- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

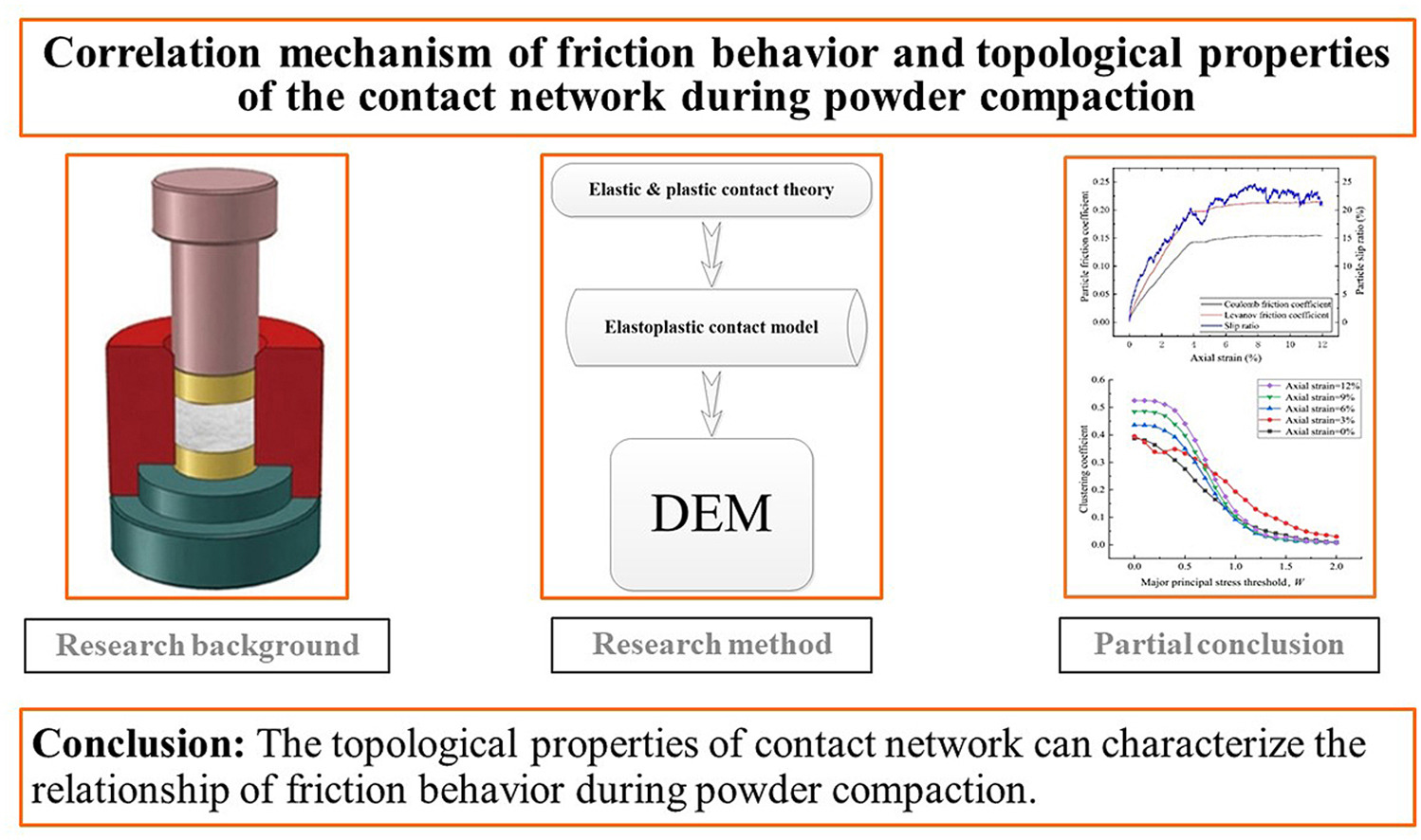

• Based on die powder compaction, an elastic-plastic contact model is developed for metal powder compaction.

• Elastic-plastic contact model used is more reasonable than the widely used Hertz elastic contact model.

• Topological properties of contact network can characterize the relationship of friction behavior during powder compaction.

• Due to frictional behavior, topological properties of contact network have different manifestations in different regions.

The effect of friction behavior on the compacted density is significant, but the relationship between the topological properties of the contact network and friction behavior during powder compaction remains unclear. Based on the discrete element method (DEM), a DEM model for die compaction was established, and the Hertz contact model was modified into an elastoplastic contact model that was more suitable for metal-powder compaction. The evolution of the topological properties of the contact network and its mechanism during powder compaction was explored using the elastoplastic contact model. The results demonstrate that the friction behavior between the particles is closely related to the topological properties of the contact network. Side wall friction results in smaller clustering coefficient (CC) and excess contact (EC) in the lower region near the side wall. Corresponding to this phenomenon, the upper region near the side wall has more high-stress particles when the major principal stress threshold was considered, and the CC and EC are significantly higher than those in the other regions. This study provides a theoretical basis for improving powder compaction behavior.