- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

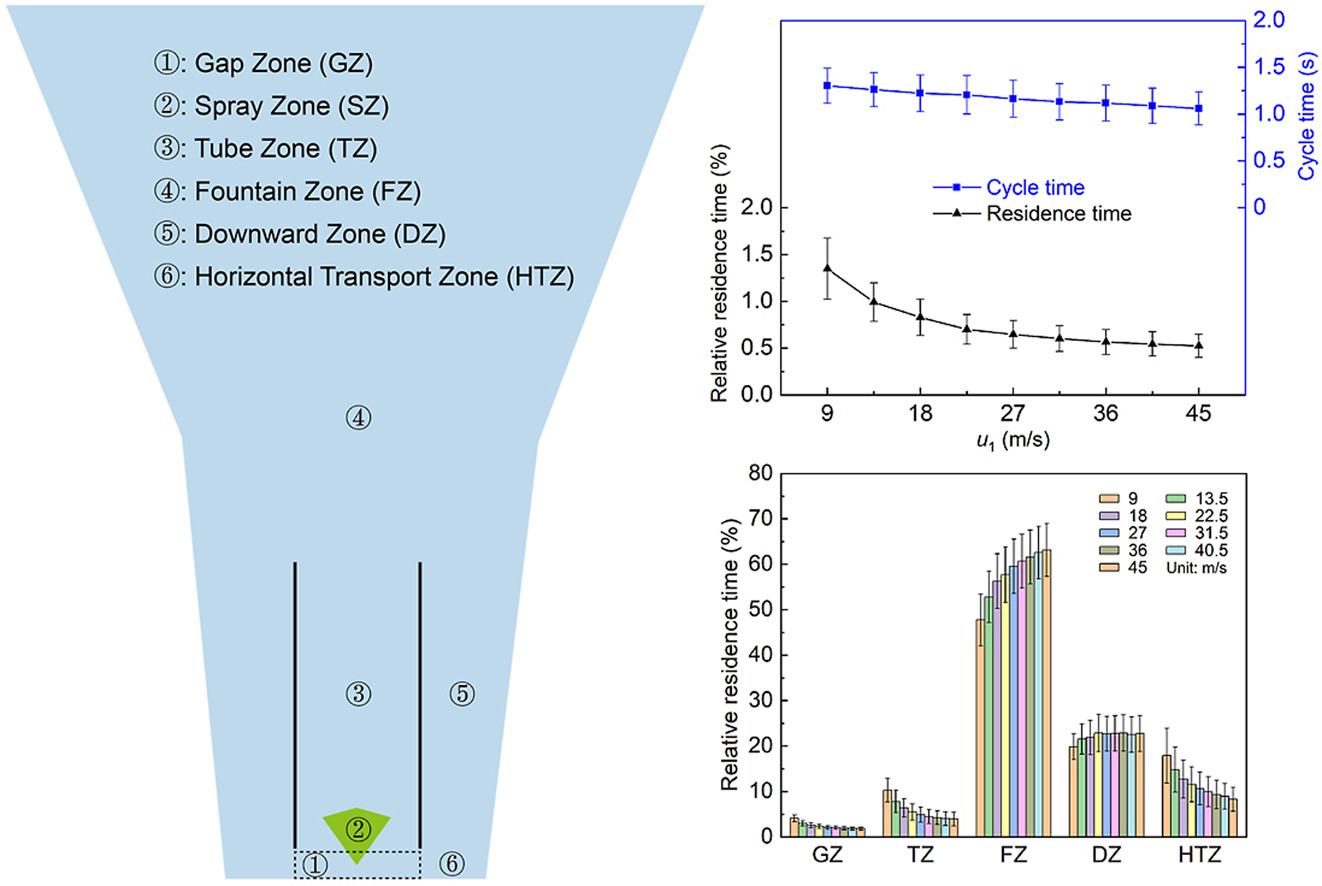

• A coupled CFD-DEM method was employed and the CFD part was validated.

• The effect of gas velocity, gap height, tube length and batch volume was studied.

• The de-fluidization problem was identified and the solutions were provided.

• The shielding effect of coarse particles to fine particles was analyzed.

A coupled CFD-DEM method was used to study the hydrodynamics of a Wurster coater. Firstly, the CFD part of the model was validated by the accurate prediction of the pressure drops over a pseudo-2D fluidized bed under various gas velocities. The effect of gas velocity, gap height, tube length and batch volume of the particles on the cycle time and the residence time of the particles was thoroughly investigated. The central jet gas velocity u1 was found to speed up the particle cycle but undermine the coating efficiency. The gas velocity at the horizontal transport zone u2 was able to promote the horizontal transport of the particles but should not be too high, otherwise, it would obstruct the normal falling back of the particles in the downward zone. Big gap heights would decrease the coating efficiency but tube length had little impact on that. The increment of batch volume would commonly abase the cycle time and the working efficiency under a given u1. The de-fluidization problem arose when the batch volume increased to 550 mL. However, this problem could be swept out by the optimization of u1 and u2. In a mixture of different sizes, the coarse particles enjoyed higher coating efficiency and could travel closer to the nozzles. This may shield the fine particles from getting enough coating liquids, and thus coarse particles and fine particles were not recommended to get coated in the same batch.