- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

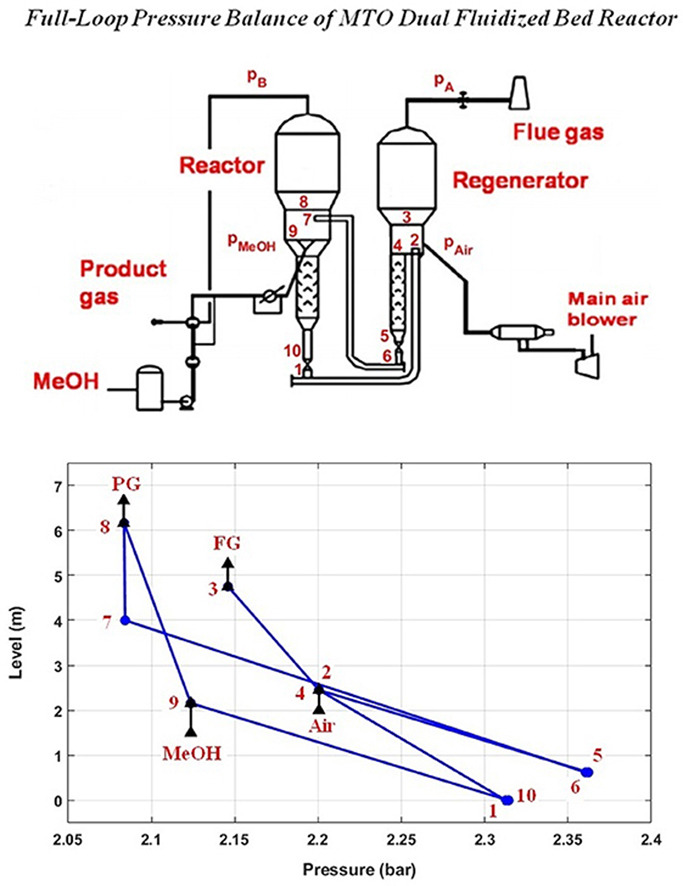

• Full-loop pressure balance analysis was performed on methanol-to-olefins (MTO) dual fluidized bed reactor.

• MTO dual fluidized bed reactor model was coupled with overall pressure balance.

• Geometric dimensions of a demo-scale reactor configuration were determined.

• Catalyst mass distribution was calculated throughout the entire system.

• This analysis provides the basis for CFD, scale-up and process optimization studies.

Development of a comprehensive reactor model is of paramount importance for design and scale-up of methanol-to-olefins (MTO) process in a dual fluidized bed reactor (DFB). These models must integrate suitable reaction kinetic expressions with hydrodynamic models properly descriptive of gas-solid contact in fluidized bed reactors. In this modeling study, our previously developed kinetic models of MTO fluidized bed reactor and regenerator are coupled with overall mass, energy and pressure balances to ensure smooth circulation of catalyst particles between the two fluidized beds. This integrated model was then applied to determine geometric dimensions of a demo-scale MTO DFB configuration and to obtain the mass distribution of catalyst particles throughout the entire system including the pipes connecting the two reactors. Our model is capable of being integrated into simulation software such as Aspen Plus for plant-wide optimization and scale-up studies.