- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

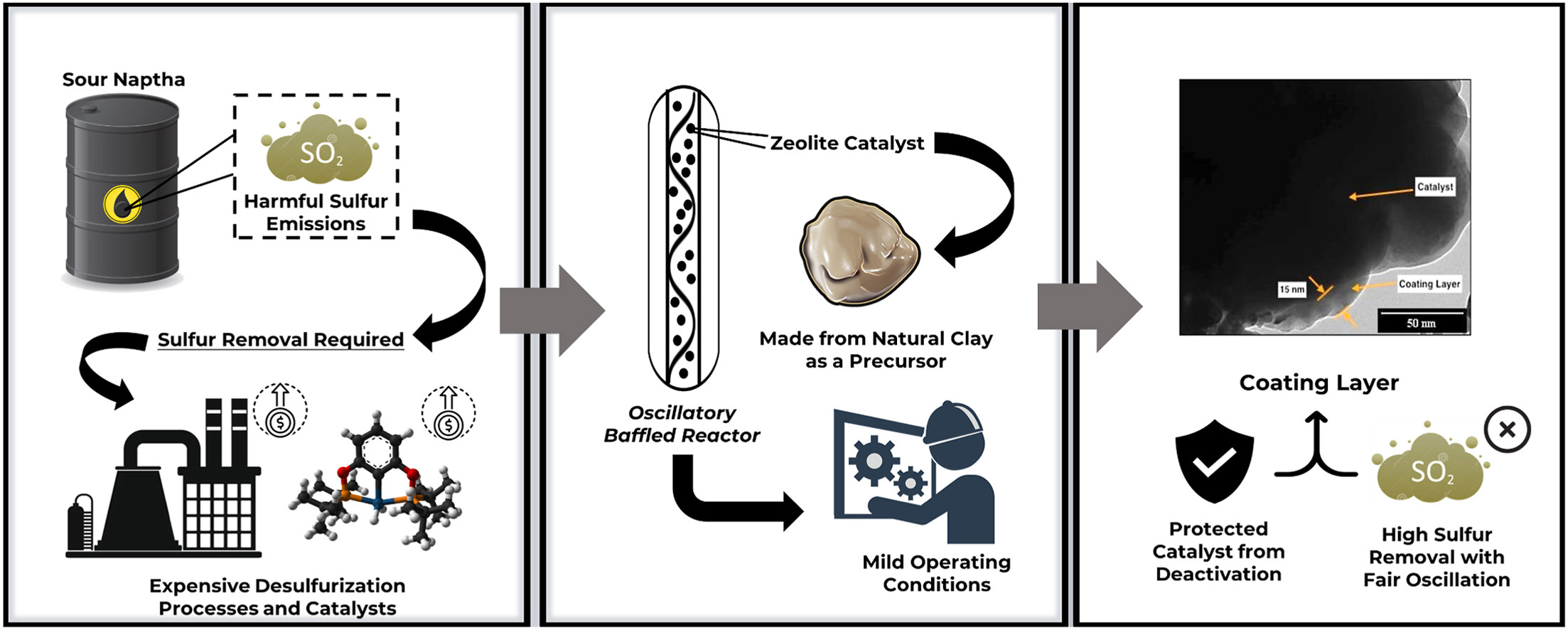

• High-stability oxidation catalysts from natural kaolin by sol-gel coating.

• Three-phase oscillatory baffled reactor utilized molecular oxygen for desulfurization.

• Mild kaoline-based oxidation process by oscillatory flow conditions.

• Non-extractive and continuous oxidation of sour heavy naphtha.

To meet the rapidly increasing demand for energy and the dramatic depletion of conventional crude oil, it is imperative to utilize sour naphtha. With no coke being produced, oxidative desulfurization (ODS) of naphtha lowers its sulfur content and average molecular weight. In this article, we outline a method for heavy naphtha non-extractive ODS using a very stable catalyst. The technique involves the use of a solid catalyst with oxygen gas as the oxidant. This necessitated relatively high mixing intensities; hence a three-phase Oscillatory Baffled Reactor (OBR) was used. The catalyst was based on the zeolite ZSM-5, prepared from natural kaolin by a series of delamination and activation steps and impregnated with Fe. A TiO2 nanolayer was applied, using the sol-gel method, to prevent rapid deactivation. The reactor performance was evaluated to minimize the sulfur content in the naphtha fuel. Due to the protective coating, the sulfur conversion stabilized at 90%. The results of this work establish the use of natural clay-based catalysts in a continuous, three-phase ODS, particularly with regard to proving long-term stability. It also showed that modest ODS can be achieved using an environmentally friendly oxidant, at mild operating conditions, whilst maintaining stability.