- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

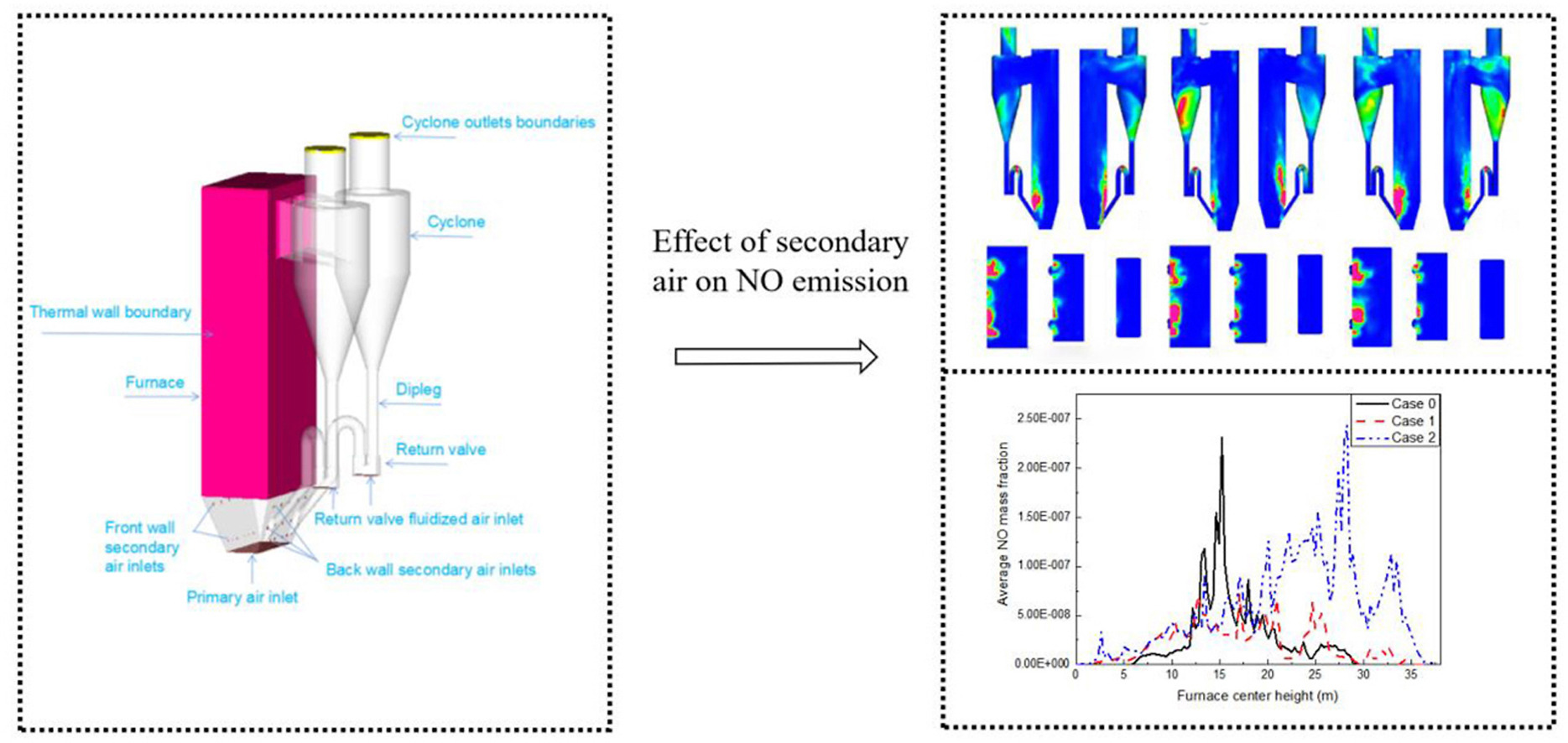

• Field experiment were restored by Computational Particle Fluid Dynamics numerical simulation.

• The combustion and NOx formation in the furnace under the operating conditions were analyzed.

• The effect of the secondary air ratio on combustion and NOx generation were predicted.

• Combined use of air classification and central air distribution can improve combustion stability and inhibit NO generation.

The 440 t/h circulating fluidized bed boiler was numerically simulated by the Computational Particle Fluid Dynamics (CPFD) method. The combustion characteristics of circulating fluidized bed boiler and the effect of secondary air on NO emission were investigated. The full-scale three-dimensional model of a 440 t/h circulating fluidized bed boiler was established. The rationality of the grid was validated by the experimental data of material layer resistance. The accuracy of the simulation was validated by measuring the temperature of each measuring point in the dense phase area. The combustion conditions in the furnace under different setting modes were simulated. The effects of secondary air rates on NO formation in fluidized bed were predicted. The results show that when the secondary air rate increases to 27%, the proper secondary air rate has a positive effect on the inhibition of NO generation, and the proper strengthening of the central air supply will improve the permeability of the secondary air and make the combustion more uniform and stable. When the secondary air rate increases to 33%, excessive improvement of air classification and central air distribution will affect the stability of circulating fluidized bed operation. Therefore, air classification and strengthening of central air supply can be used together to inhibit the generation of NO.