- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

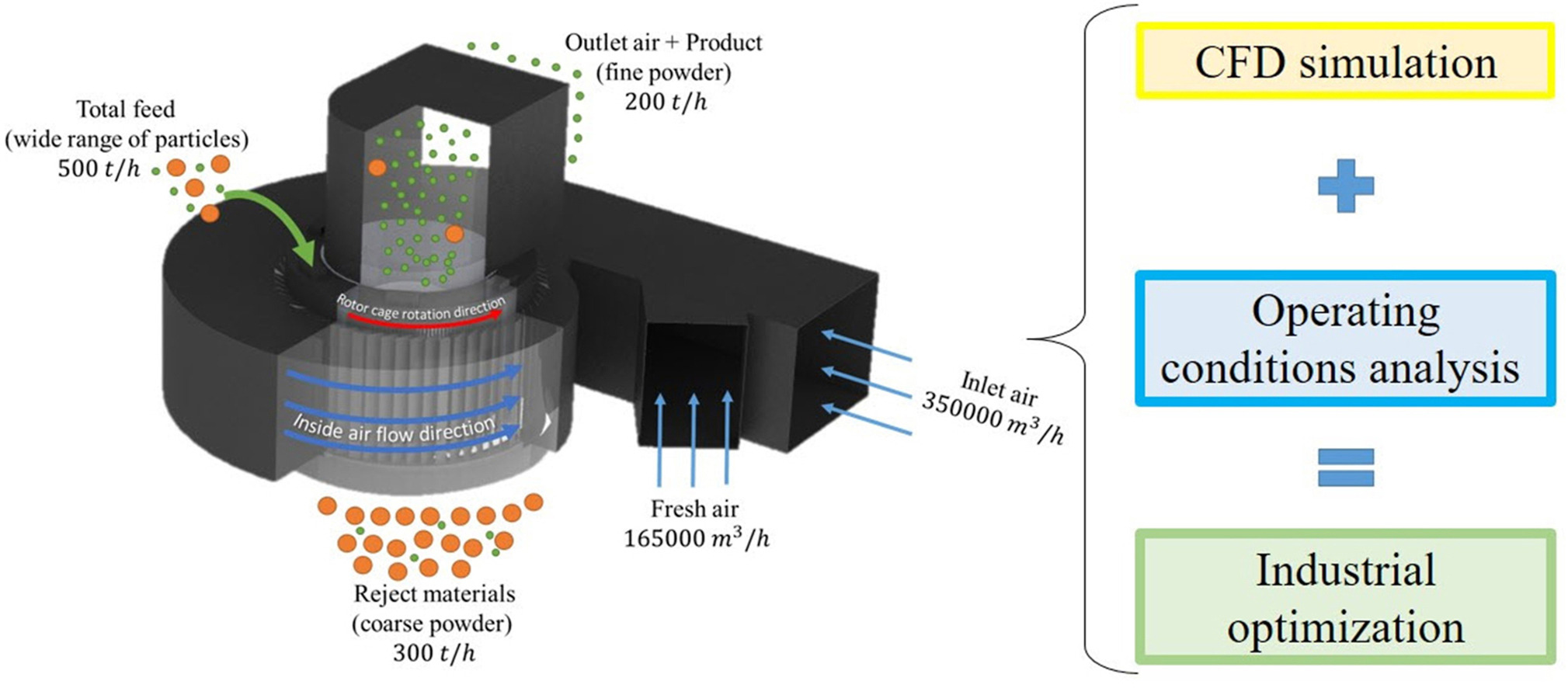

• An industrial cement air classifier performance was studied by CFD simulation.

• Cement quality and production were inspected based on particle size distribution (PSD) analysis.

• Classifier feeding was modified based on flow analyzing inside the classifier.

• The effect of the pressure difference was investigated for the first time.

• The effect of inlet air temperature on the performance of the device was clarified.

An air classifier is one of the main and effective devices in cement industry. In this study, a three-dimensional, steady and two-phase (solid-gas) computational fluid dynamics (CFD) simulation was performed to optimize the performance of this device in the Kerman Momtazan cement plant, Iran. After the validation of CFD results, the air flow field and air path lines between fixed blades were checked carefully and the non-uniformity in velocity distribution and the formation of vortex flows between the blades close to particle inlets were observed. The study tried to improve the device efficiency by changing the method of entering particles into the device, resulting in a reduction in air classifier electrical energy consumption (from 41 to 35 (kW h)/t) and an increase in production rate (from 203 to 214 t/h). Additionally, the study investigated the effects of other modifiable operating conditions like rotary cage rotation speed, pressure difference, and inlet air temperature on the particle size distribution and classifier efficiency. The results showed that increasing the cage rotation speed decreased the product rate and the product particles mean diameter while increasing pressure difference or increasing temperature increased the product rate and the product particles mean diameter. It was concluded that these modifiable operating conditions can significantly affect the performance of the air classifier in the cement industry.