- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

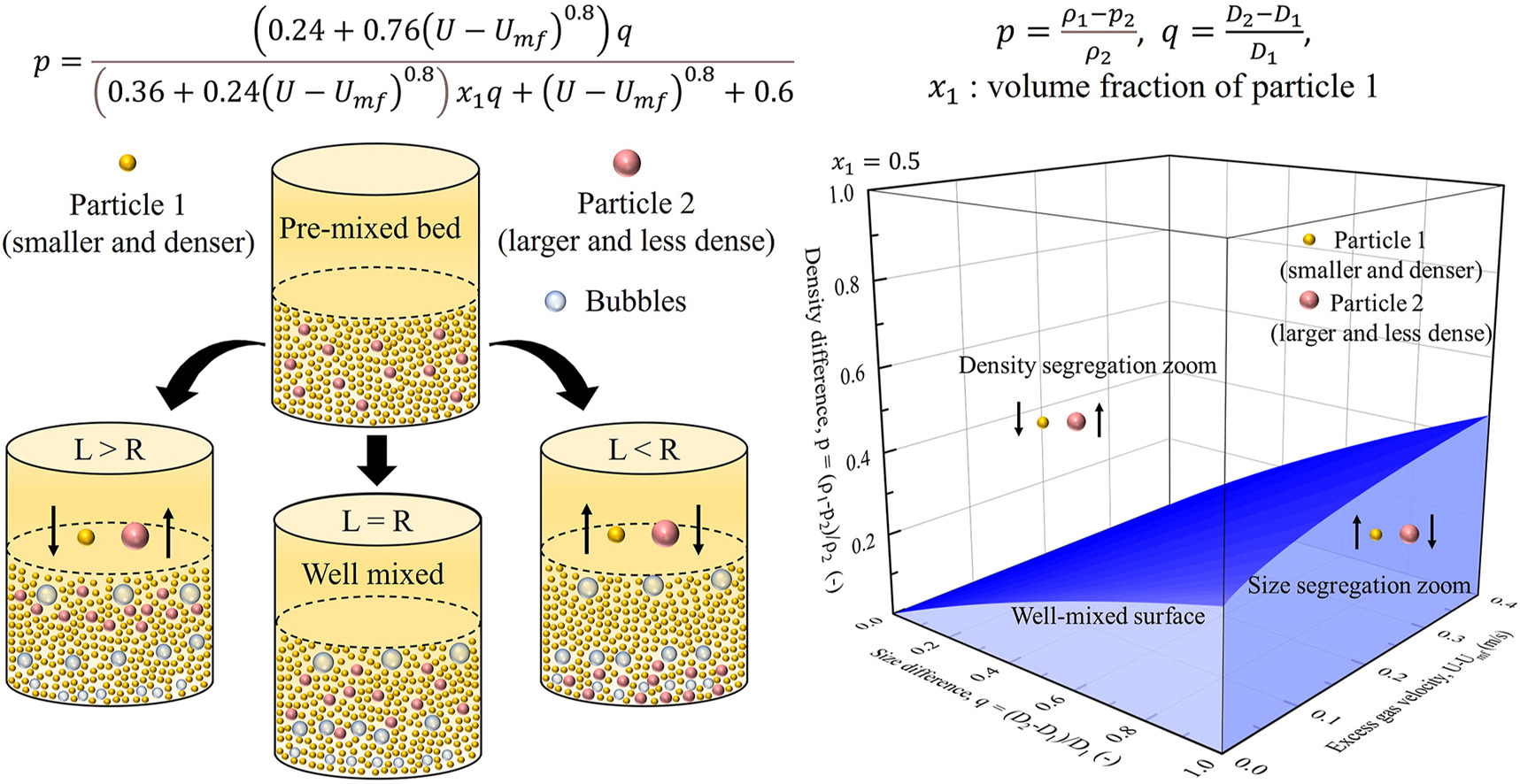

• Comprehensive analysis of mixing and segregation factors in binary fluidized beds.

• The development of a predictive model for bubbling fluidized bed segregation directions.

• Segregation reversal induced by variations in gas velocity or bed composition.

• Demonstration of good validity under gas velocities less than 3.2 times minimum fluidization velocity.

In gas fluidization processes involving different types of particles, the mixing or segregation behavior of the solid mixture is crucial to the overall outcome of the process. This study develops a model to predict the segregation directions of binary mixtures of Geldart B particles with density and size differences in bubbling fluidized beds. The proposed model was established by combining the particle segregation model, a previous particle segregation model, with a derived bed voidage equation of the bubbling fluidization based on the two-phase theory. The model was then analyzed with different function graphs of the model equations under various conditions. The results indicated that an increase in gas velocity or volume fraction of larger particles would strengthen size segregation, causing the larger and less dense components to descend. To validate the model, 42 sets of data collected from 6 independent literature sources were compared with the predictions of the model. When the gas velocities were below 3.2 times the minimum gas velocity, the predictions were consistent with experimental results. This study has shed new light on the mechanisms of particle segregation in binary fluidized systems and provides a theoretical foundation for designing and manipulating gas-solid fluidized reactors.