- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

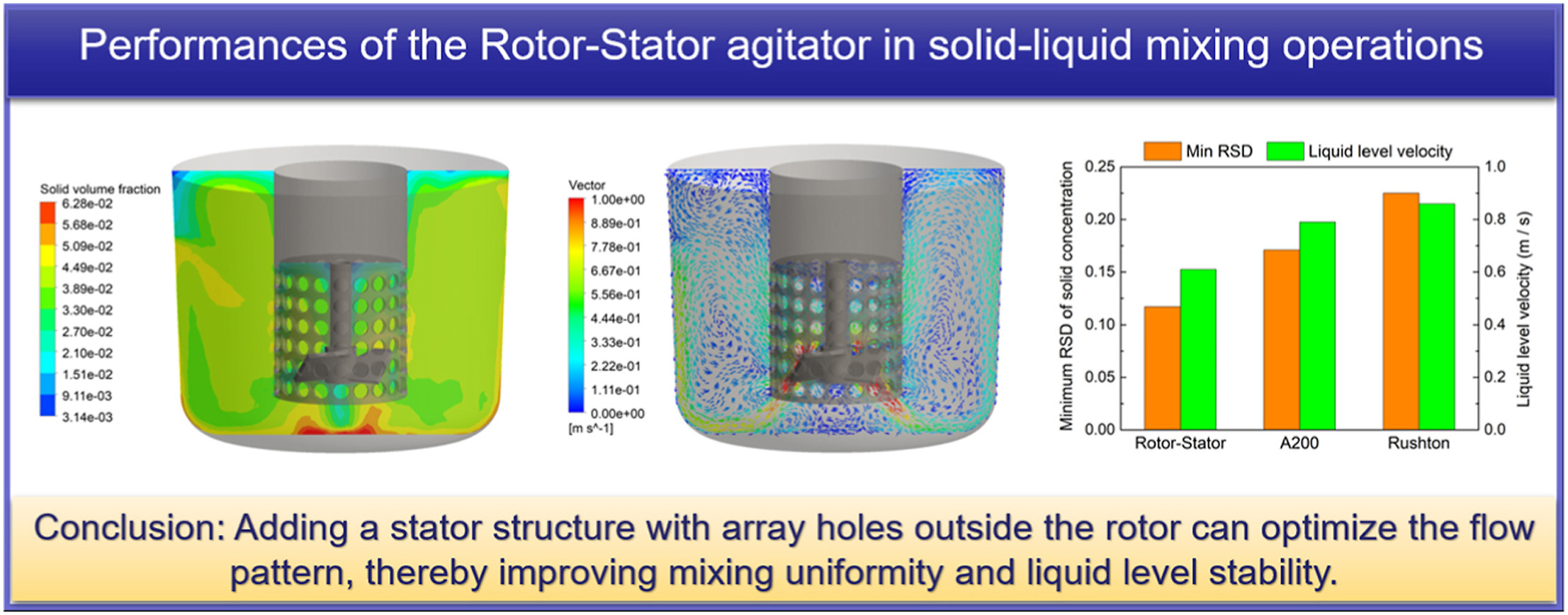

• Stator structure improves flow pattern, homogeneity and liquid level stability.

• The Rotor-Stator agitator was more effective than Rushton and A200 agitators.

• There exists an optimal stirring speed in solid-liquid mixing process.

• Decreasing particle size can improve the homogeneity.

• Increasing solid loading can improve the homogeneity at high stirring speeds.

The solid-liquid mixing is an important operation unit in the preparation of composites by stirring casting. High quality composite materials need good homogeneity and stable liquid level. In this work, the performances of the Rotor-Stator agitator for solid suspension in stirred tank were investigated through CFD modeling, including the homogeneity, power consumption and liquid level stability. The Eulerian-Eulerian (E-E) multiphase model and the RNG k-ε turbulence model were adopted for modeling the multiphase flow and the turbulence effects, respectively. The effect of various important parameters such as stirring speed, particle size, solid loading and the use of baffles were examined. Adding a stator structure with array holes outside the rotor can optimize the flow pattern, thereby improving the mixing uniformity and liquid level stability. The homogeneity and liquid level stability attained by the Rotor-Stator agitator were better than those for the A200 (an axial-flow agitator) and the Rushton (a radial-flow agitator).