- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Euler/Lagrange modelling of confined gas-particle flows with wall- and inter-particle collisions.

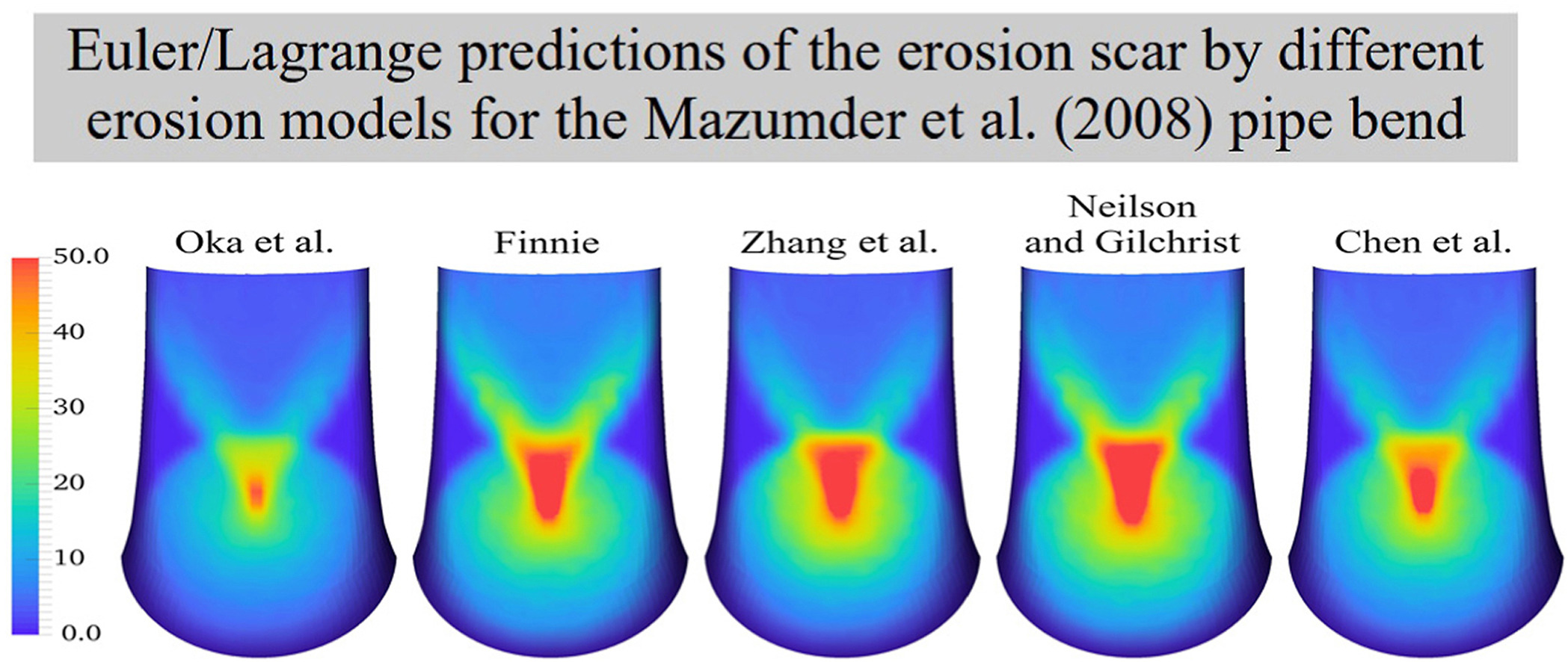

• Quantification of the performance of 5 erosion models in two different pipe bend erosion test cases.

• Wall roughness has a strong effect on erosion due to the modification of wall collision frequency.

• Modelling locally the roughness increase due to temporal erosion reduces erosion rate.

• A particle size distribution may slightly reduce erosion depending on the shape of the distribution.

The present research aims to assess the capability of a comprehensive Euler/Lagrange approach for predicting gas-solid flows and the associated solid particle erosion. The open-source code OpenFOAM® 4.1 was used to carry out the numerical simulations, where the standard Lagrangian libraries were substantially extended to account for all necessary models. Particles are tracked considering both translational and rotational motion as well as all relevant forces, such as gravity/buoyancy, drag and transverse lift due to shear and particle rotation. The tracking time step was dynamically adapted according to the locally relevant time scales, which drastically reduces computational times. Stochastic approaches are adopted to model particle turbulent dispersion, particle collisions with rough walls and particle-particle interactions. Five solid particle erosion models, available in the literature, were considered to estimate pipe bend erosion. Three study cases are provided to validate the adopted numerical approach and erosion models extensively. The first case intends to evaluate the ability of the extended CFD code to predict the behaviour of gas-solid flows in pneumatic conveying systems. This goal is achieved by comparing the numerical results with the experimental data obtained by Huber (1997) and Huber and Sommerfeld (1994, 1998) in a pneumatic conveying system. Here, the importance of considering inter-particle collisions and surface roughness for predicting particle velocity, mass flux and mean diameter distributions in gas-solid flows is highlighted. The second and third case intend to evaluate the ability of the erosion models in estimating bend erosion in diluted gas-solid flows. The erosion data obtained experimentally by Mazumder et al. (2008) and Solnordal et al. (2015) in very dilut pneumatic conveying systems is used for validating the numerical results, neglecting now inter-particle collisions and two-way coupling. Besides a comprehensive analysis of the different influential properties on erosion, the innovation of the present study is as follows. For the first time also a temporal modification of the surface roughness due to the erosion was considered in the simulations obtained from previous measurements (Novelletto Ricardo & Sommerfeld, 2020). As the surface roughness is increased due to erosion, eventually erosion rate becomes lower. This is the result of diminishing wall collision frequency. Simulations for several degrees of surface roughness showed that larger roughness is coupled with a drastic reduction of erosion. Hence, numerical simulations neglecting wall surface roughness are not realistic. The consideration of a particle size distribution instead of mono-sized computations showed a possible reduction of erosion rate. The detailed analysis of the different single-particle erosion models revealed that the model proposed by Oka et al. (2005) and Oka and Yoshida (2005) yields the best agreement with the measurements, however particle and wall properties are needed.