- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

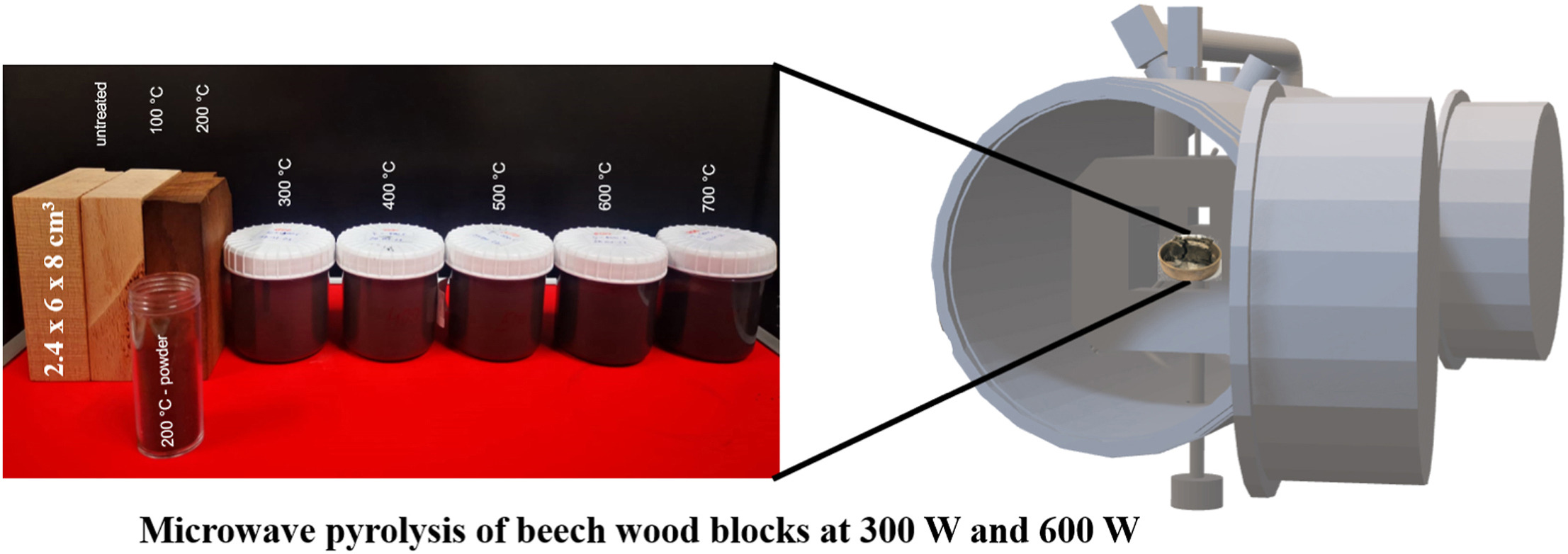

• Microwave assisted pyrolysis of thermally thick beech wood blocks in a lab-scale reactor operated at 2.45 GHz.

• Process conditions monitored based on sample weight, temperature and reflected power.

• Power-level dependent mass conversion and formation of hot spots observed.

• Similar product properties as with conventional pyrolysis at 700 °C obtained at 600 W.

• Dielectric and physico-chemical properties affected by the process conditions.

Pyrolysis of thermally thick beech wood blocks with a size of around 2.5 × 8 × 6 cm3 (width × length × height) was carried out in a lab scale microwave reactor with a frequency of 2.45 GHz, operated, both, at 300 W and 600 W under inert conditions, using N2 at around 400 mbar absolute pressure. The microwave cavity had a size of 20 × 20 × 20 cm3. The specific energy supply referred to the untreated wood block was 4–8 W/g, with slight variations depending on the initial water content. The mass loss and the reflected microwave power were in-situ monitored during the experiments. The sample surface and chamber temperatures were measured with a pyrometer and a thermocouple, respectively. Physico-chemical and dielectric properties of the produced solids were investigated and compared to those of chars produced under conventional pyrolysis using the same raw materials. It is shown that the complex dielectric permittivity of the solid products changed drastically during the pyrolysis process, with increasing heating properties as the conversion process evolved. This was easily achieved using 600 W without susceptors. However, 300 W was not enough to achieve a high conversion degree, independently of the irradiation time. This, together with the physico-chemical analyses of the solids, hinted to the importance of the transport kinetics in thermally thick materials, although further investigation is still required.