- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

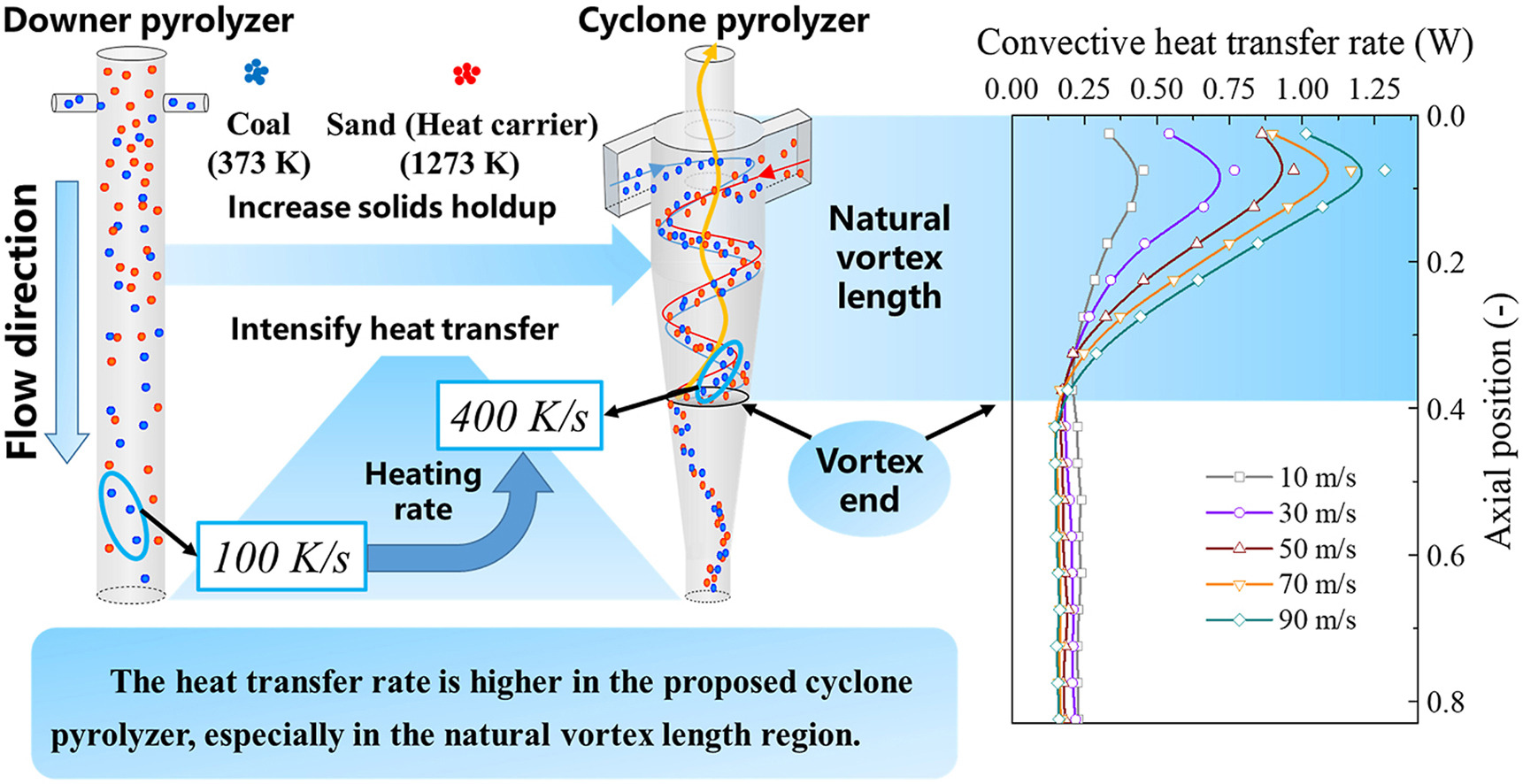

• Gas-solids heat transfer process of cyclone pyrolyzer is analyzed.

• Heating rate within the cyclone pyrolyzer is 4 times higher than that in downer.

• Higher heat transfer rate is shown in the natural vortex length region.

• A significant inlet gas velocity can yield a maximum temperature of coal particle.

Fast heat transfer in the pyrolyzer can increase the yield of pyrolysis gas and tar, and improve the quality of tar. Compared with the downer pyrolyzer, the cyclone pyrolyzer can simultaneously achieve high solids holdup and violent turbulence, and correspondingly faster heat transfer. In this work, the heat transfer behavior in the cyclone pyrolyzer is specifically studied using the computational fluid dynamics-discrete element method. The simulation results reveal that the gas-solids heat convection contributes mainly to the heat transfer process, and the heat radiation and conduction are relatively small and almost negligible, respectively. Compared with the downer pyrolyzer under the same operating conditions, the heating rate is significantly increased in the cyclone pyrolyzer. By analyzing the flow characteristics in the cyclone pyrolyzer, it is found that the region of high convective heat transfer rate coincides with that of natural cyclone length. Additionally, the final coal temperature increases with the increase of gas velocity and exists a maximum value. These results can offer some qualitative understanding of the heat transfer behavior in the cyclone pyrolyzer.