- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

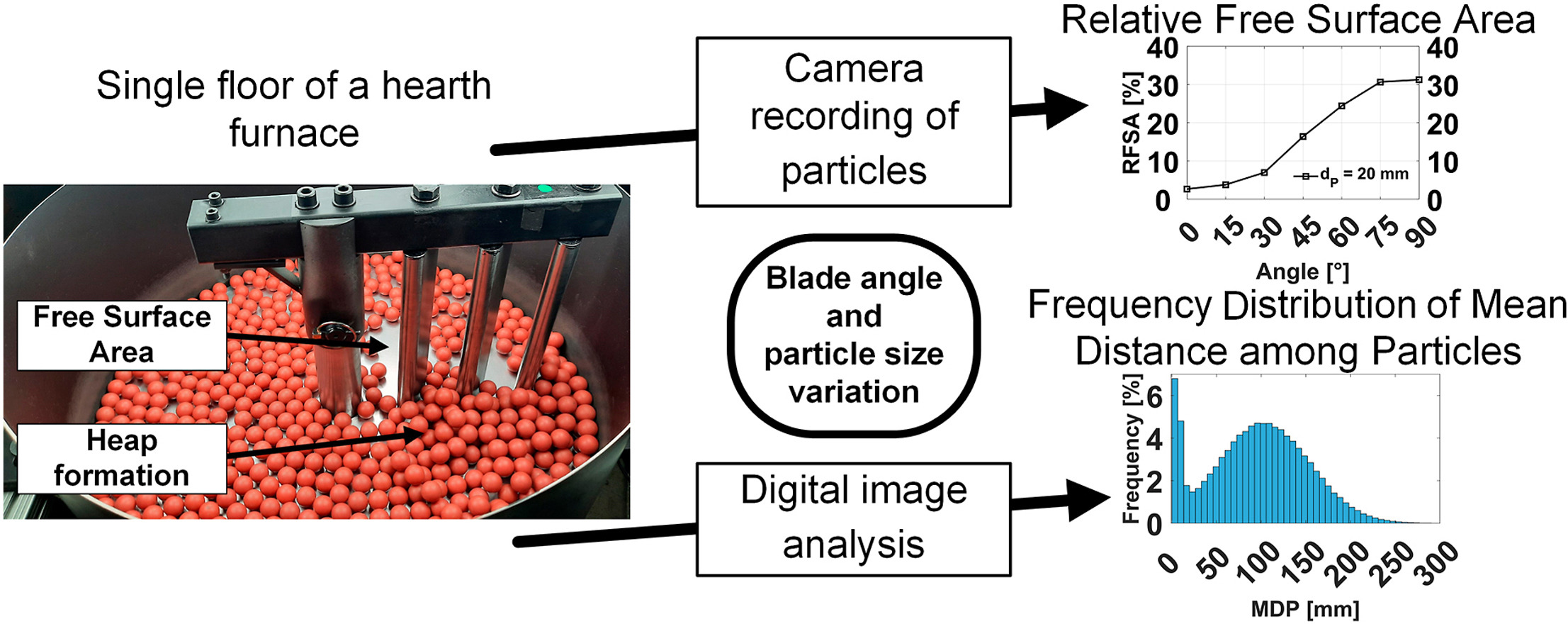

• An increase of particle free surface area indicates enhanced heap formation.

• Frequency distribution of distance among particles is a measure for spatial arrangement of particles.

• Blade inclination increases particle free surface area.

• Particle free surface area is a non-monotonous function of particle size.

• Frequency distribution of the distance among particles is typically bimodal.

In industry, multiple hearth furnaces are used for the thermal treatment of particulate material. The current contribution concentrates on the experimental analysis of particle mechanics for a batch-operated single floor of a multiple hearth furnace. The particles are agitated on the circular floor by a single, rotating rabble arm equipped with three flat rabble blades of 10 mm thickness. The blade angle, defined as the angle, which the blade is inclined against the tangential direction, is varied from 0° to 90°. A single layer of spherical polyoxymethylene (POM) particles with three different diameters (5, 10 and 20 mm) is placed on the floor. To analyze the results, two parameters have been extracted from image analysis when the bed of particles is agitated, first, the area not covered by particles and second, the frequency distribution of the mean distance among the particles. The particle free surface area increases with the inclination of the blades. The evolution of the particle free surface area differs for the different particle diameters. In general, the maximum particle free area for all blade angles is the largest for the 5 mm particles followed by the 20 mm particles. For the 10 mm particles, the particle free surface area starts for a blade angle of 0° at larger values than for the 20 mm particles but the values fall below the values for the 20 mm particles for larger blade angles. The reason for this behavior is discussed in detail. The mean distance among the particles is a parameter characterizing the length scales dominating the effects on the floor. The frequency distribution of the mean distance among particles provides information about the morphology of the particle bulk, for example, whether the free surface area is interspersed with particles.