- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

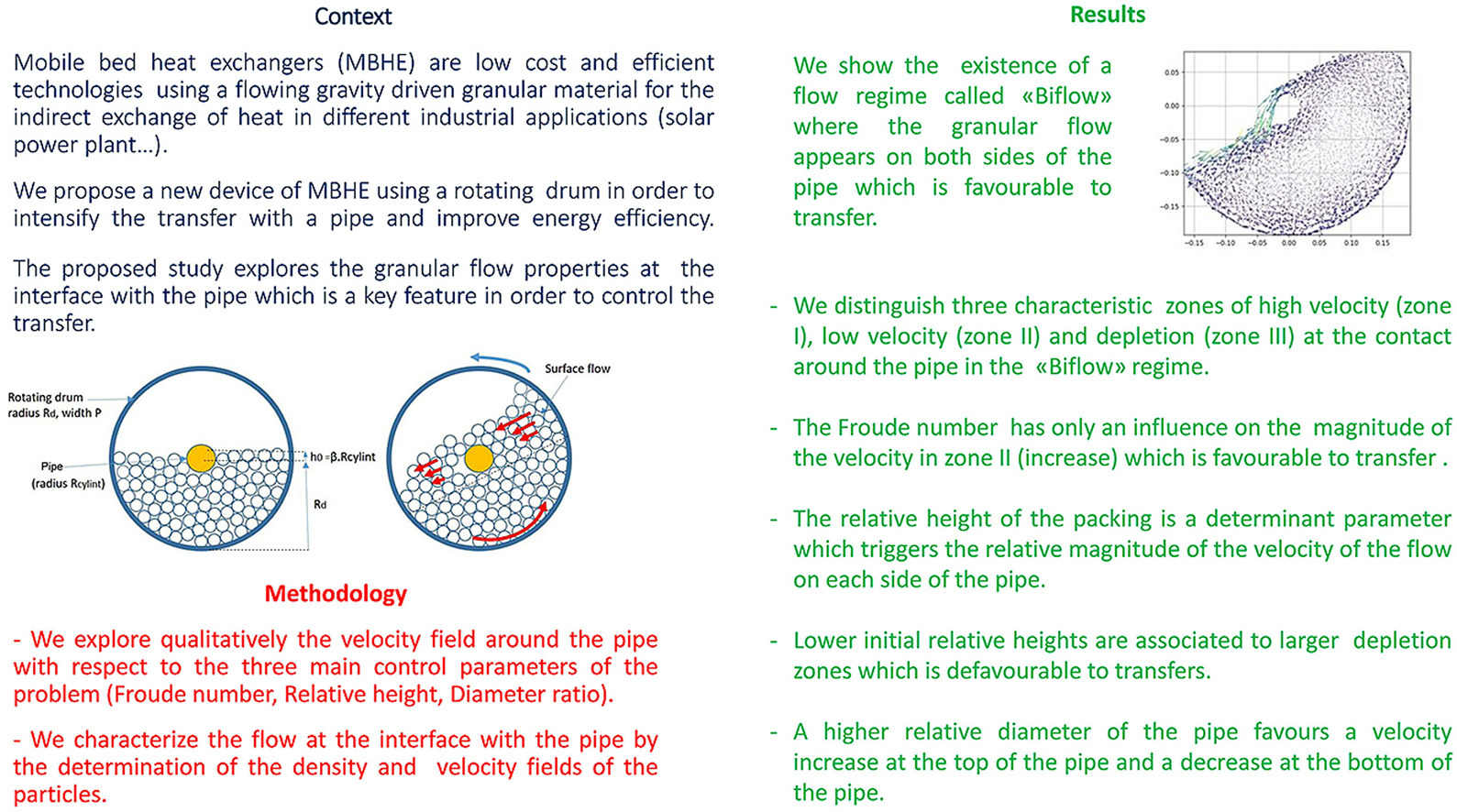

• A new mobile bed heat exchanger is proposed based on a granular flow in a rotating drum and a pipe along its central axis.

• A flow regime (Biflow) can occur on both sides of the pipe which maximizes convection and is thus favourable to transfers.

• The velocity at the bottom of the pipe (low velocity zone) increases with the Froude number which is favourable to transfer.

• The initial height of the packing triggers the relative magnitude of the flow on each side of the pipe in the Biflow regime.

• Lower initial heights are associated to larger depletion zones which is unfavourable to transfer.

A new mobile bed heat exchanger is presented in this work which is composed of a flowing granular material in a rotating drum and a cylindrical pipe with potential interest in different energy applications as cooling, heating or heat recovery processes. An optimal design of the device requires a characterisation of the phenomena involved at the interface between the granular flow and the pipe. The process is modelled by the discrete element method and a global classification of the flow patterns around the pipe is presented with respect to the three main control parameters of the problem: the Froude number, the diameter ratio and the relative filling height of the drum. The second part is devoted to the characterisation of the structure of the flow at the interface (velocity field, density field) in particular in a so-called Biflow regime where granular motion occurs above as well as below the pipe which is favourable to transfer by convection. A typical behavior at the interface with the pipe consists of a zone I with high velocities of particles at the top of the pipe, a second zone with quasistatic particles or low velocity particles at the front and at the bottom of the pipe and a last zone III of depletion of particles at the back of the pipe. The Froude number has a limited effect on the features of this structure on the first layer in the range of Froude numbers considered whereas the relative height is a more determinant parameter to control the relative magnitude of velocities in zone I and zone II as well as the extent of the depletion zone. This first hydrodynamical characterisation can shed light on the dynamical regimes with improved transfer between the particles and the pipe boundary.