- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

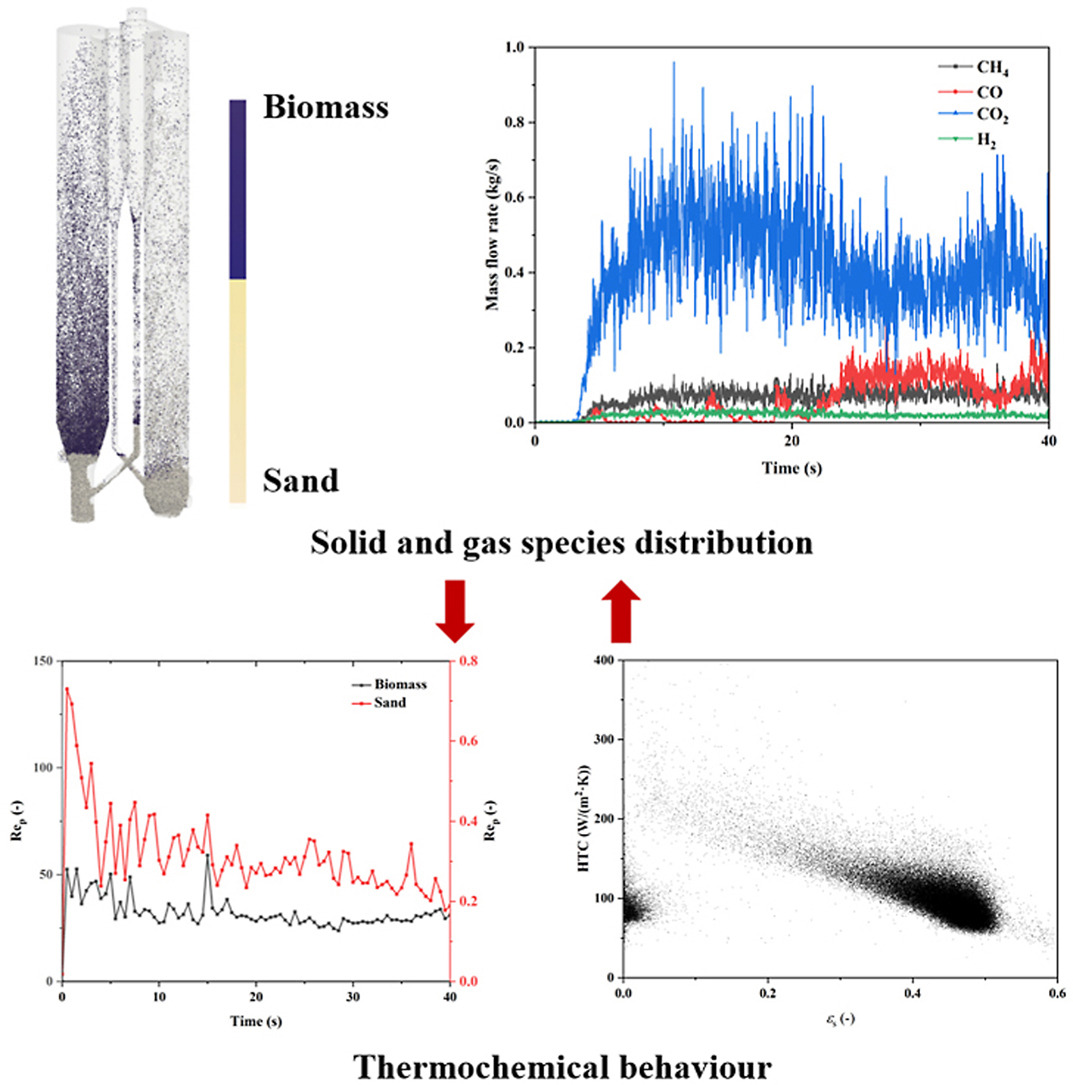

• Biomass gasification in an industrial-scale dual circulating fluidized bed was studied.

• Size-/density-induced segregation makes solid fuels concentrate on the bed surface.

• Temperature in the combustor is about 100 K higher than that in the gasifier.

• HTCs are 50–150 W/(m2 K) in the combustor and 100–200 W/(m2 K) in the gasifier.

• Reynolds number of biomass particles is two orders of magnitude larger than sand particles.

Dual circulating fluidized bed (DCFB) has emerged as an efficient reactor for biomass gasification due to its unique feature of high gas-solid contact efficiency and separated reactions in two reactors, yet the understanding of complex in-furnace phenomena is still lacking. In this study, biomass gasification in an industrial-scale DCFB system was numerically studied using a multiphase particle-in-cell (MP-PIC) method featuring thermochemical sub-models (e.g., heat transfer, heterogeneous reactions, and homogeneous reactions) under the Eulerian-Lagrangian framework. After model validation, the hydrodynamics and thermochemical characteristics (i.e., pressure, temperature, and species) in the DCFB are comprehensively investigated. The results show that size-/density-induced segregation makes solid fuels concentrate on the bed surface. Interphase momentum exchange leads to the continuous decrease of the gas pressure axially. In the gasifier and combustor, the lower heating value (LHV) of the gas products is 5.56 MJ/Nm3 and 0.2 MJ/Nm3 and the combustible gas concentration (CGC) is 65.5% and 1.86%, respectively. The temperature in the combustor is about 100 K higher than that in the gasifier. A higher solid concentration results in a smaller value of particle heat transfer coefficient (HTC). The HTCs range from 50 to 150 W/(m2 K) for a solid concentration larger than 0.3 in the combustor while the HTCs range from 100 to 200 W/(m2 K) in the gasifier. The Reynolds number of biomass particles is two orders of magnitude larger than that of the sand particle. The numerical results shed light on the reactor design and process optimization of biomass gasification in DCFBs.