- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

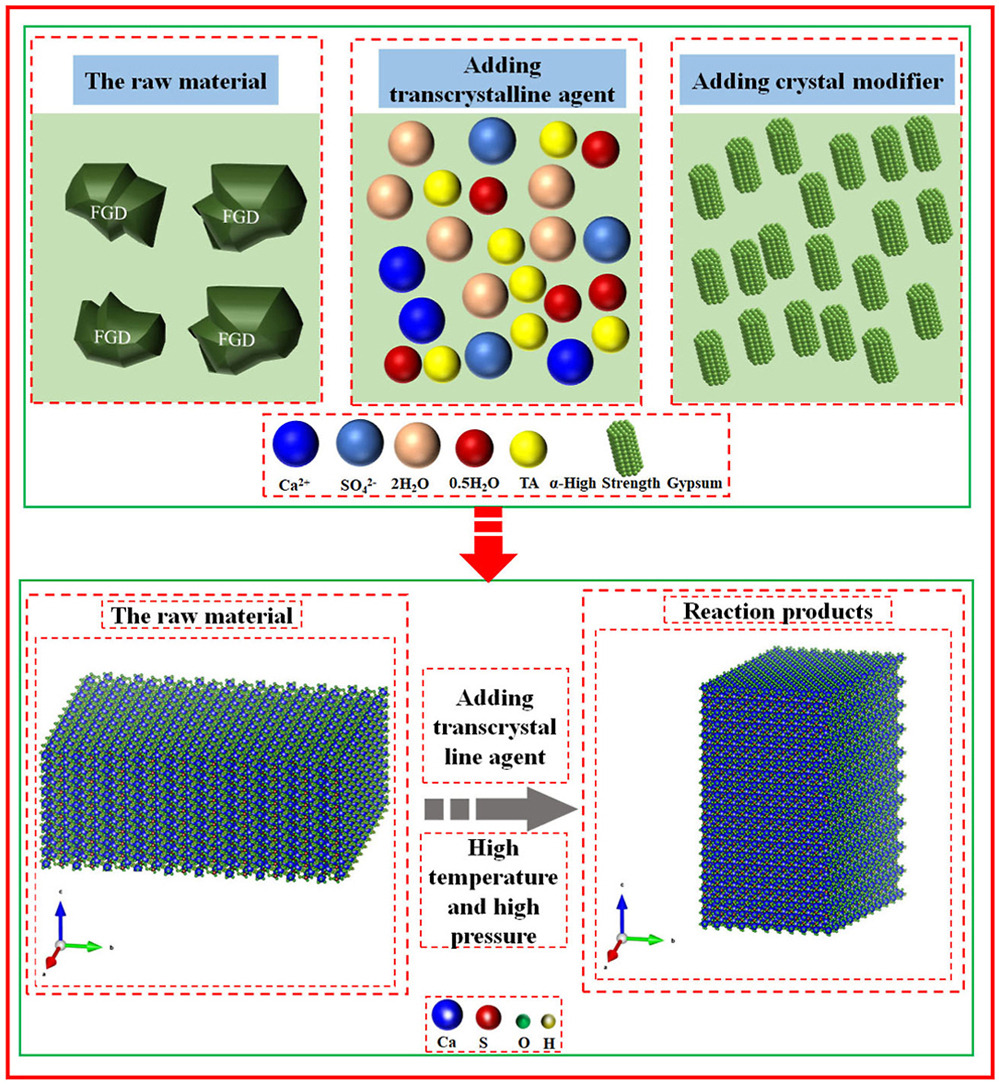

• Effect of a crystal-transforming agent on the performance and mechanism of FGD gypsum.

• Tiny, macro, and formation mechanisms of α-high-strength gypsum under action of a crystal modifier were explored.

• Better-prepared α-high-strength gypsum crystals are short columnar, with an aspect ratio in the range of 1–3.

This paper investigates the impact of flue gas desulfurization (FGD) gypsum's crystal modifier on the characteristics and microcosmic mechanism of α-high strength gypsum. The results demonstrate that all three crystal modifiers can convert FGD gypsum to α-high-strength gypsum. Citric acid (CA) has the most significant influence on α-high-strength gypsum, and the prepared α-high-strength gypsum is short columnar, with an aspect ratio in the range of 1–3, and has a faster setting time, a larger specific surface area, and a smaller standard consistency, higher compressive strength, greater surface hardness, and smaller crystal particle size. The initial setting time of the α-high-strength gypsum manufactured with CA crystal modifier was decreased by 36% compared to the blank sample, the final setting time was lowered by 37.5%, and the water consumption of the standard consistency was reduced by 8%. The maximum strength is 32 MPa after 2 h, the absolute dry compressive strength is up to 38 MPa, and the surface hardness is improved by 24.43%.