- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

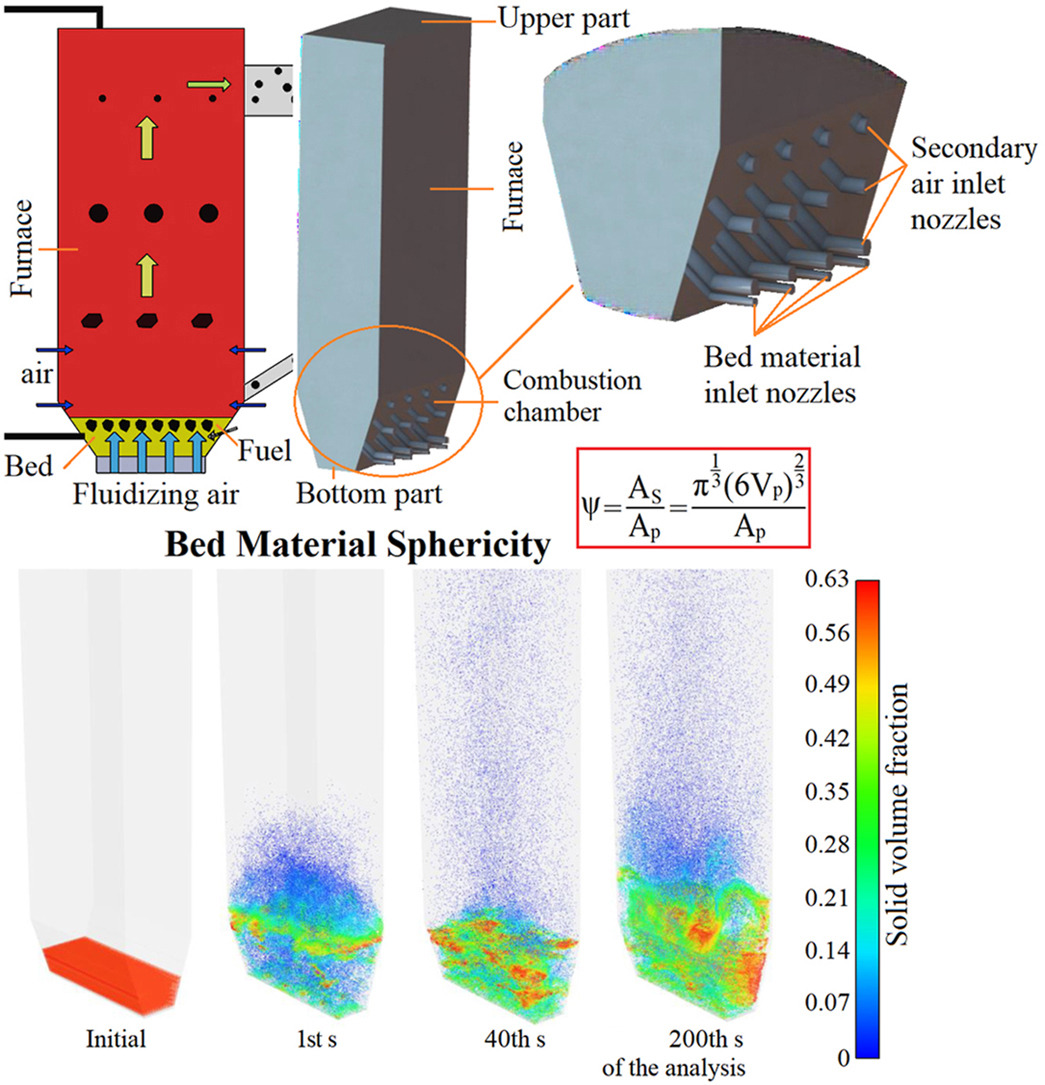

• Investigates the influence of bed material sphericity on combustion processes.

• Examines mole fractions of CO2, CO, H2O, and O2 within the circulating fluidized bed boiler (CFBB).

• Analyzes temperature, pressure, NOx, and SO2 distributions in the CFBB.

• Explores the potential for reducing energy consumption in the boiler.

• Emphasizes the enhanced combustion efficiency associated with lower sphericity.

This study delves into the combustion behavior of various lignite types within a circulating fluidized bed boiler (CFBB), with a primary focus on the impact of different bed material sphericity ratios (0.5, 0.7, and 0.9). Utilizing bed material with a sphericity ratio of 0.9 sourced from the Çan power plant and verified through experimentation, the research reveals several key findings. Notably, furnace temperatures tended to rise with higher sphericity ratios, albeit with variations between lignite types, particularly highlighting the complexity of this relationship in the case of GLI-Tunçbilek lignite. Pressure levels in the combustion chamber remained consistent across different sphericity ratios, indicating minimal influence on pressure dynamics. Improved combustion efficiency, especially at the bottom of the boiler, was observed at lower sphericity levels (0.5 and 0.7) for Çan lignite, as reflected in CO2 mole fractions. While NOx emissions generally decreased with lower sphericity, the sensitivity to sphericity varied by lignite type, with Ilgın lignite showcasing low NOx but high SO2 emissions, underscoring the intricate interplay between lignite properties, sphericity, and emissions. Overall, this study advances our understanding of CFBB combustion dynamics, offering insights valuable for optimizing performance and emissions control, particularly in lignite-based power.