- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

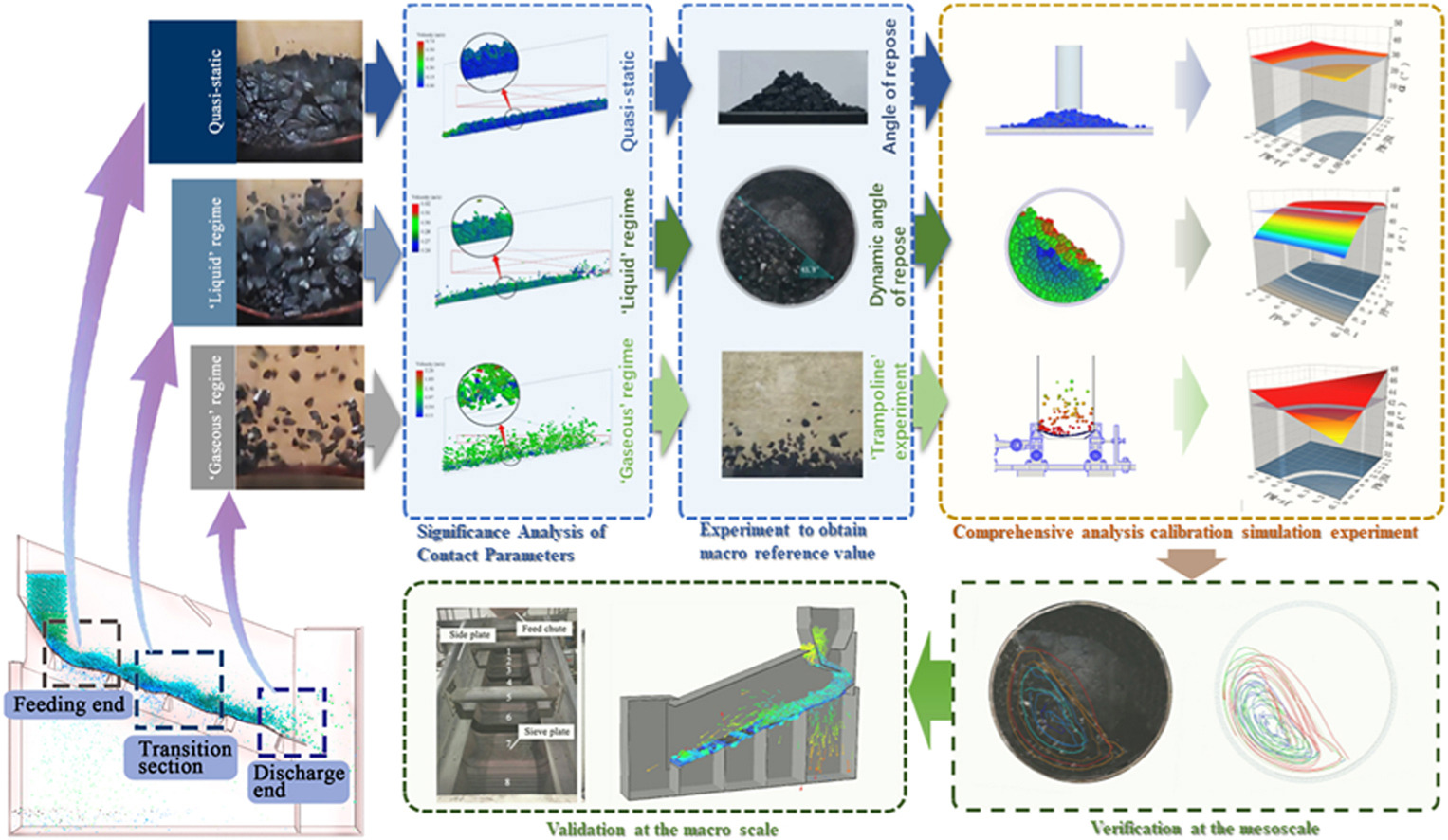

• A multi-regime combination calibration method based on particle flow regime characteristics was proposed.

• Dominant contact parameters for different flow regimes on a vibrating bed were studied.

• Calibration process was validated on both macroscale and mesoscale.

• A trampoline test was designed to calibrate the contact parameters in “gaseous” regime flow.

Discrete element method (DEM) is an effective approach for studying the screening process of flip-flow screens. However, there have been few studies focusing on the thick layer of sticky-wet particles on flip-flow screens. To achieve accurate simulations of the thick layer of sticky-wet particles on a flip-flow screen, firstly, the movement law of particle flow was studied, and a multi-regime combination calibration method based on characteristics of particle flow regimes was proposed. Based on the Plackett-Burman experiment, the curse of dimensionality caused by multi-state and multi-contact parameters was overcome. Subsequently, the lifting cylinder, rotating drum, and trampoline tests were carried out to obtain macroscopic reference values under various granular flow regimes. The calibration results were then determined using the response surface method and climbing algorithm. Finally, the calibration results were tested at both macroscopic and mesoscopic scales and compared with a commonly used calibration method. The results demonstrate that the calibration method, which considers the multi-state characteristics, improves simulation accuracy by 2%–10% and reduces the simulation error to less than 10%, thus meeting the requirements for engineering optimization of flip-flow screens.