- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

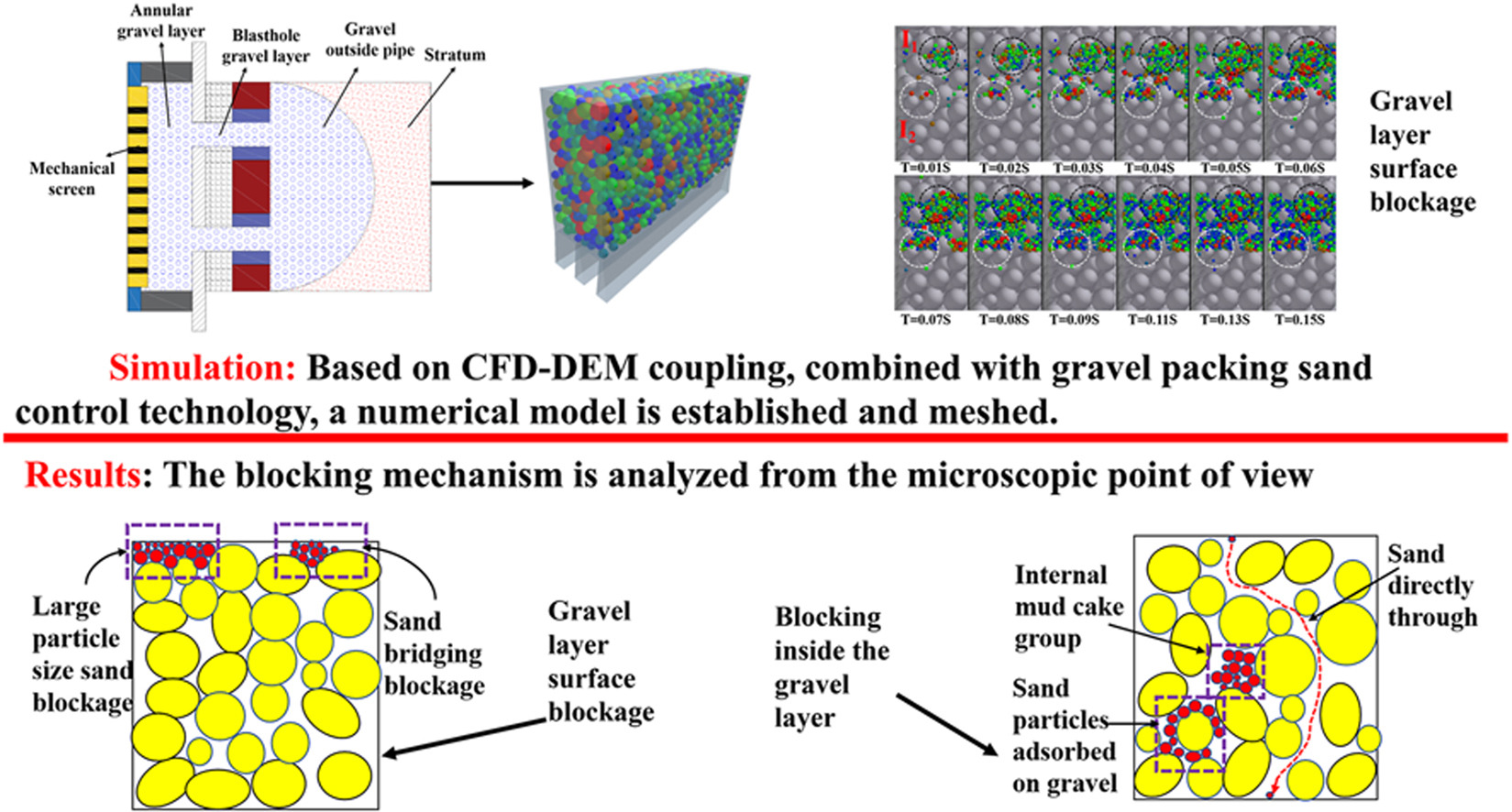

• Blocking process of gravel packing sand control (GPSC) is studied numerically.

• Migration mode of sand particles in gravel layer is analyzed microscopically.

• The blocking area is divided to understand the blocking mechanism of GPSC.

• The influence of structural parameters on GPSC was systematically studied.

Gravel packing sand control (GPSC), as the optimization of mechanical sand control technology, is widely used in the deep water completion and sand control of loose sandstone heavy oil reservoirs and highly argillaceous. To explore the blocking mechanism of GPSC, the influence of its structural parameters on the blocking of GPSC is investigated. This paper establishes a particle element model based on computational fluid dynamics-discrete element method coupling using the discrete element method and establishes a fluid flow model combined with computational fluid dynamics to realize their full coupling solution. And sand control experiments were carried out using a micro visual sand control simulation device to verify the blocking model. The blocking mechanism is analyzed from the microscopic point of view, and then, the influence of sand control structure parameters on the blocking in GPSC design is evaluated. The results show the following: (1) the blocking process of GPSC can be divided into three stages: an initial stage, sand accumulation stage, and equilibrium stage. (2) There are two main types of gravel packing blockage. The first type of blocking is blocking on the surface of the gravel layer. Sand particles on the surface of gravel layer mainly exist in the form of large particle size blocking gravel pores and sand particles bridging each other. The second type of blockage is the blockage inside the gravel layer. Sand particles mainly exist in the form of internal mud cakes and adsorption on gravels inside the gravel layer. (3) To ensure the sand control performance of the gravel layer, the gravel layer thickness is designed between 23 and 28 mm. The displacement or pressure of the on-site packing pump should be increased to ensure that the gravel layer packing solidity ranges between 59% and 62%. In the design of GPSC, it should be ensured that the median particle size of gravel is 5–6 times the median particle size of sand. This study provides an effective technical reference for the design of gravel structural parameters in on-site gravel packing completion sand control.