- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

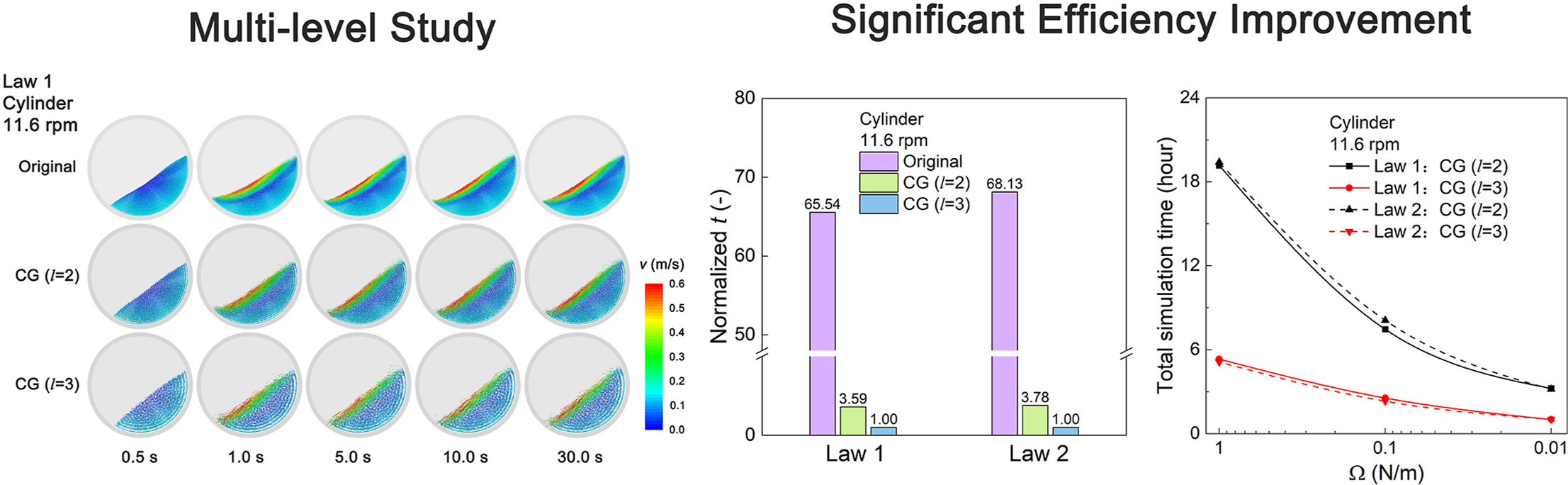

• A coarse-grained model is proposed for cylinder particle flow.

• Cylinder particle flow in a drum is predicted using original and coarse-grained models.

• adequacy of coarse-grained approach is evaluated using a multi-level methodology.

• Coarse-grained model accurately predicts the dynamic characteristics of cylinder particle flow.

• Coarse-grained model evidently improves simulation efficiency.

The coarse-grained discrete element method (DEM) is probably a feasible option for simulating an actual drum-type biomass boiler, which contains over 10 million cylinder particles. A multi-level study was conducted based on particle and coarse-grained level data to evaluate the adequacy of the coarse-grained approach in terms of geometrical characteristics, kinematic features, and dynamic properties. Two scaling laws for contact parameters were used and compared during the simulations. The results show that the coarse-grained approach can accurately predict the positions of the free surface and active-passive interface, the mixing index, and the orientation properties. Deviations in the velocity fields may occur due to the worse flowability of coarse-grained particles near the free surface. The efficiency is significantly improved by the coarse-grained model compared with the corresponding original case (the same DEM code without a coarse-grained model was used for the original simulations).