- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

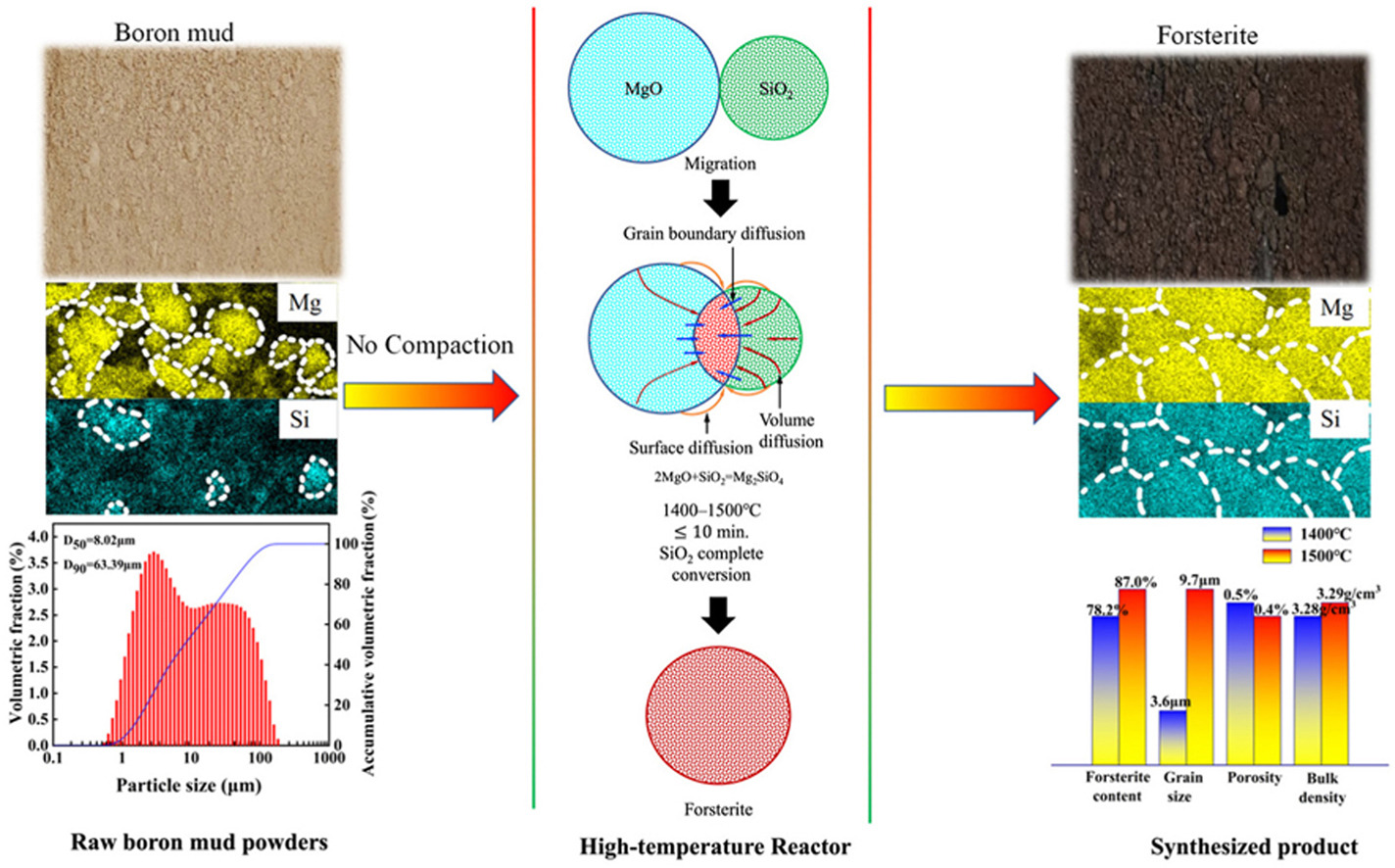

• Boron mud can be converted to forsterite-rich materials at 1300–1500 °C within minutes.

• Aggregated but non-briquette fine particles exhibit superior reaction performance.

• Over 90% of SiO2 in boron mud is converted to form forsterite after 10 min of reactions.

• Forsterite content is higher than 85% after 10 min of reactions at 1400–1500 °C.

• The synthesized powder materials are over 98% in terms of relative densification.

Forsterite is a highly demanded material in high-temperature industries due to its superior performance in elevated temperatures. This study proposes synthesizing high-quality forsterite via high-temperature thermochemical reactions using abundant boron mud waste. The new synthesis method capitalizes on the high reactivity of fine raw powder materials, enabling the reaction to reach completion at low temperatures rapidly. The chemical characteristics, microscopic morphology, and structure of synthesized samples are systematically studied using XRD and SEM. The results confirm that boron mud can be efficiently transformed into forsterite after 10 min of reactions at 1500 °C. The synthesized products attain over 98.7% densification and contain more than 85.0% forsterite with well-developed grains. The activation energy of forsterite grain growth in the 1100–1500 °C temperature range is 165.5 kJ/mol. This study provides a low-cost method for producing forsterite and an efficient and environmentally friendly solution for treating solid waste.