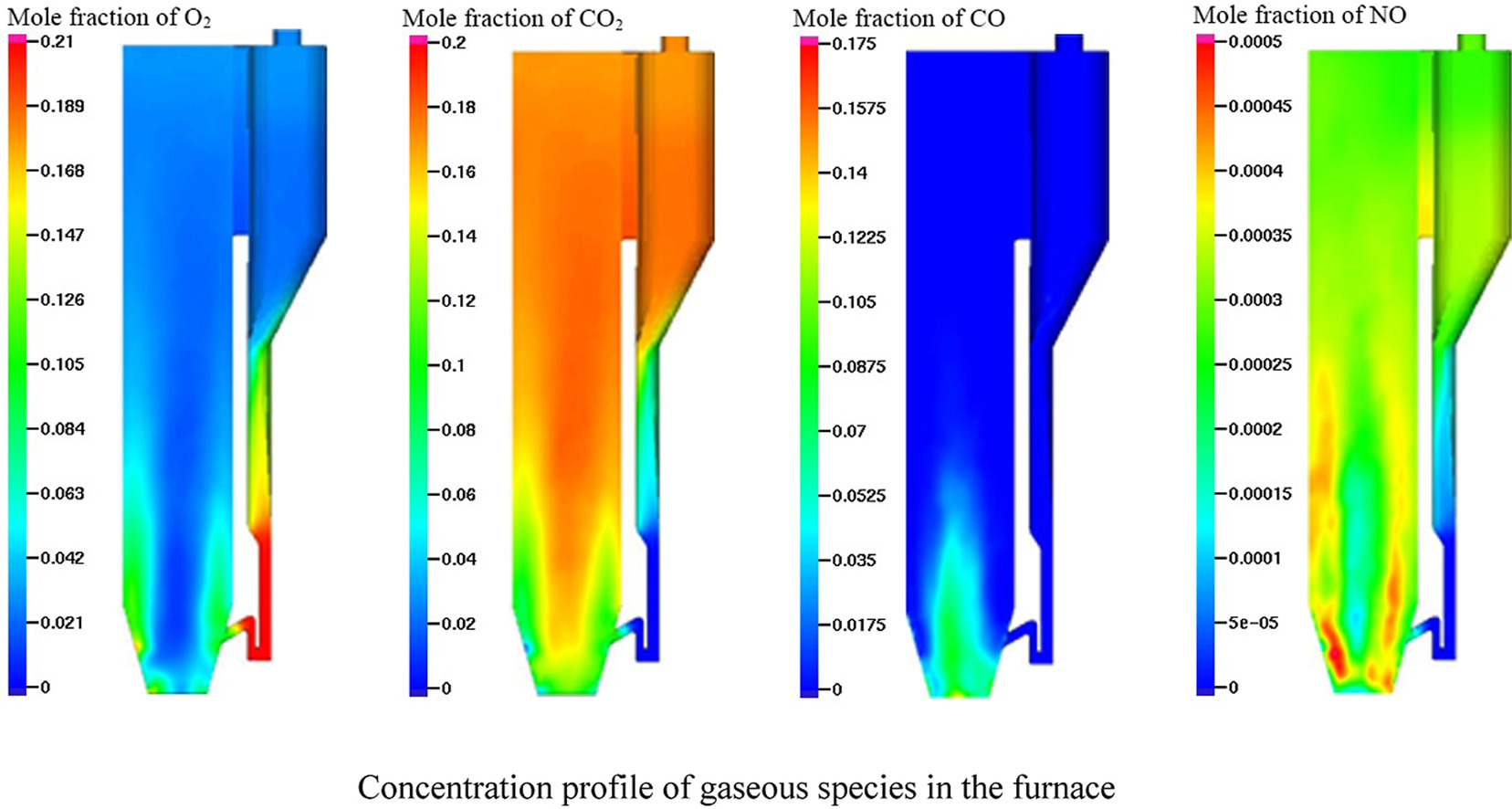

• Oxygen-deficient combustion results in high CO and NOx contents in the bottom furnace.

• Intensifying/making full use of in-furnace reducing atmosphere helps to reduce NO emission.

• Appropriate reducing primary air and coal particle size favors for lower NOx emission.

The ultra-low NOx emission requirement (50 mg/m3) brings great challenge to CFB boilers in China. To further tap the NOx abatement potential, full understanding the fundamentals behind CFB boilers is needed. To achieve this, a comprehensive CPFD model is established and verified; gas-solid flow, combustion, and NOx emission behavior in an industrial CFB boiler are elaborated; influences of primary air volume and coal particle size on furnace performance are evaluated. Simulation results indicate that there exists a typical core-annular flow structure in the boiler furnace. Furnace temperature is highest in the bottom dense-phase zone (about 950 °C) and decreases gradually along the furnace height. Oxygen-deficient combustion results in high CO concentration and strong reducing atmosphere in the lower furnace. NOx concentration gradually increases in the bottom furnace, reaches maximum at the elevation of secondary air inlet, and then decreases slightly in the upper furnace. Appropriate decreasing the primary air volume and coal particle size would increase the CO concentration and intensify the in-furnace reducing atmosphere, which favors for NOx reduction and low NOx emission from CFB boilers.