- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

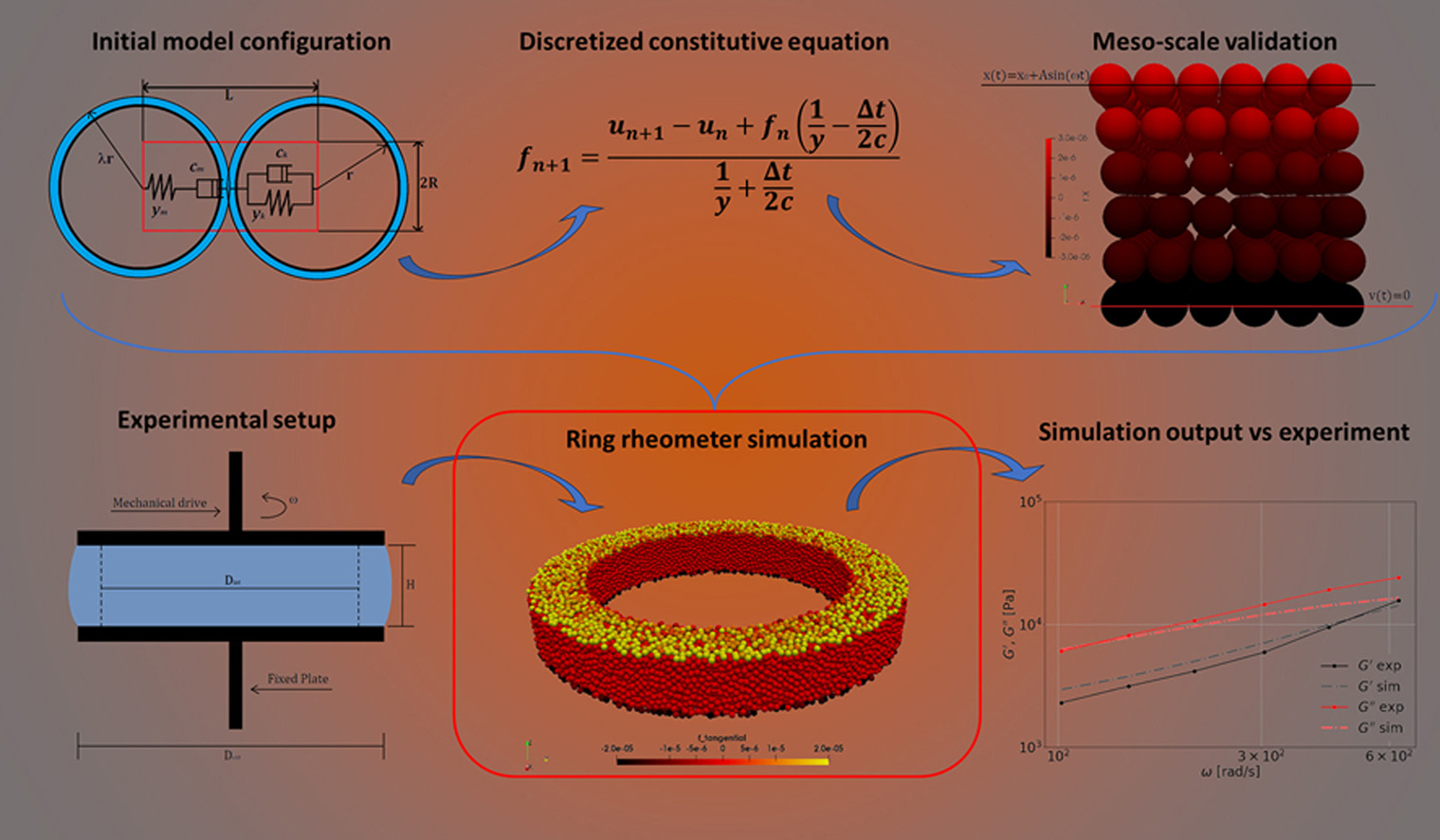

• New DEM based model implemented to account for materials behaving viscoelastically.

• Accuracy and validity of the model tested against analytical solutions of simple mechanical tests.

• Calibration of the model parameters on a wide range of materials with different behavior showing good flexibility.

• Good agreement between simulation and experimental data both in simple and complex systems for multiple materials.

This work focuses on implementing a particle-based method able to characterize viscoelastic materials whose rheological properties, such as storage modulus G' and loss modulus G'', are known. It is based on the bonded particle model, with the elastic constitutive relation here substituted with a viscoelastic one to capture time-scale effects. The Burgers model, vastly used in literature to model viscoelastic systems, is discretized and implemented. The test case used for calibration comprises of a cubic lattice, sheared with a periodic motion, to mimic the effect of a shear rheometer. After appropriate filtering of the stress response, the rheological properties are obtained, highlighting the effect of the lattice geometry, as well as the particle size, on the accuracy of the model. Moreover, the Burgers parameters are calibrated by analytically fitting the experimental dataset, showing the limitation of the Burgers model. The micro-contact parameters are obtained from the macro parameters through appropriate scaling. After completing a frequency sweep, the simulated G' and G'' show a relatively large error, around 25% for G’ for example. For this reason, a more robust model, namely the generalized Maxwell model, has been implemented. The calibration procedure is performed in the same fashion as for the Burgers model. Moreover, the tangential micro-contact parameters are scaled w.r.t. the normal ones. This scaling parameter, called α, is calibrated by minimizing the root mean square error between simulation and experimental data, giving errors below 10% in both G′ and G″ for a large dataset. Additionally, a full ring plate-plate rheometer setup is simulated, and the simulation is compared with the given experimental dataset, again finding a good agreement.