- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

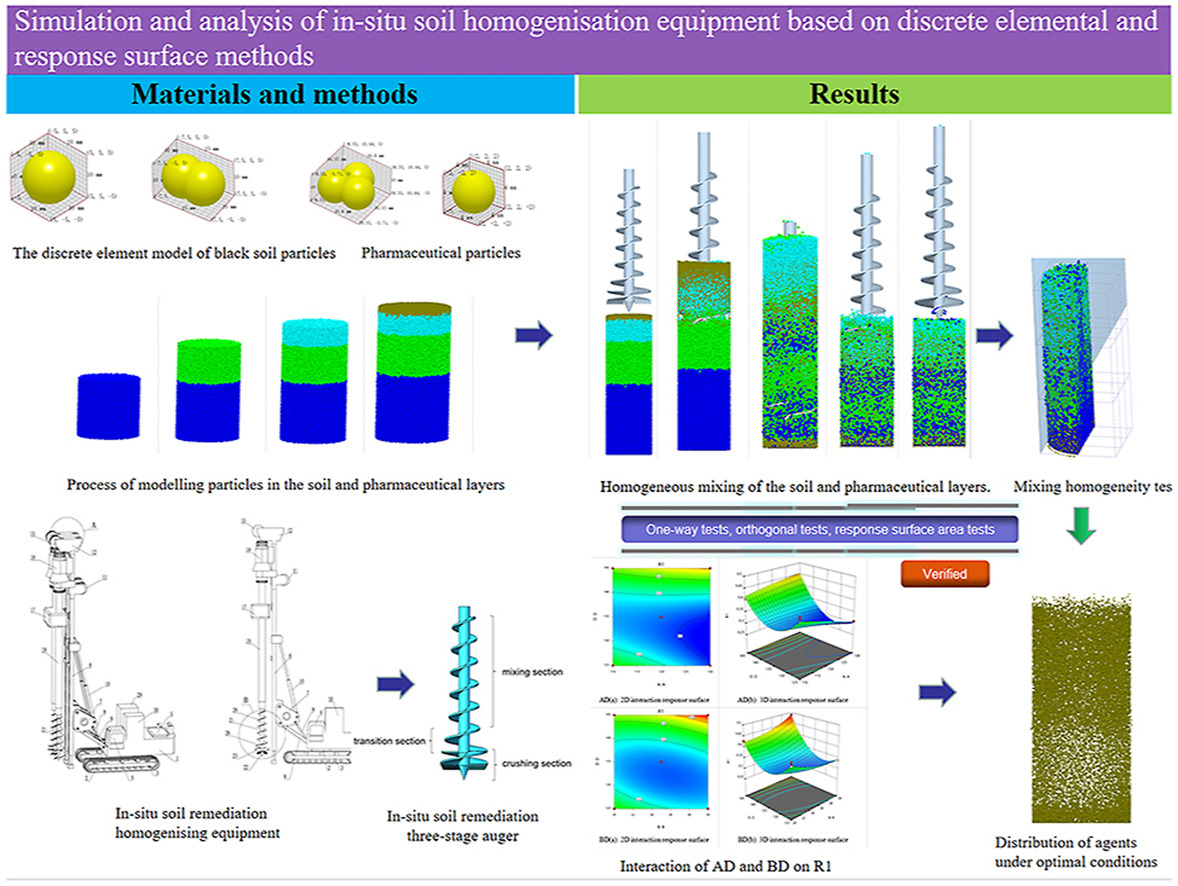

• Use one-way, orthogonal, and response tests to find the best combination of parameters.

• DEM is capable of predicting particle flow in soil remediation plants.

• Mixing time has little effect on the overall mixing uniformity accuracy.

• Improved mixing uniformity in soil remediation units.

• Provides some reference value for the design of soil remediation equipment.

Currently, rotary drilling is one of the main pieces of equipment used for in-situ remediation of contaminated soil. However, this equipment has problems such as uneven mixing and low utilization efficiency, which affect the efficiency of in-situ soil remediation. To improve the efficiency of in-situ soil remediation, this paper takes contaminated black soil as the research object, and the structural design of the new three-stage soil remediation auger is carried out based on SolidWorks. The mixing process of soil and heavy metal passivator under different motion and structural parameters was investigated by the discrete element method (DEM) and response surface methodology. The experimental design was based on rotational speed, homogenizing mixing time, crushing section pitch, and homogenizing section pitch as factors, and soil fragmentation ratio, the coefficient of dispersion, and torque as optimization indices. The kinematic and structural parameters of the three-stage auger drill bit were then optimized using the one-factor method, the orthogonal test, and the response surface methodology, respectively. The test method uses a one-way test to determine the central level value of the orthogonal test and a comprehensive balance method to determine the best combination of parameters for the orthogonal test, which is then used as the central value of the response surface test for parameter optimization. The optimal combinations of kinematic and structural parameters of the three-stage auger drill bit are determined and validated using response surface methodology. The optimum combination of parameters was found to be a speed of 129 rpm, a homogenizing mixing time of 24 s, a pitch of 165 mm in the crushing section, and a pitch of 132 mm in the homogenizing section. The error between the optimal value of the predicted model using the response surface method and the actual simulated value under the optimal parameters is 4.2%, 4.9%, and 5.3%, respectively. The optimized factor parameters provide a reference for the design of the structural and kinematic parameters of the in-situ homogenization equipment.