- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

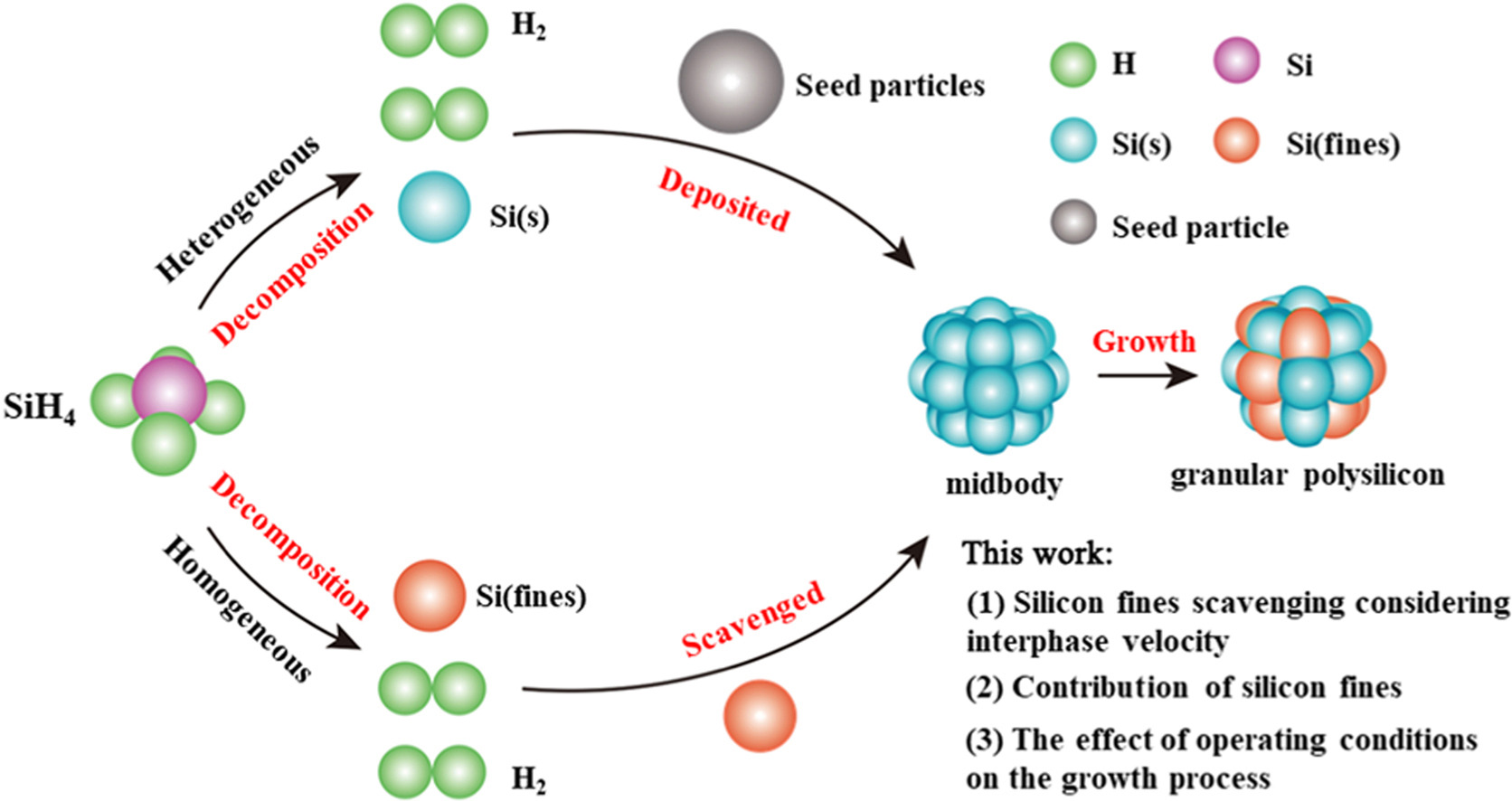

• Considering role of silicon fines scavenging based on phase velocity differences to study granular silicon growth processes.

• Heterogeneous deposition occurs in the bottom region.

• The dilute phase region is dominated by the silicon fines scavenging effect.

• Operating conditions affect the formation of silicon fines and growth rate.

• Exploring the selectivity of granular silicon growth.

Operating conditions strongly affect the yield and quality of polysilicon in a polysilicon fluidized bed. In this study, a new model of polysilicon fluidized bed was established using the Euler–Euler model coupled with population balance model (PBM), which was combined with fluid flow, heat, and mass transfer models, while considering the scavenging effect of silicon fines. The effects of different operating conditions on the deposition and formation rates of silicon fines were investigated. Results show that the model can correctly describe the particle growth process in the fluidized bed of polysilicon. The silicon fines and the interphase velocity difference show “N”- and “M”-shaped distributions along the axial direction, respectively. The particle temperature and concentration near the wall are higher than those in the central region. The decomposition of silane in the bottom region of the bed is dominated by heterogeneous deposition. The scavenging of silicon fines occurs in the dilute-phase region. The effects of operating conditions, i.e. inlet gas temperature, silane composition, and gas velocity, on the reactor performance were also explored comprehensively. Increasing the inlet gas composition and velocity enhances the formation rates of solid silicon and fines. Increasing the inlet gas temperature promotes the growth of solid silicon and inhibits the formation of silicon fines. High fluidization ratio, low inlet silane concentration, and high inlet gas temperature enhance the selectivity of silicon growth.