- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

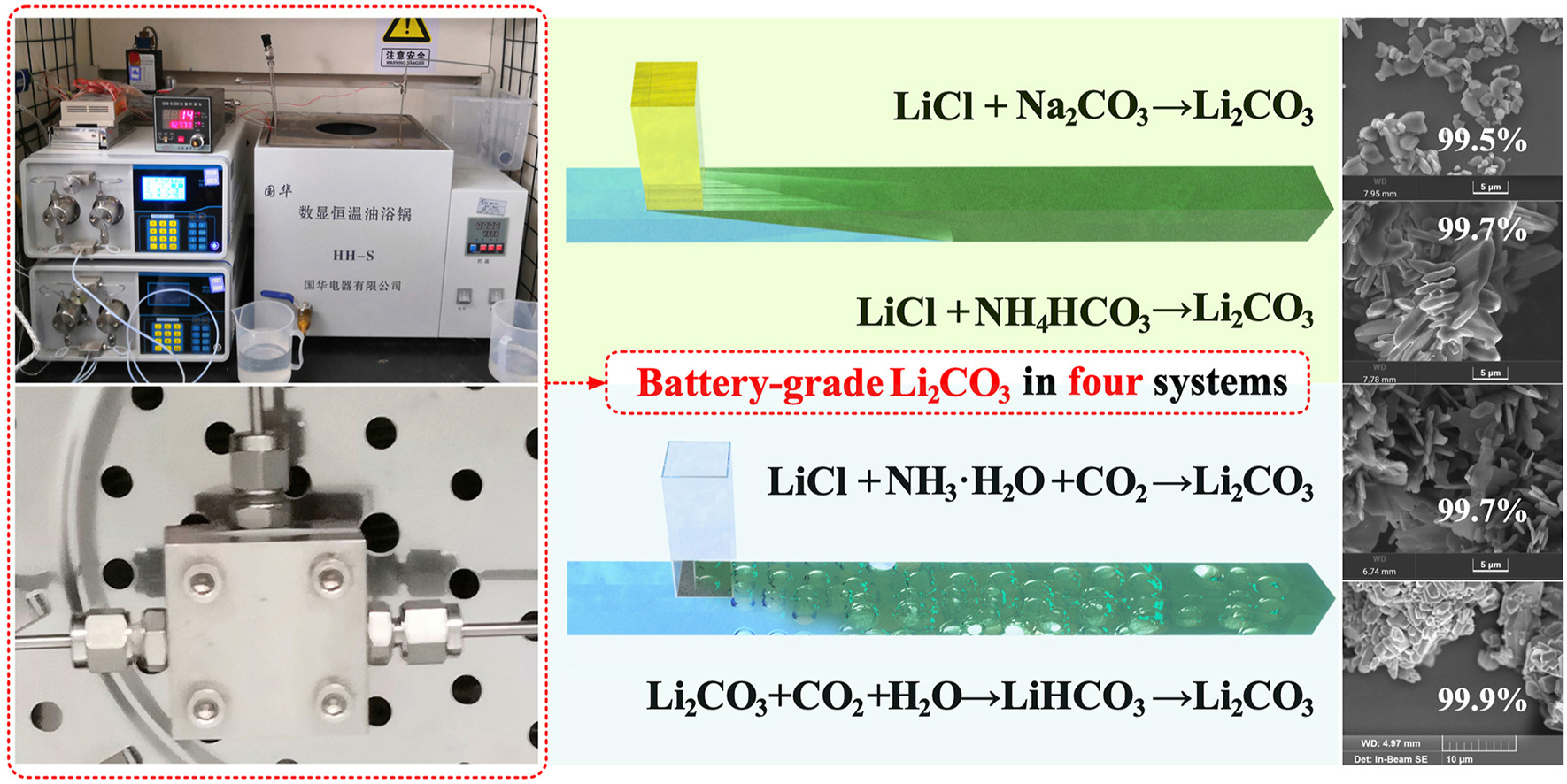

• Battery-grade Li2CO3 particles were prepared with microfluidics.

• A membrane dispersion microreactor was used to enhance mass transfer.

• Synthetic systems of Na2CO3–LiCl, NH4HCO3–LiCl and NH3·H2O−CO2−LiCl were adopted.

• Li2CO3 particles with a size of 3–5 μm were prepared.

• A purity of 99.7–99.8 wt% was achieved in the ammonia-based systems.

Battery-grade lithium carbonate (Li2CO3) with a purity of higher than 99.5 wt% is of great importance as a high value-added lithium salt. However, influences of different reaction systems and process control on product purity remain unclear. Herein, a membrane dispersion microreactor was used to enhance the mass transfer of preparation and purification processes in homogeneous and heterogeneous system. Synthetic systems of Na2CO3–LiCl, NH4HCO3–LiCl, and NH3·H2O−CO2−LiCl, CO2 purification based on carbonation and decomposition were adopted. The Li2CO3 purity was increased by the improvement of mixing performance. The carbonation time was reduced by 62.5% and 58.3% for the NH3·H2O−CO2 and CO2 purification systems, respectively. In the two ammonia-based systems, Li2CO3 particles with a purity of 99.7–99.8 wt% were one-step prepared with a size of 3–5 μm, which also met the requirement of the battery-grade standard. The purity was further increased to 99.9 wt% by CO2 purification and LiHCO3 decomposition. The investigation could provide a feasible alternative for the controllable preparation of battery-grade Li2CO3 in one or multiple steps.