- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

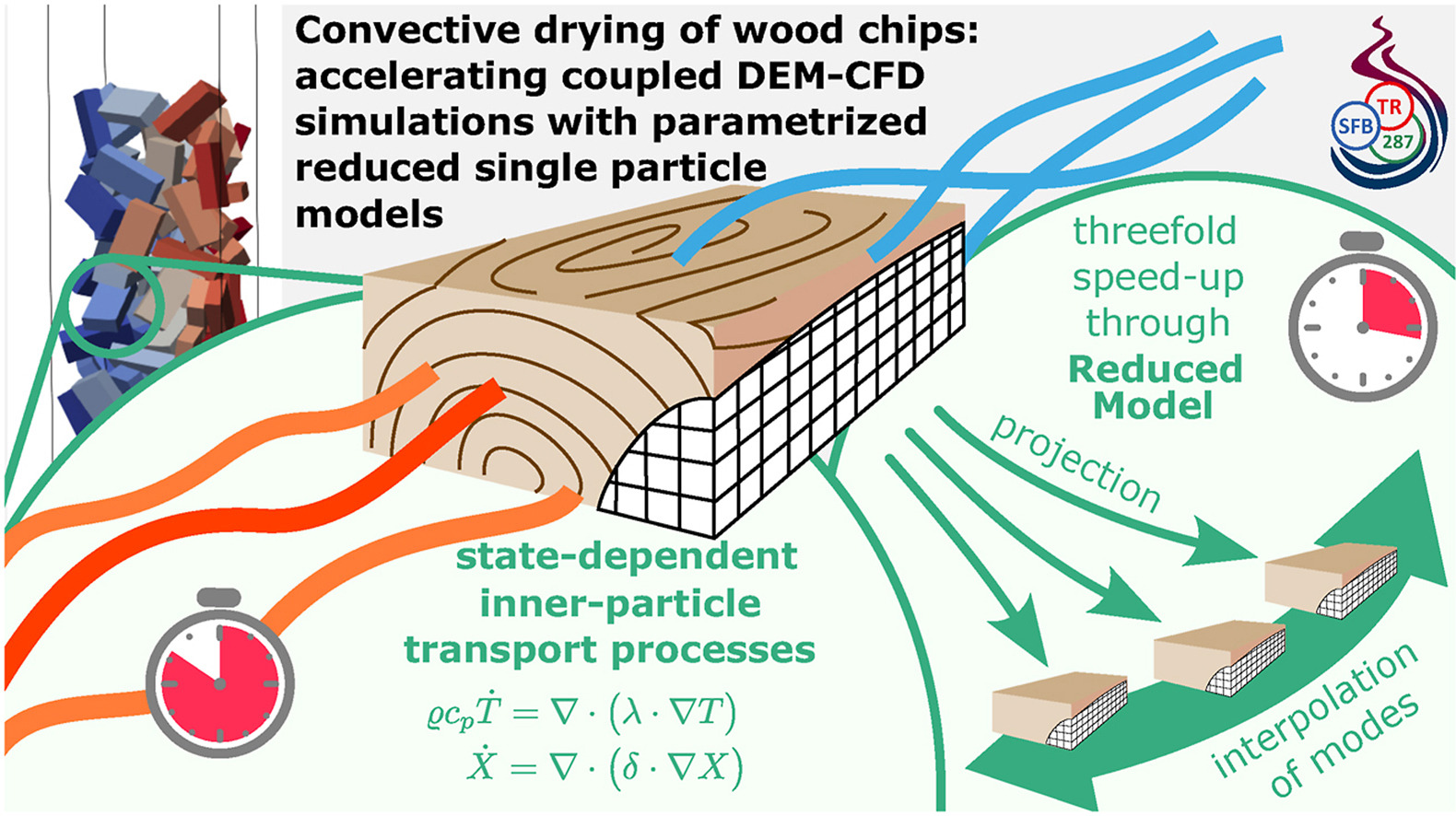

• Industry-scale reactive bulks can be simulated with DEM-CFD to very high precision.

• Resolving inner-particle processes for many single particles can be prohibitively expensive.

• Reduced models for single particles accelerate bulk simulations by a factor of three.

• The required precision of the reduced particle models can be achieved with nonlinear interpolation.

The simulation of industry-scale reactive bulks is challenging due to the complex interaction between fluid and particles. The particles in the bulk and their interaction with the fluid flow can be described by combined Discrete Element Method - Computational Fluid Dynamics (DEM-CFD) models. However, the computational cost of the Finite Volume (FV) methods deployed in these models can become prohibitively expensive, especially for high inner-particle resolution. Single particle Reduced Models (RMs) can be used to achieve both fast and accurate descriptions of the processes in each particle. As an example of bulk systems comprising heat and mass transfer, we compared FV and RM simulations for the drying of wood chips in a bulk reactor. A manifold-based nonlinear interpolation was applied to resolve changing boundary conditions for the RM. Our simulations showed that RMs provide accurate values for the thermodynamic state variables of the particles. Furthermore, the time required for the bulk simulation was reduced by 67% with the RMs. It is evident that simulations with high inner-particle resolution can be accelerated by RMs if manifold-based nonlinear interpolation is used to address changing boundary conditions.