- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

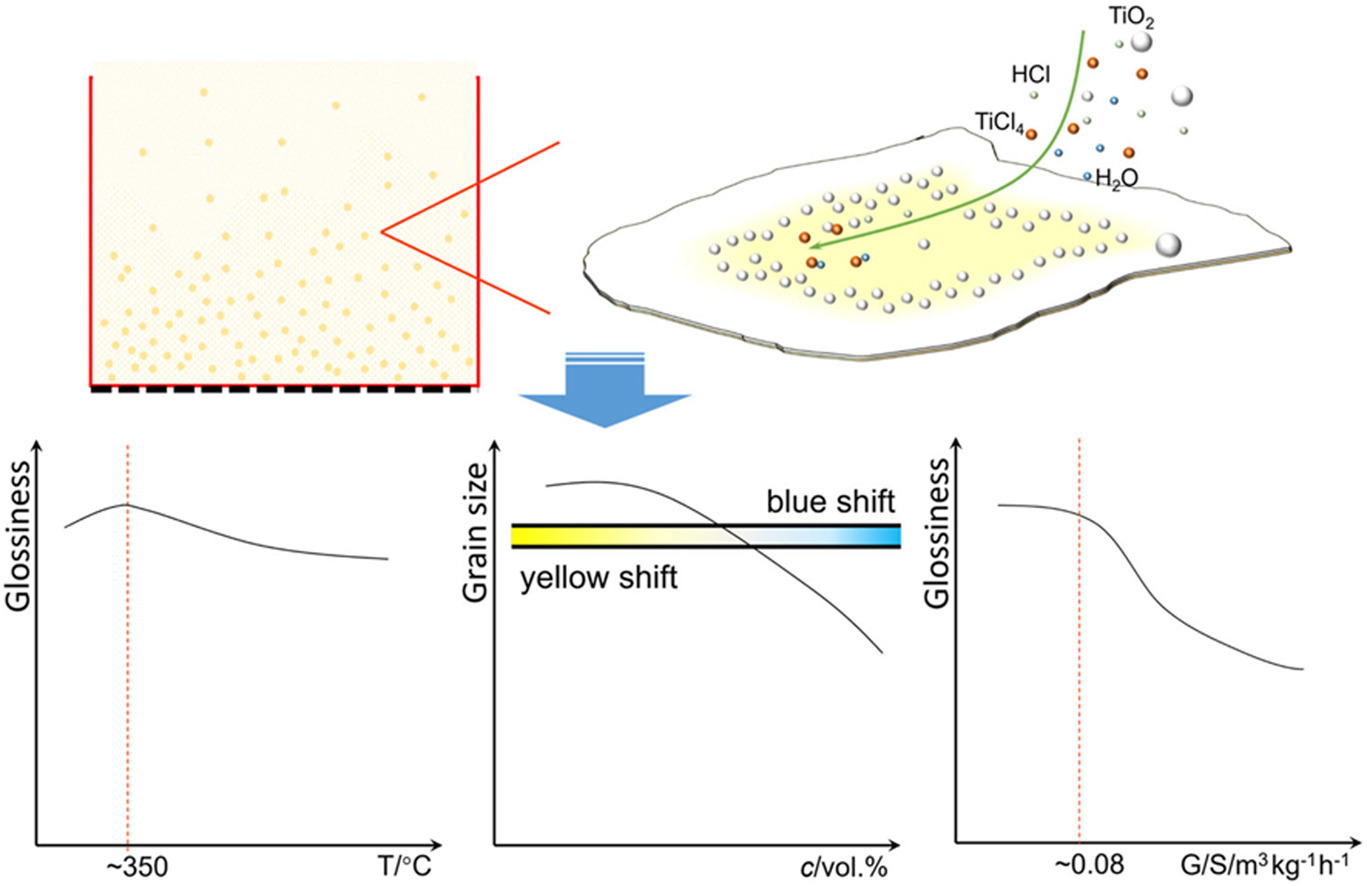

• TiO2 films with high crystallinity show sharp surface and poor glossiness.

• The grain size can be decreased only when largely increasing the TiCl4 concentration.

• Free particles attached on the surface of pearlescent pigment decreased with gas–solid ratio.

• The color of pearlescent pigment can be changed by film thickness and grain size.

Two critical parameters: Glossiness and chromaticity space of pearlescent pigments were evaluated based on crystallinity and grain size. Both the roughness and the vertical distance evolution along the surface of deposited TiO2 film are affected by the crystallinity. The optimal crystallinity of TiO2 was deposited at the temperature of 350 °C. The TiCl4 concentration effectively changed the grain size. However, the high flow rate of fluidizing gas and optimal gas–solid ratio (<0.11 m3/(kg h)) restricted the change of TiCl4 concentrations in fluidized bed reactor. In this case, the grain size of the deposited TiO2 film was about 55 nm. Depending on the grain size, the color of pearlescent pigments was adjusted by controlling the film thickness based on TiO2 concentration. Finally, the silver pearlescent pigment with high glossiness was prepared by chemical vapor deposition method in a fluidized bed reactor.