- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

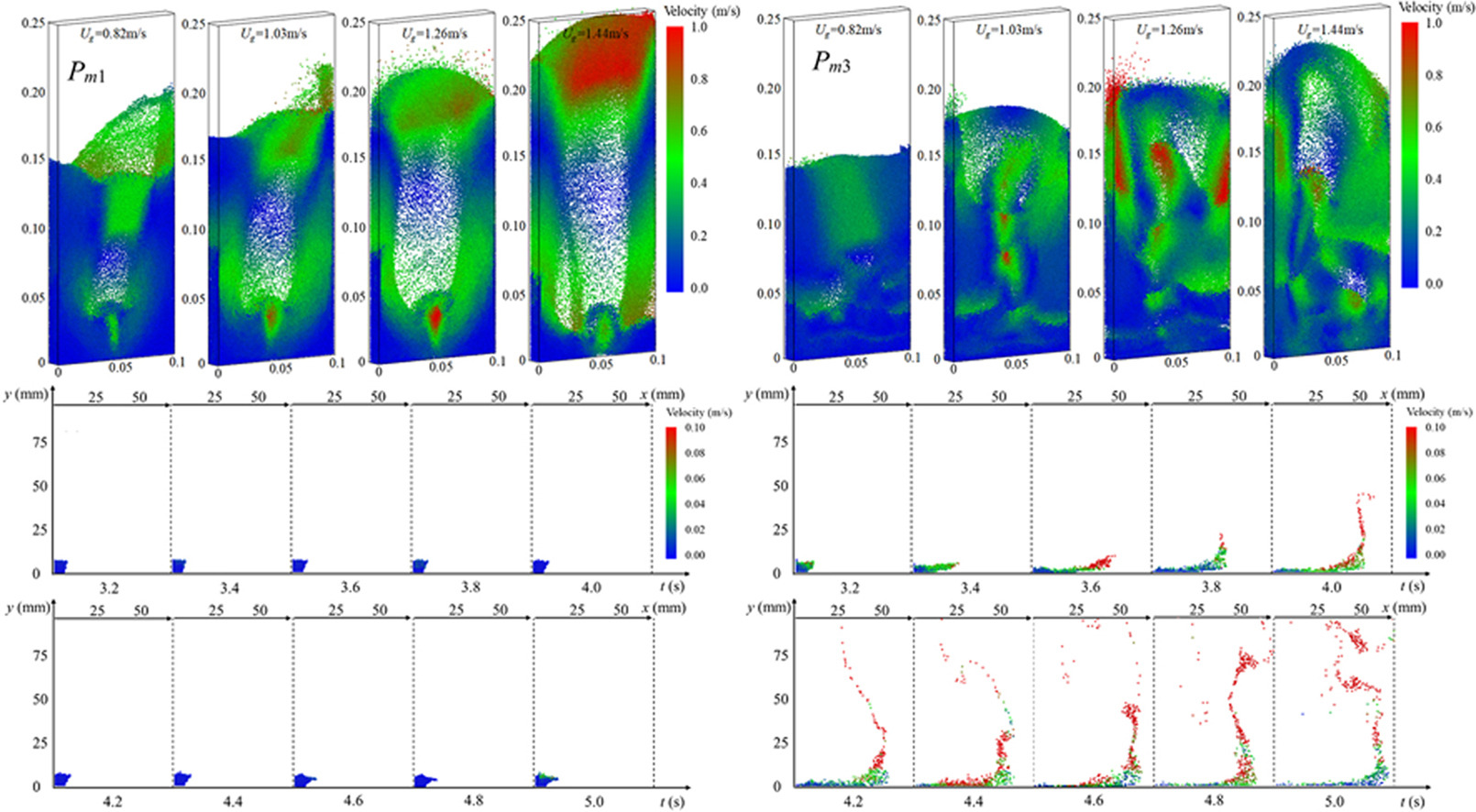

• CFD-DEM coupled with the porous medium model is proposed.

• The accuracy of the CFD-DEM coupled with the porous medium model is verified.

• The flow resistance of the porous medium affects the fluidization behavior.

• The mixing quality is significantly improved due to the high flow resistance.

• The particle trajectories of the dead zone are affected by the flow resistance.

Gas–solid bubbling fluidized beds are widely used in chemical, energy, construction, and other industrial fields due to their excellent fluidization performance. 2D-fluidized beds with planar rectangular columns of finite thickness are widely used in fluidized bed studies, and it is essential for understanding the hydrodynamics of gas-particle systems. Moreover, the distributor (porous medium) at the bottom of the bed has a crucial influence on the fluidization performance of the 2D-fluidized bed. In this work, the fluidization mechanism and gas–solid dynamic characteristics of the fluidized bed under three porous media are studied by CFD–DEM coupled with the porous medium model, and the accuracy of numerical simulation is verified by a high-speed photography experiment. Results show that with the increase in the flow resistance of the porous medium, the average and standard deviation of the bubble diameter decrease, and the time and position of particles in the dead zone to participate in the core–annular flow advance. At a low fluidization velocity, the dead zone in the bed can be considerably reduced by increasing the flow resistance.