- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

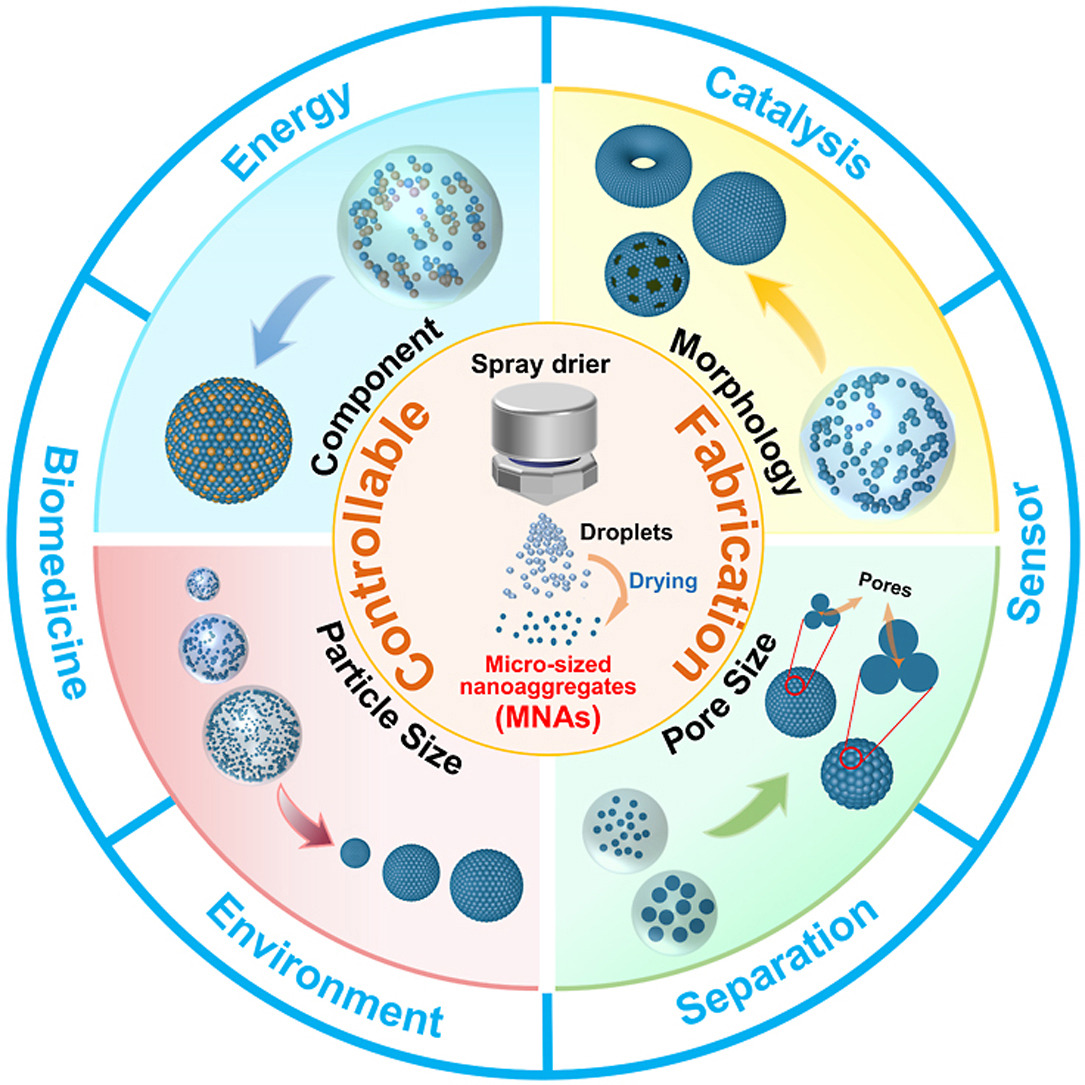

• Micro-sized nanoaggregates (MNAs) are highly desirable due to their advantages.

• Spray-drying technology is a versatile tool in construction of MNAs.

• Size, morphology and structure of MNAs are controllable in spray drying.

• Spray-dried MNAs are used in a wide range of applications.

The applications of nanoparticles suffer from their extremely small size and intrinsic trend of agglomeration. Rearranging nanoparticles to form micro-sized nanoaggregates (MNAs) with increased size, ordered structure, as well as controllable size, shape, and morphology is a crucial step in various fields of science and technology to maintain the unique characteristics of nanoparticles while obtaining greatly enhanced or new performance at the microscale. The structure of MNAs prominently affects their functionality, which is determined by the arrangement of nanoparticles and the interaction between primary particles. Several methods have been proposed to prepare the MNAs, in which spray-drying technology stands out considering the feasibility, scalability for industry, cost, and efficiency. Forced assembly of nanoparticles through spray-drying under tunable process parameters yields diverse physical properties and structural arrangements of nanoparticles of the MNAs, they therefore exhibit enormous potential in a wide range of application fields. This review presents the construction and applications of spray-dried MNAs. The factors that influence the size, morphology, and structure of the MNAs are discussed in detail. In addition, the outstanding application performance resulting from the tightly packed nanoparticles in regular-shaped MNAs obtained by the spray-drying process is illustrated.