- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

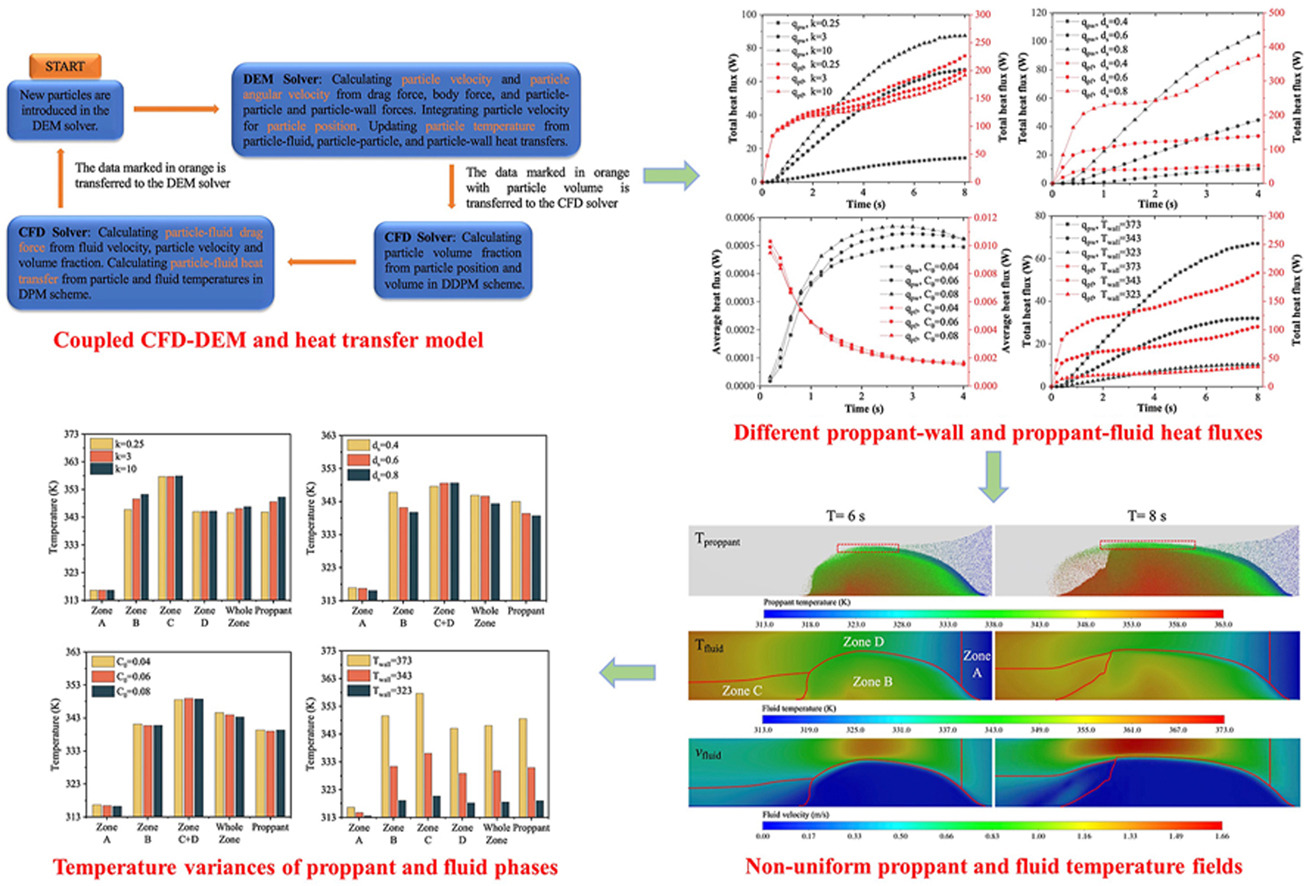

• A coupled computational fluid dynamics-discrete element method and heat transfer model is employed.

• Temperature fields for fluid and proppant phases are accurately characterized.

• Proppant–wall, proppant–fluid, and fluid–wall heat transfers are evaluated.

• Effects of proppant bed shape on the temperature fields are investigated.

• SC-CO2 volume expansion under various conditions is assessed.

The non-uniform temperature distribution in supercritical CO2 (Sc-CO2) fracturing influences the density, viscosity, and volume expansion or shrinkage rate of Sc-CO2, impacting proppant migration. This study presents a coupled computational fluid dynamics-discrete element method and heat transfer model to examine the effects of proppant bed shape and the heat transfers of proppant-wall, proppant-fluid, and fluid-wall on the fluid and proppant temperature fields. The Sc-CO2 volume expansion is assessed under various temperature conditions by evaluating the volume-averaged Sc-CO2 density. Several factors, including proppant size, shape, thermal conductivity, concentration, temperature difference, and injection velocity, are carefully analyzed to elucidate their impacts. The findings elucidate the existence of four distinct zones in the fluid temperature field. Each zone exhibits different magnitudes of temperature change under diverse conditions and undergoes dynamic transformations with the development of the proppant bed. The fluid-wall heat transfer and the fluid temperatures in Zones C and D are significantly subject to the fluid injection velocity (governing the heating duration), the temperature difference between fluid and formation (impacting the magnitude of heat flux), and the proppant bed shape (controlling the effective heating area). Additionally, the proppant-wall and proppant-fluid heat transfers determine the temperatures of both the proppant bed and the fluid within Zone B, showing a strong correlation with proppant thermal conductivity, proppant size, injection velocity, and temperature difference. The proposed coupled model provides valuable insights into the temperature distributions and flow behaviors of temperature-dependent fracturing fluids and proppants.