- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

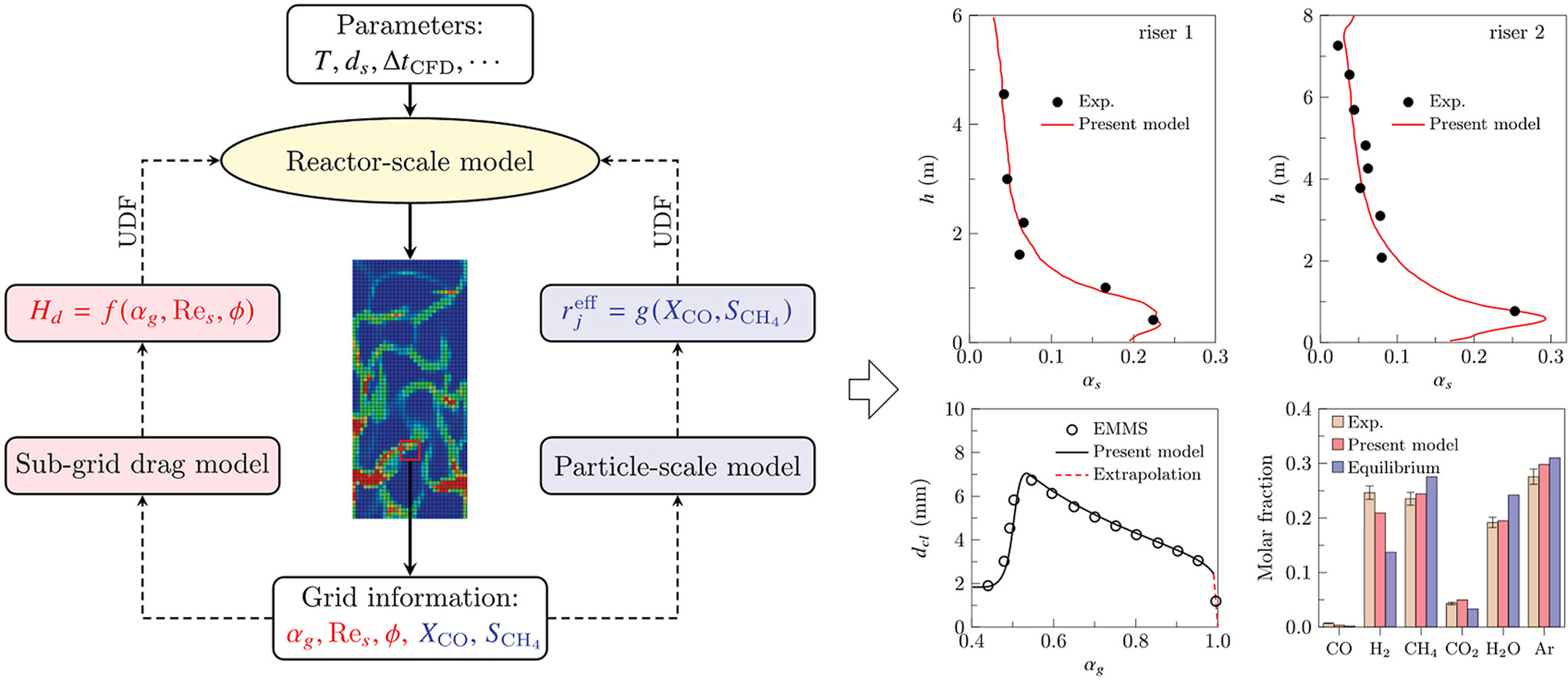

• Particle-scale model reveals the transient diffusion and reactions inside the catalysts.

• Sub-grid drag model considers the effects of the meso-scale and chemical reactions.

• Strategy for coupling the particle-scale and sub-grid drag models into CFD is proposed.

• The coupled model can predict accurate gas-solid flow and chemical reactions in a riser.

• The coupled model allows coarse grid and large time step size to accelerate the simulations.

The diffusion and chemical reactions inside the catalyst particles and the heterogeneous flow structure in the computational cells are key factors to affect the accuracy of the coarse-grid simulation in circulating fluidized bed (CFB) methanation reactors. In this work, a particle-scale model is developed to calculate the effective reaction rate considering the transient diffusion and chemical reactions in the particle scale, i.e., the scale of the single catalyst particle. A modified sub-grid drag model is proposed to consider the effects of the meso-scale and chemical reactions on the heterogeneous gas-solid interaction, where the meso-scale is between the single particle and the whole reactor and featured with the particle cluster. Subsequently, a coupled model is developed by integrating the particle-scale and modified sub-grid drag models into CFD. Moreover, the coupled model is validated to achieve accurate predictions on the CO methanation process in a CFB riser. Notably, the coupled model can be performed with a coarse grid (∼58 times particle diameter) and a large time step (0.005 s) to accelerate the simulation. By simply changing the reaction kinetics, different gas-solid catalytic reaction systems can be simulated by using the coupled model.