- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

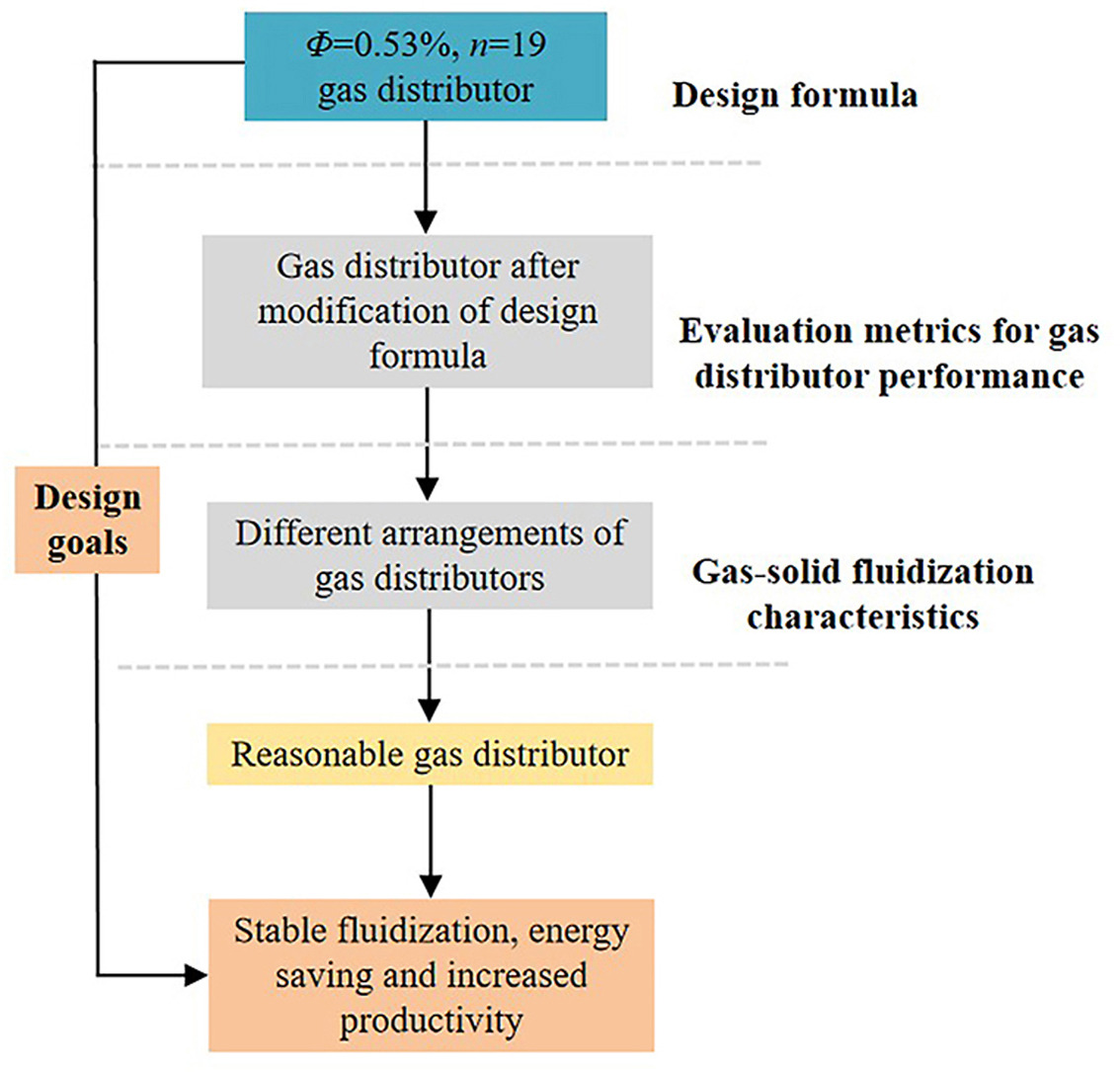

• Design formula for optimizing gas distributor.

• Indicators for evaluating the performance of gas distributors.

• Satisfactory performance improvement of the gas distributor after optimization.

• Study the influence of the arrangement of vent holes on gas-solid flow.

The structure of the gas distributor is closely related to the production efficiency of organosilicon monomers. To improve the production efficiency of organosilicon monomers, this study uses Eulerian-Eulerian two fluid model and proposes a design formula for the gas distributor to optimize the gas distributor. It is proposed that the pressure drop of the gas distributor, the velocity nonuniformity coefficient, the relative standard deviation of the solid holdup, and the solid particle dispersion coefficient are used to evaluate the performance of the gas distributor. The results show that the performance of the gas distributor is significantly improved when the opening ratio Φ = 0.53% is optimized to Φ = 0.18%, in which the relative standard deviation of the solid holdup is reduced by 22%, and the solid particle dispersion coefficient is reduced by 40%. On this basis, this article studies the influence of different arrangements of vent holes on gas-solid fluidization characteristics. The results show that the circular arrangement of vent holes is helpful to the mixing of gas and solid.