- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Zeta potential significantly influences the sedimentation speed of the particles.

• High-modulus zeta potential prevented the formation of agglomerates.

• Zeta potential was not a relevant factor for yield stress or plastic viscosity.

• The high zeta potential modulus of the particles reduced the setting time of the paste.

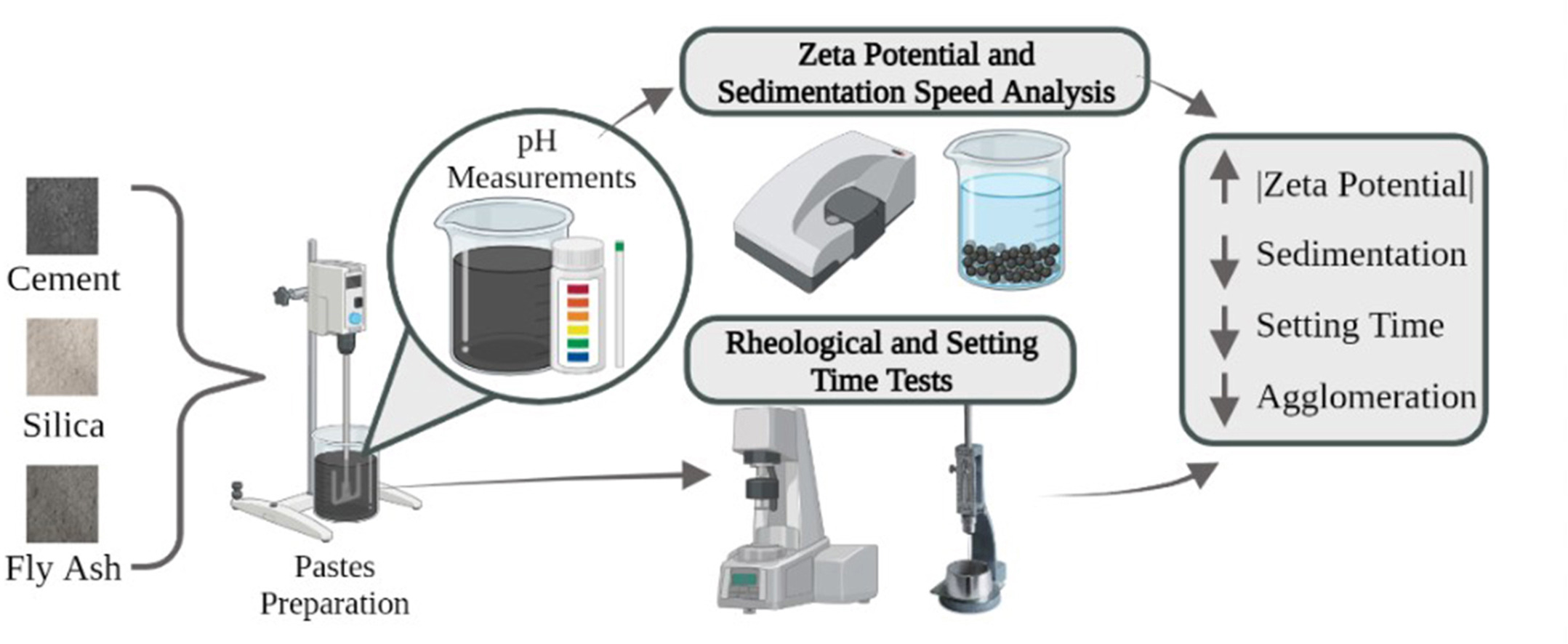

This study investigates the influence of waste characteristics, especially zeta potential, on the properties of cement pastes and solutions. The focus is to evaluate the impact of the zeta potential of cement particles and waste materials on the sedimentation speed, rheology, and hardening time of stabilized cement pastes. Portland Cement II F 40, retarder additive, silica, and fly ash were used in the research. The pastes were prepared, and during the stabilization period, their rheological properties and pH were evaluated. The zeta potential and sedimentation speed of the cement and waste particles were measured at the pH that the pastes presented during the entire stabilization period. After the stabilization period, the pastes were subjected to the hardening time test. The zeta potential analyses revealed diverse values for the different powder types, with the cement particles exhibiting a zeta potential of −3.0 mV, the silica particles exhibiting −10.5 mV, and the fly ash particles exhibiting −20.3 mV. The influence of the high zeta potential modulus was observed on the sedimentation speed, with the solution containing fly ash exhibiting a speed of 40.01 μm/s, whereas the solution containing only cement exhibited a speed of 99.38 μm/s. In the pastes, the results indicate that the presence of fly ash particles with a significantly negative zeta potential led to a 16% reduction in hardening time compared to particles with a lower modulus of zeta potential. Rheometry tests showed that the inclusion of fly ash particles prevented the formation of agglomerates. Although the zeta potential influenced agglomerate formation and hardening time, it was found to have no effect on yield stress or viscosity.