- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• GPU-enhanced DEM method is applied to investigate the die filling process.

• Forced powder feeding is proposed to mimic the feeding action of a tablet press.

• Effect of stirrer design on the filling performance is systematically explored.

• The optimal stirrer design is identified for the current feeder configuration.

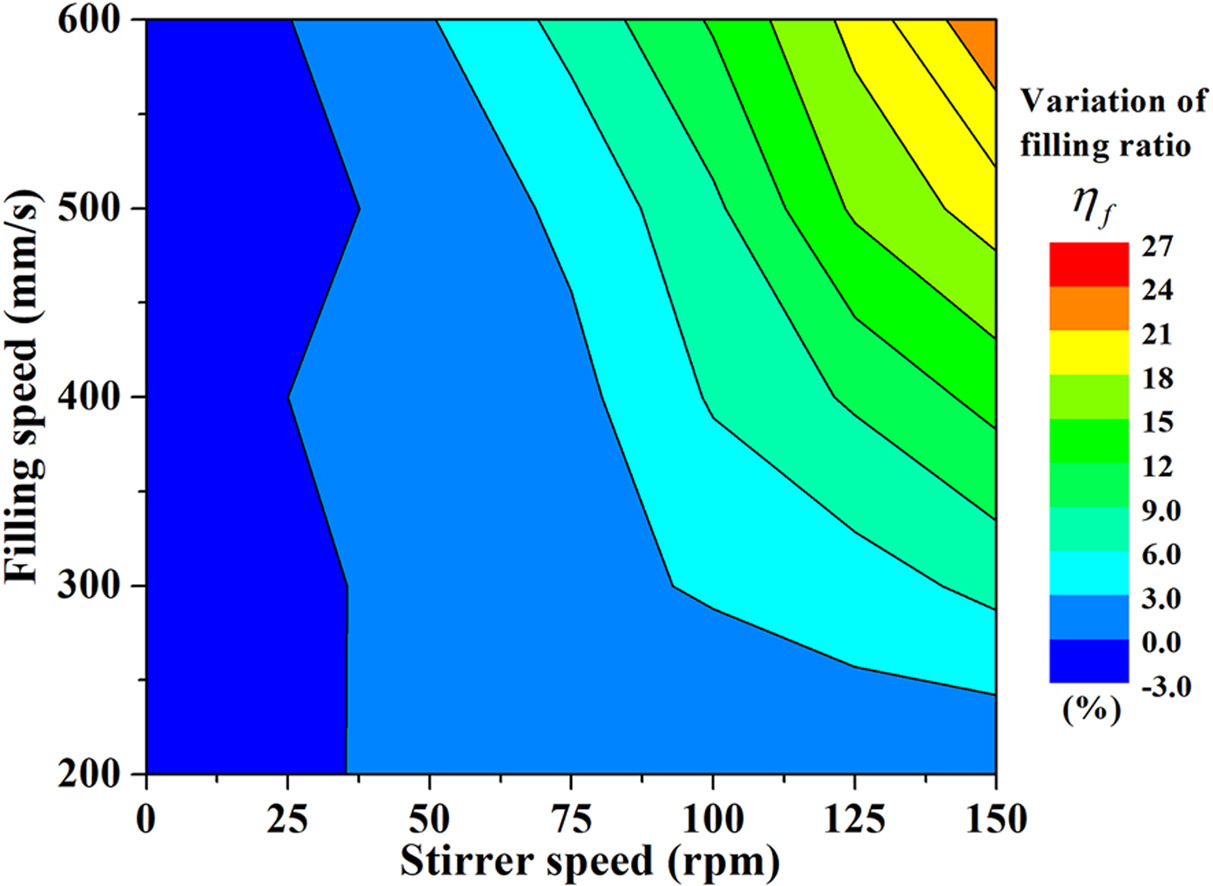

Die filling is a critical stage during powder compaction, which can significantly affect the product quality and efficiency. In this paper, a forced feeder is introduced attempting to improve the filling performance of a lab-scale die filling system. The die filling process is analysed with a graphics processing units (GPU) enhanced discrete element method (DEM). Various stirrer designs are assessed for a wide range of process settings (i.e., stirrer speed, filling speed) to explore their influence on the die filling performance of free-flowing powder. Numerical results show that die filing with the novel helical-ribbon (i.e., type D) stirrer design exhibits the highest filling ratio, implying that it is the most robust stirrer design for the feeder configuration considered. Furthermore, die filling performance with the type D stirrer design is a function of the stirrer speed and the filling speed. A positive variation of filling ratio (ηf>0%) can be ensured over the whole range of filling speed by adjusting the stirrer speed (i.e., increasing the stirrer speed). The approach used in this study can not only help understand how the stirrer design affects the die filling performance but also guide the optimization of feeder system and process settings.