- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

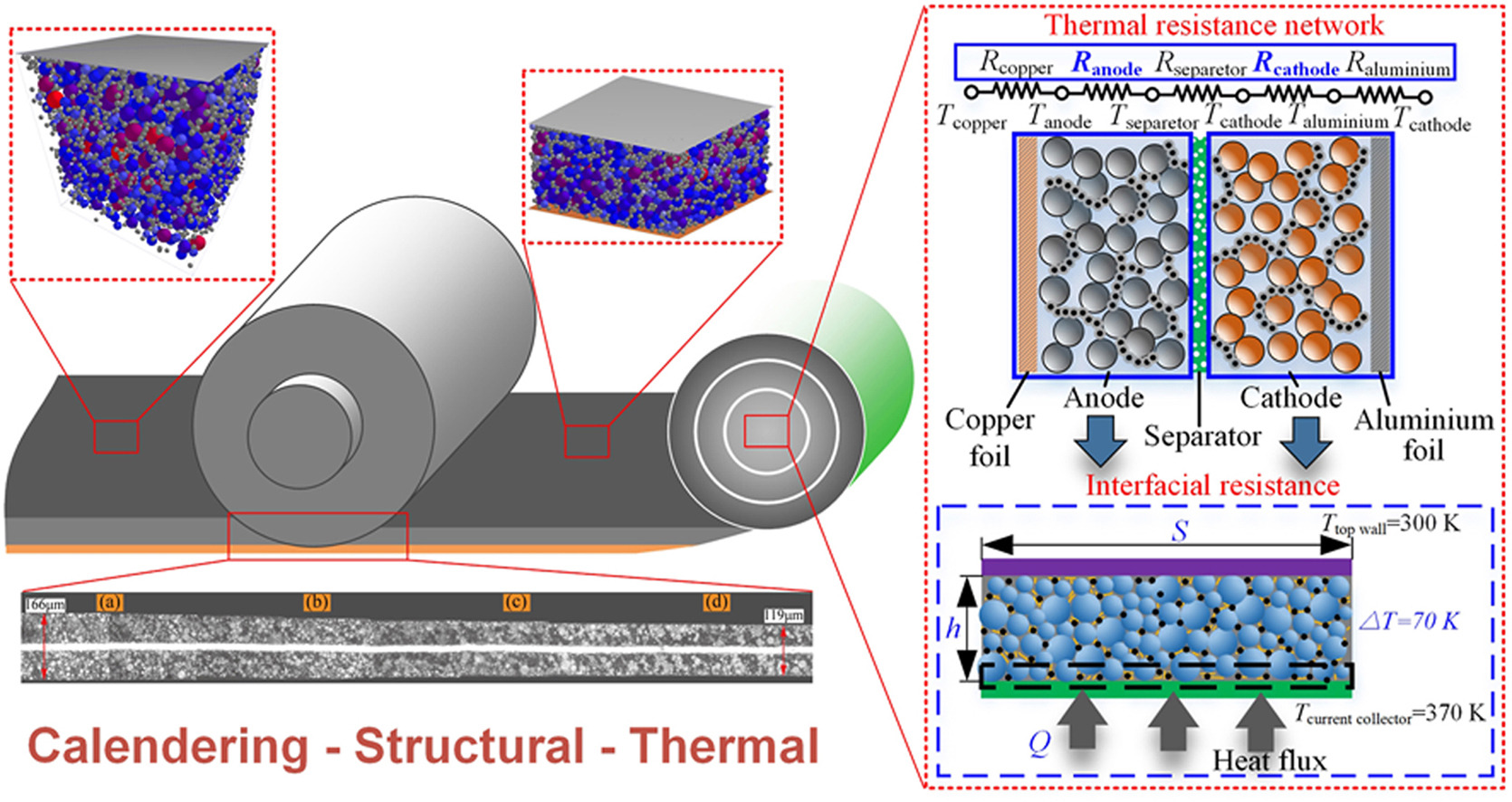

• Utilizing a DEM simulation to investigate correlation between calendering, structure, and heat transfer of NMC cathode.

• Uncovering the mechanism of the influence of structural anisotropy on heat transfer anisotropy of the electrode.

• Establishing calculation methods for the thermal conductivity of the electrode and the interfacial thermal resistance.

Elucidating the intricate correlation between calendering, structure, and performance is crucial to comprehending the relationship between performance parameters and process steps of lithium-ion batteries (LIBs). Discrete element method (DEM) simulations were adopted in this work to calculate the interparticle force and stress tensor under incremental calendering process conditions, which revealed the effect of the anisotropy of complex contact force network on the anisotropy of heat transfer within porous electrode. The thermal conductivity of electrode was predicted using porosity to characterize the process–structure–performance correlation. The comprehensive influence of contact number and contact area between particles and current collector determines the magnitude of interfacial thermal resistance and interfacial heat transfer coefficient. For the first time, this work quantitatively analyzed the structural mechanics and heat transfer mechanism during calendering process of porous electrodes, and the results indicate a promising way to optimize and design battery electrode structures.