- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

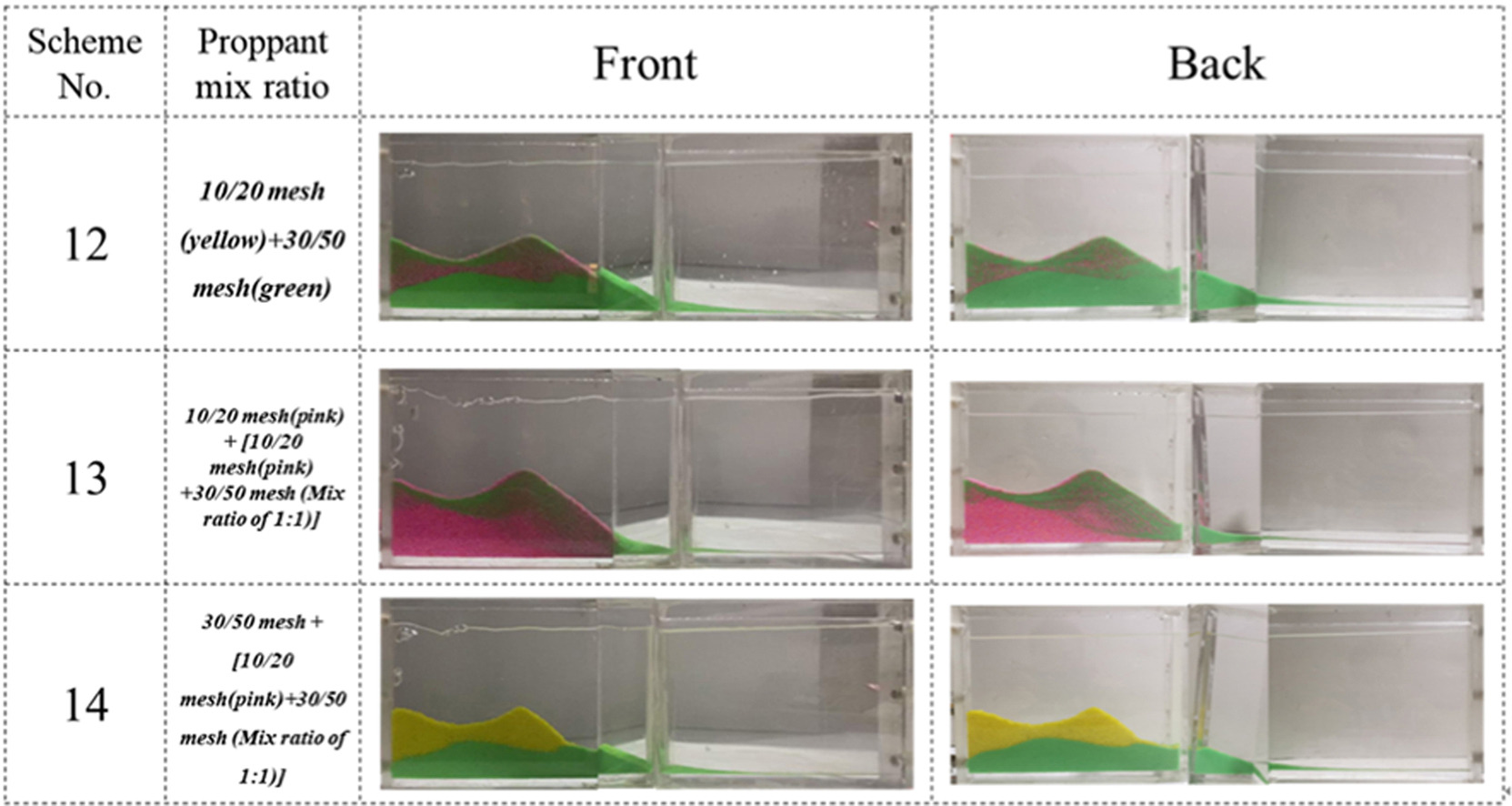

• Proppant transport is studied in tortuous fractures with different proppant size combinations.

• Small-sized mono-proppant has the highest transport efficiency in tortuous fracture.

• Proppant packing structure is different with the different proppant size combinations.

• An optimized alternating injection mode is recommended in this study.

• Proppant injection sequence of different size combinations significantly affects the proppant packing pattern.

Particle-fluid transport and placement mechanism in tortuous fracture played a crucial role in unconventional reservoirs. Currently, most studies focused on mono-size proppant with fluid transport processes in tortuous fractures. However, the mixture-size proppant with fluid movement mechanism in tortuous fracture was still uncommon. Therefore, this study designed and applied a series of experiments with a physical analog model of a tortuous fracture with 120° and 90°-angled bends and combined high-speed camera-based equipment. This experimental system was used to track different-mixture-sized proppant particle motion trajectories for a series of proppant injection schemes; The following conclusions were drawn from this study:1. The pile-up processes mechanism in all investigated schemes were similar and could be reduced to four main stages. 2. The packing structure at both sides of the fracture wall had different variation rates, which were controlled by the mix ratio (change from 1:1–1:5) of proppant size. 3. Some new packing patterns, such as Zebra Stripe, had occurred, controlled by the different proppant injection sequences. 4. Small-sized mono-proppant (30/50 mesh) had the highest transport efficiency in the tortuous fracture, followed by the mixed-sized multi-proppant (10/20 mesh:30/50 mesh), large-sized proppant (10/20 mesh) was the worst. 5. An optimized alternating injection mode was recommended as injecting small-sized proppant first (30/50 mesh) and followed by mixed-sized multi-proppant (10/20 mesh:30/50 mesh), which could contribute to obtaining the optimal both proppant packing height and travel distance in tortuous fracture.6. Two correlations were developed for predicting the proppant packing height and transportation distance.