- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

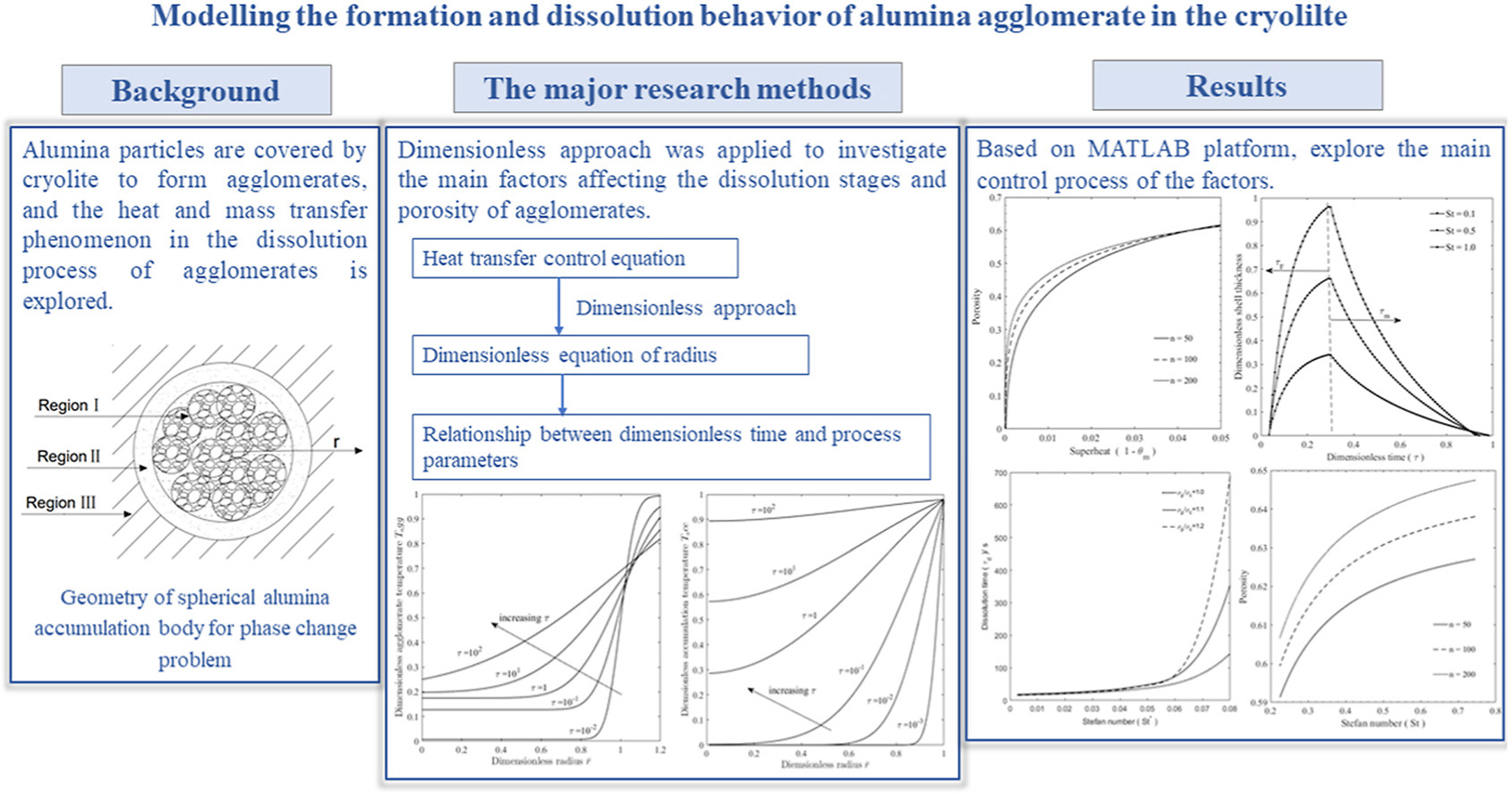

• A semi-analytical mathematical model was established coupling heat and mass transfer.

• Formation, melting and dissolution process of alumina agglomerates were formulated.

• Penetration and solidification of cryolite were considered based on packing theory.

• Time duration for each stage and the maximum diameter of agglomerates were derived.

• Dimensionless method was employed to analyze the influence factors on dissolution.

The presence of alumina agglomerates seriously affects the current efficiency of the aluminum electrolysis process. Clarify the dynamic dissolution process of agglomerates is essential to improve the current efficiency of aluminum electrolysis. A mathematical model is proposed to describe the different phenomena from the formation until complete dissolution of agglomerates. Considering permeation and solidification processes of cryolite, a semi-analytical mathematical model is developed to formulate the formation, melting and dissolution processes of agglomerates, and the time duration for each stage is deduced. Porosity and heat mass transfer of agglomerates are explored based on the packing theory and mechanism of heat mass transfer in wet porous media. Dimensionless approach is applied to investigate the main factors affecting the dissolution stages and porosity of agglomerates. The results show that the superheat has a great influence on the formation and melting stage, the diameter of agglomerates can reach 14.93 mm for 200 particles agglomerated. The density decreases with the increase of agglomerated particle number, which varies in the range of 2.27–2.28 g/cm3. The average dissolution rate of agglomerates is about 1.83*10-5 - 2.95*10-5 kg/s within the range of alumina concentration in this study.