- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

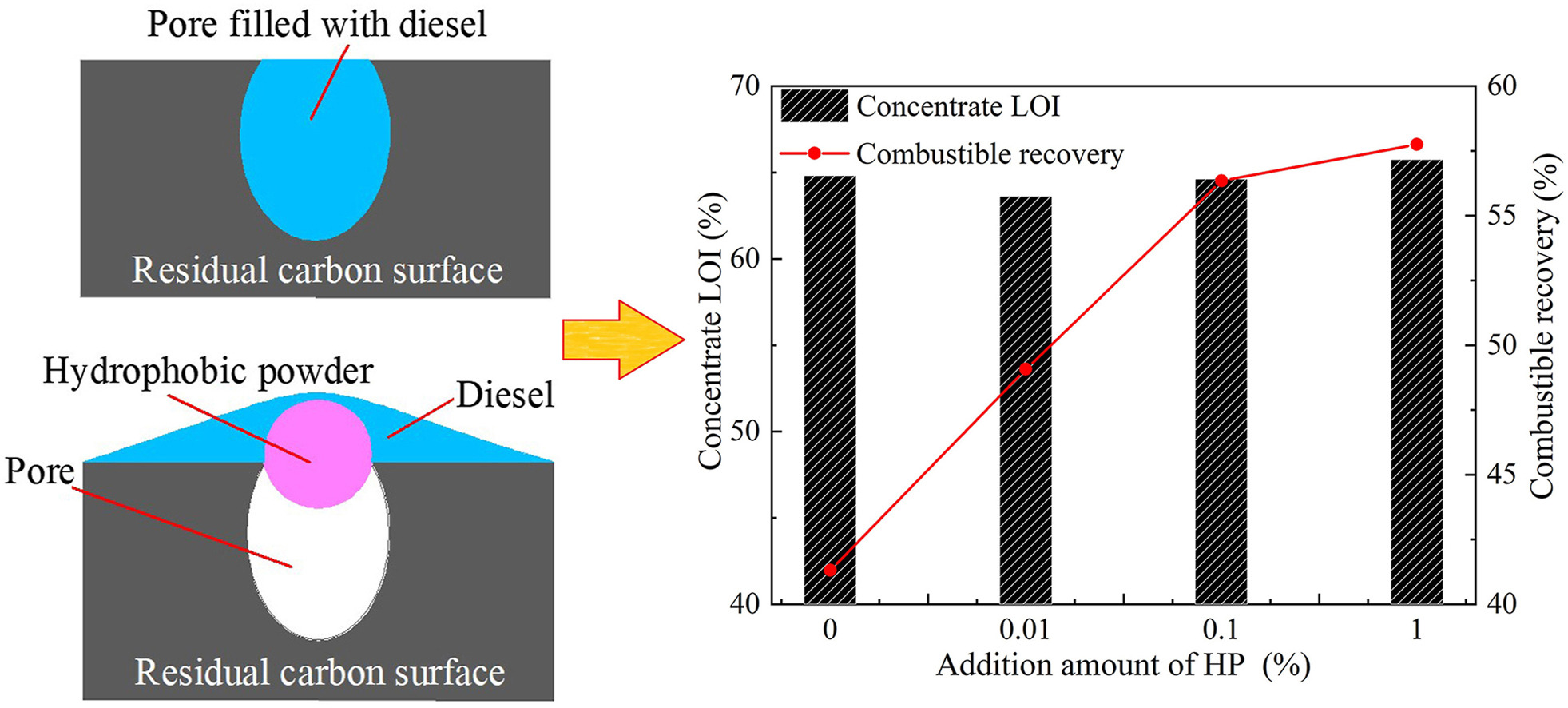

• The proposed novel collector promotes carbon flotation recovery from gasification waste.

• This novel collector creatively mixes diesel with hydrophobic powders.

• Hydrophobic powders reduce diesel adsorption into pore channels by blocking them.

• Hydrophobic powders adsorbed on carbon surface provide sites for diesel adsorption.

Coal gasification fine slag (CGFS) is a solid waste containing residual carbon and ash generated during the coal gasification process, and the separation of the two components is the essential way to realize its environmental pollution reduction and resource value increase. Froth flotation is the preferred method for separating CGFS, but there is a barrier of low carbon recovery in this process due to the extensive adsorption of collector by the well-developed pores on residual carbon. In this study, a sufficiently simple yet innovative collector, a mixture of hydrophobic powder and diesel, was proposed in an attempt to break the bottleneck. Flotation experiments with common diesel and this novel collector were performed respectively, and FTIR, XPS, and SEM-EDX were employed to analyze the collector action mechanism. Flotation results revealed that the novel collector could significantly improve the residual carbon recovery; test results demonstrated that the novel collector could increase the hydrophobic functional group content on the fine slag surface, and the hydrophobic powders in this novel collector mainly appeared at the pore openings of the flotation concentrate. The essence of the mechanism is that the hydrophobic powders play a dual role of blocking pores and providing adsorption sites, thus facilitating the spreading of diesel on the carbon surface and promoting its floatability. The study can provide creative ideas for the efficient disposal of coal gasification waste.