- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

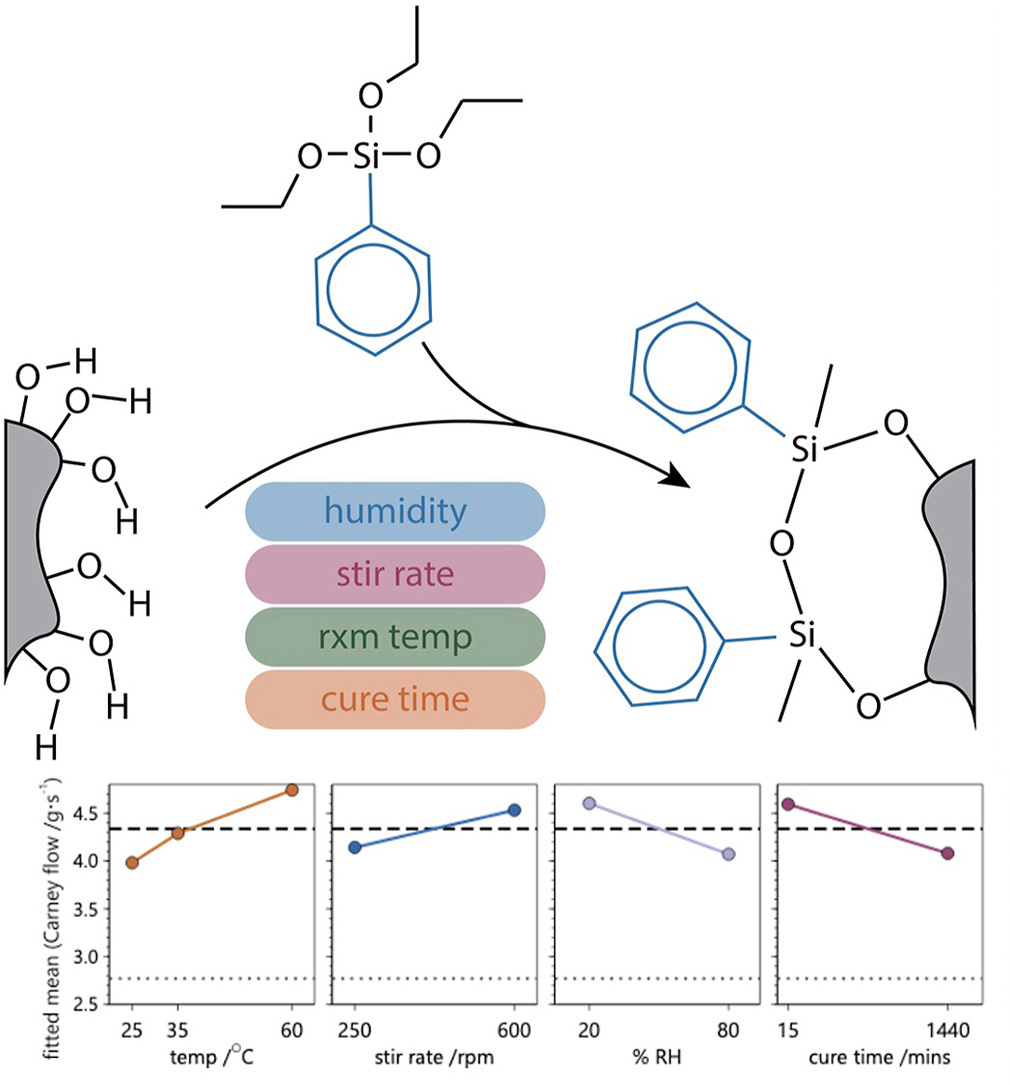

Analysis of synthetic parameters for coating aluminum powders with phenyltriethoxysilane coupling agent and their effects on powder flow behavior

• Silanization occurs over a wide range of humidity, cure time, and temperature.

• Apparent density of coated particles depends on reaction temperature and cure time.

• The flow properties show no significant dependence on silanization conditions.

Though silanization of aluminum powder is currently used to improve its flow properties, for use as an alternative fuel source, there are a wide range of experimental parameters for the process and not all of them have been thoroughly explored. Until this is complete, it is unknown if the process is optimized in terms of time, efficiency, and effect. Herein, we report on a study into the effects of changes in humidity, degree of agitation, reaction temperature, and curing time upon the deposition of phenyl triethoxysilane into 20 μm (d50) aluminum particles. We confirm the deposition of the coating via diffuse reflectance infrared spectroscopy and x-ray photoelectron spectroscopy. We then characterize the coated particles using apparent density measurements and Carney flow methods. Using analysis of variance, we find that, of the parameters explored, only changes in cure time and reaction temperature provide meaningful changes to the apparent density, while none of our parameters produced statistically significant changes in Carney flow values. Thus, we conclude that, when optimizing silanization of aluminum particles, environmental control of humidity is unneeded and that the reaction can be run with minimal agitation. The ability to largely ignore these parameters is a benefit to large-scale processing.